Results 31 to 40 of 59

-

01-12-2015, 12:21 AM #31Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

What is the stone you are using?

The poster was using a 16K Shapton stone.

That stria and edge look much more course and we are not talking about 80 grit to lap we are talking about 400 grit.

Most of us use a 325 DMT and it works just fine.

I have been using a 300 grit I Wood plate lately and it works even better than my old DMT. Lapped a 20k Guyokomo with it new and it is producing very nice finished edges, I shave comfortably off the stone.

Some .125 CBN does improve it a bit more.

-

01-12-2015, 01:20 AM #32

Sorry guys, even though it may not be that big a deal, I use a 325 DMT, not a Atoma 400.

A fool flaunts what wisdom he thinks he has, while a wise man will show that he is wise silently.

-

01-12-2015, 02:23 AM #33

Well I guess we can all agree 80 grit wetndri is not a good lapping medium for finishing stones.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

01-12-2015, 03:22 AM #34Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yea, the guy that kicked this off, was mjwit, who lapped a 16K Shapton with a 400 Atoma.

It does not really matter as synthetics can be lapped with any thing from a 300 up to 1200 Diamond Plates, with about the same results, though clearly lower grits will be much faster than higher grits.

-

01-12-2015, 04:26 AM #35

Ahhh, yes I see now. Sorry got a little confused about who u were talking about and when. Now I see. Never mind my ignorance. Oh and before I forget thanks guys this discussion really has helped me a lot when it comes to understanding my technique and stones better.

A fool flaunts what wisdom he thinks he has, while a wise man will show that he is wise silently.

-

01-12-2015, 06:35 AM #36Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

As noted in the post, all edges shown are finished on an 8k Shapton Pro. The 80 grit wet/dry obviously is not optimal, that's the point I'm trying to make. I just don't have a new diamond plate to demonstrate, so had to make do with what I had available. A new diamond plate of any grit lower than 800 is WORSE than the 80 grit wet/dry. Once they break in a 325 is fine. Even a DMT XXC is fine. Look back and see what I said - if the 8k/16k guy is using a new, not well-worn diamond plate, that could explain the whole issue. (He did say he was sent a brand new DGLP to try, which is definitely going to produce a coarser finish vs. a more worn plate ). The sharp diamonds really do produce a bad finish, as well as allow pieces of stone to break away and act as slurry. The net result is a coarser finish and a very rough feeling edge.

The fewer laps you do with a coarser lapped stone the worse the finish will be. More laps lets the stone revert closer to its natural texture, as I stated earlier.Last edited by eKretz; 01-12-2015 at 06:43 AM.

-

01-12-2015, 02:08 PM #37

A fool flaunts what wisdom he thinks he has, while a wise man will show that he is wise silently.

A fool flaunts what wisdom he thinks he has, while a wise man will show that he is wise silently.

-

01-12-2015, 02:20 PM #38Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

More laps! Or break the diamond stone in a bit by going at it on a chisel or something like an Arkansas stone for a short while. Once the diamond plate is broken in a bit the diamonds get slightly rounded or flattened, and at that point the coarseness of the diamond plate makes much less difference to the imparted finish, (though still affects it a bit) but will still affect the cutting speed/aggressiveness a decent amount. (Coarser diamond plate lap will get the stone to cut faster).

Here are a few more shots from my testing. Only concentrate on the finish nearer the edge. You can see that the scratches are fewer and shallower as the lapping gets finer even with worn diamond plates, but not nearly as significant as it would be with a new plate.

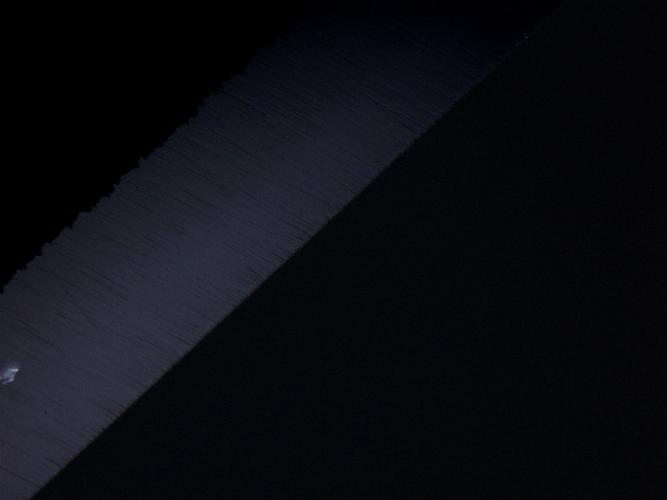

Well-worn DMT XXC lapped stone:

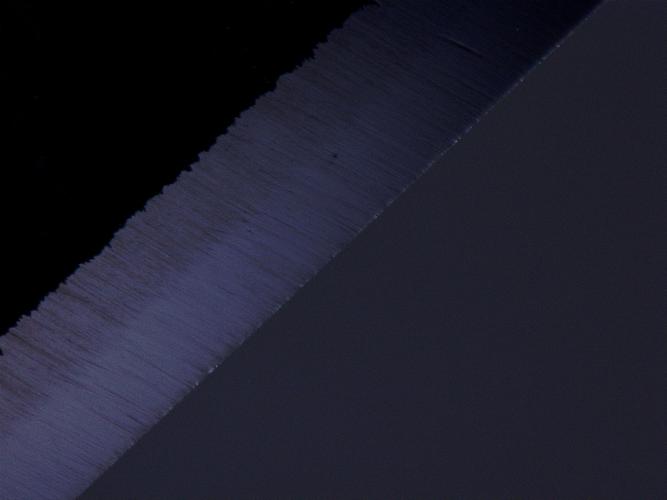

Well-worn Atoma 140 lapped stone:

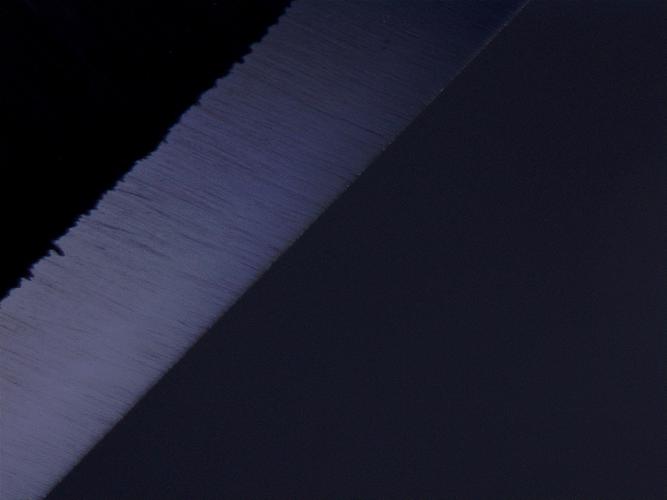

Well-worn Atoma 400 lapped stone:

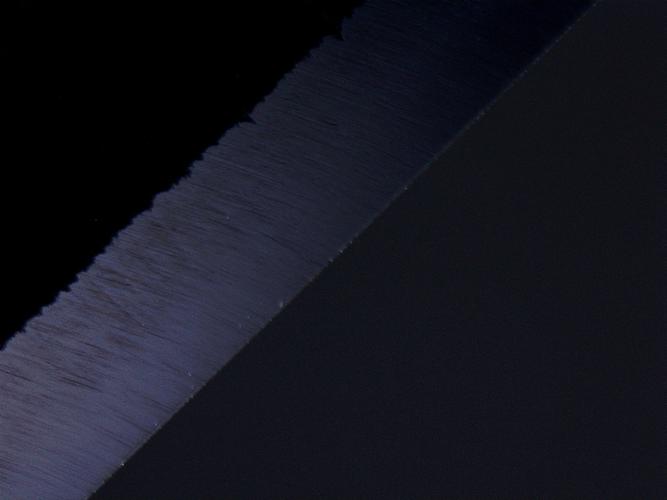

High-grit synth lapped stone:

Last edited by eKretz; 01-12-2015 at 02:27 PM.

-

01-12-2015, 02:32 PM #39Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Here are shots of the actual lapped stone surface showing surface texture with the different lapping coarsenesses.

80 Grit SiC:

Very Worn DMT XXC:

Worn Atoma 140:

Worn Atoma 400:

High grit Synth:

This last is interesting because you can see that the softer synth stone wears the binder away faster than the abrasive particles, leaving them slightly proud of the binder, whereas the diamond lapping levels the entire surface of the stone evenly.

Also note the difference between the DMT XXC and Atoma 140 - both in the stone surface texture and in the bevel/scratch pattern near the edge. Even though the DMT is a coarser plate, mine is so worn that it produces a finer finish on both the stone surface and the imparted finish on the razor.Last edited by eKretz; 01-12-2015 at 02:38 PM.

-

01-13-2015, 02:07 AM #40

You're using unrealistic examples for lapping plates. Nobody uses 80 grit wetndry for a final finish on a stone, same as a 140 grit Atoma. Well actually I use a 140 grit Atoma but only on 220-320grit stone.

I believe the op did not use an Atoma so that's really another discussion.

The op's problem is possibly one of pressure when honing, tho why would he use more pressure on 16k over 8k ?

Or the 16k stone could be faulty. If he has lapped both the 8k & the 16k with the same plate it is fair to assume the 8k should show a coarser finish.The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote