Results 1 to 10 of 61

-

07-27-2015, 09:19 PM #1Member

- Join Date

- May 2015

- Location

- Australia

- Posts

- 33

Thanked: 1 My first honing attempts with photos

My first honing attempts with photos

Little background. I purchased my first ever straight razor, a brand new 4/8 Thiers Issard, honed shave ready and I managed to shave with it perhaps 10 times before the edge degraded. Most probably due to my stropping.

Just last month I bought a USB microscope and Welsh slate "Dragon's Tongue" to learn to hone with.

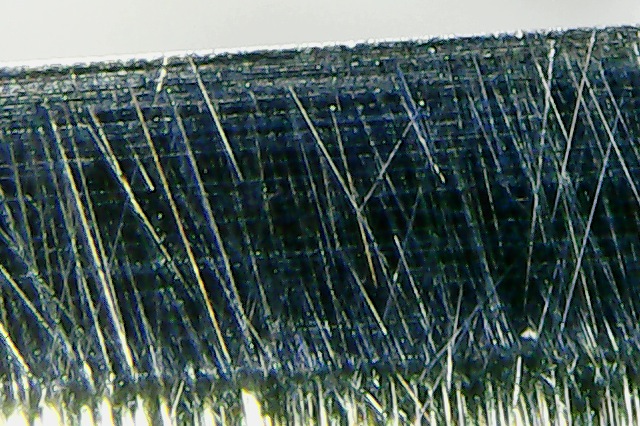

^^^50x and 500x magnifications of the edge after my ten shaves and before any honing attempts.

For my first hone I tried the drmatt357 coticule method under running water. It seemed to improve the edge but not enough to shave with it.

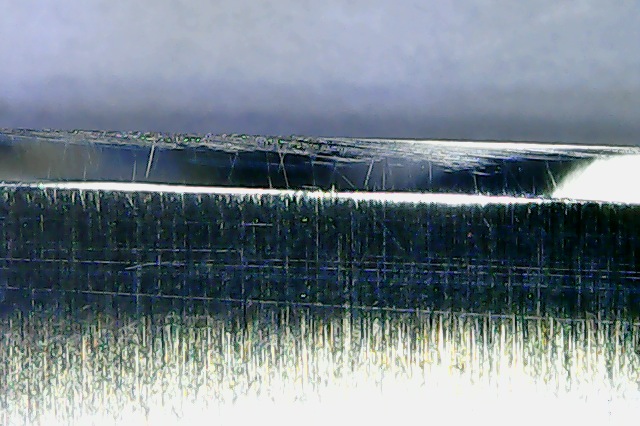

^^^After my first hone. 500x magnification.

Tried another time but this time following the Lynn Abrams one stone method on youtube. Starting with heavier slurry and progressively diluting it. No change in edge. Saw more youtube videos and tried the Lynn Abrams one stone method third time and fourth time. Took again microscope photo and saw some changes that I'd like to hear experts opinion on.

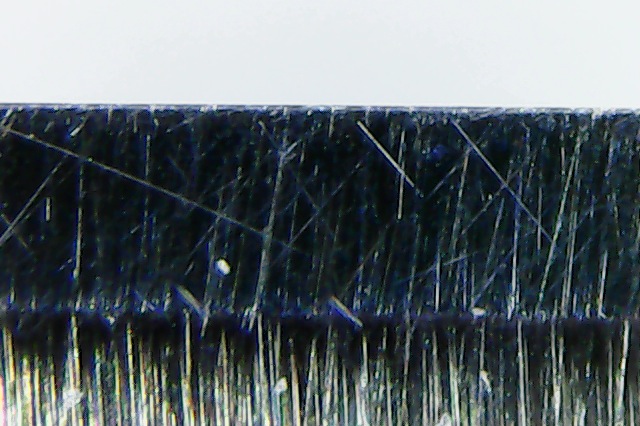

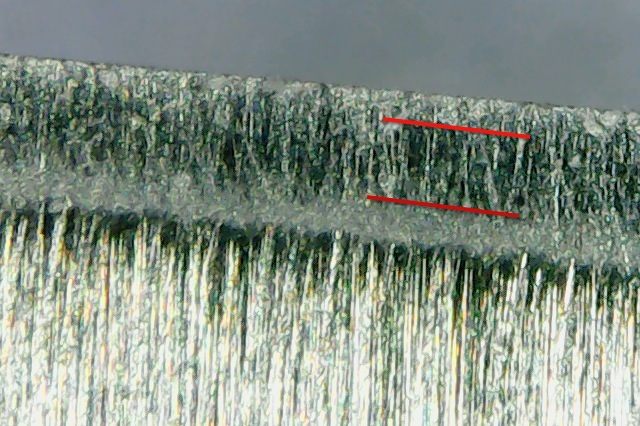

^^^After fourth hone. 500x magnification.

Is the darker area between the red lines where I am removing material? Why is this uneven? Am I using too much pressure so the edge is flexing? Has the razor been honed with taped spine before and I should do that too?

I have another razor and Feather AC to shave with. I promised I will not buy more until I have learned the basics of honing.... and I am really desiring to purchase a nice Ralf Aust with dark wood scales.

In an attempt to avoid too much of trial, error and frustration, maybe someone could point me to the right direction in my studies.

Many thanks in advance!

-

07-27-2015, 09:46 PM #2

Well, one thing I would like to point out is that you are using a method that has a higher degree of difficulty. The bevel in the last photo looks to be in complete, meaning you still have a bit of the old polish left over from the original bevel and maybe from your other honing attempts. If it were me I would restart with a 1,000 grit hone to clean up the bevel. Also, TIs can be tricky to hone.

From their stillness came their non-action...Doing-nothing was accompanied by the feeling of satisfaction, anxieties and troubles find no place

-

The Following User Says Thank You to Mephisto For This Useful Post:

elmoensio (07-28-2015)

-

07-27-2015, 09:56 PM #3

Ask for help there in Norway and suck up the pride, honing is easy , till it ain't to quote a great one,, all you should have needed was a refresh , 6-10 laps to start ,, very light laps if your hone is a finisher,, I don't know if your stone can go back as a one stone hone without a few hundred laps, but really there are a couple guys in Norway. Tc

“ I,m getting the impression that everyone thinks I have TIME to fix their bikes”

-

The Following User Says Thank You to tcrideshd For This Useful Post:

elmoensio (07-28-2015)

-

07-27-2015, 10:03 PM #4

First, "Am I using too much pressure so the edge is flexing?".. you should not be using ANY pressure. (Yes, there are times when varying degrees of pressure may be used, but this is not one of them - especially when first learning to hone.) You need only that minimal amount of pressure needed to keep the blade in full contact with the stone.

Second, you should try the Sharpie Test - mark the edge with a sharpie, give the blade half a dozen strokes on the stone, and take another look. This will tell you if you are getting to the very edge. It is possible that the razor was honed with tape but with the amount of work you have described, that bevel angle should be long gone.

I am also concerned with the 50X "before" picture.. it appears to show some sort of edge damage and possibly some sort of crud on the edge. If you have corrosion or physical damage, the blade needs some work on a coarser stone before finishing. While on that subject, there has been considerable variation in the fineness of the dragon's tongue stones reported & that might not be the best stone for a newcomer's first attempt at refreshing.

It is hard to say what's going on in your fourth hone 500X pic. Evaluating an edge under the microscope is very difficult since a seemingly minor difference in lighting can make a huge difference in what we think we are seeing. I'd suggest the sharpie test with no pressure and a fresh look. There are just too many unknown variables to deal with at this point so let's try to eliminate them one by one.

Don't get discouraged, it takes a little work and then, for most of us, there is that sudden "eureka" moment when everything works. Good luck.

rs, TackI have great faith in fools - self confidence my friends call it.

-

The Following User Says Thank You to Tack For This Useful Post:

elmoensio (07-28-2015)

-

07-28-2015, 08:30 AM #5illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

I'm going to start with random thoughts.

First, what the heck is the "Dr" Matt coticule method?

Second, your microscope images can be extremely deceptive. Most critically, the angle of the light shining on the bevel is going to drastically alter your perception of that bevel.

Regarding the darker area of the bevel, I don't know if it is or is not the area that steel is being removed because, again, it depends on the angle of the light. Regardless, hone until the bevel is uniform and reflects light uniformly.

Finally, your 500x image is not a 500x image.

-

The Following User Says Thank You to Utopian For This Useful Post:

elmoensio (07-28-2015)

-

07-28-2015, 10:49 AM #6

From what I can see your not reaching the edge and even if you was it wouldn't really make a difference.

I think to learn how to hone you could do with the following:

1. A set of stones starting with a 1K to set a proper bevel on.

2. A black marker pen.

3.This forum + Practice.

Keep it up , you will get there

Last edited by JOB15; 07-28-2015 at 10:53 AM.

-

The Following User Says Thank You to JOB15 For This Useful Post:

elmoensio (07-28-2015)

-

07-28-2015, 11:00 AM #7

I think most honers would agree that an edge is best examined during honing with a small hand lens of say 10X magnification, similar to what a jeweller or geologist would use. Higher magnifications from USB microscopes give hard-to-interpret images which, as Utopian and Tack point out, are very subject to variations in lighting.

Using a lower power lens gives a consistent method of examining an edge and observing the effect of each honing stage.

-

The Following User Says Thank You to Maladroit For This Useful Post:

elmoensio (07-28-2015)

-

07-28-2015, 06:03 PM #8Senior Member

- Join Date

- Sep 2014

- Location

- Bulgaria

- Posts

- 840

Thanked: 168

I also think that youre not reaching the edge . Maybe youre using pasted strop .Tape it and see how the scratches will go . The best way is hone on a midle grit stone and finish the razor . Forget abbout numbers and ect . Light to no prsure , more laps if needed . You will know when you are ready on this stone . its instinctive thing .

Shave is a better test than a microscope pics , they could be desceving .

-

The Following User Says Thank You to RusenBG For This Useful Post:

elmoensio (07-28-2015)

-

07-28-2015, 06:15 PM #9Member

- Join Date

- May 2015

- Location

- Australia

- Posts

- 33

Thanked: 1

-

07-28-2015, 06:25 PM #10Member

- Join Date

- May 2015

- Location

- Australia

- Posts

- 33

Thanked: 1

That's what I thought too, all it needs is a refresh. Well, too late for that now. I understood that all natural stones can be used for one stone hone, heavier slurry equals lower "grit" number. Right now, I want to put in the hours to learn honing, not give up after only four attempts.

39Likes

39Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote