Results 11 to 20 of 26

Thread: any help will be appreciated

-

12-24-2015, 07:36 AM #11Truth is weirder than any fiction..

- Join Date

- Jun 2012

- Location

- Land of the long white cloud

- Posts

- 2,946

Thanked: 580

Looks like near wedge to me from previous thread. Post some photos of the whole blade, not just the profile, would help. An hour on a DMT 1200?

Into this house we're born, into this world we're thrown ~ Jim Morrison

-

12-24-2015, 09:04 AM #12

i did exactly the same on it, it had a big crack on the bevel so i did not have any other choice than this procedure. the blade has no smile, it is fine and plane with no cracks or micro crack in the bevel.

to answer about other coms, with 3 or 8 layers, it's only the hone wear touch on the stone and not the bevel. i ask myself if the blade lost too much larger of its and to put it on action, will i need to grind it? because in this way, as i said before the hone wear does not touch the bevel on the hone.

for pictures, i will try to do them this afternoon, otherwise i could only tomorrow night.

-

12-24-2015, 09:23 AM #13Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,331

Thanked: 3228

If I am reading this right, the hone is only touching/working on the shoulder of the bevel and not reaching to the edge even with excessive layers of tape on the spine. I almost think that the blade may be way out in geometry. Sounds like the spine is way too narrow for the width of the blade as it now is.

What is the spine width in mm and width of the blade measured from where the spine contacts the hone to the edge in mm?

BobLife is a terminal illness in the end

-

12-24-2015, 10:00 AM #14

-

12-24-2015, 10:25 AM #15

here some pics,

just marked the edge with black pen

and here, after few passes on 400 grit. as you see there is fine draw, the black mark is gone. but below this line, there is the bevel which does not touch to hone.

-

12-24-2015, 10:50 AM #16

i think when i corrected the crack (about 1.5 mm) the blade lost a lot of his large. i think i just need to regrind it (well i don't have grinder) or continue on DMT because the edge is still not enough fine to have a bevel.

that's the only explanation i can get.

-

12-24-2015, 11:58 AM #17Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,331

Thanked: 3228

Yes, I do think from those measurements that the spine is far too narrow for the blade width as it is now. I think for a 20mm blade the spine should be 5mm to 5.5mm wide to get a good bevel angle. A 4mm wide spine should be for a 14mm wide blade to get a good bevel angle.

I am not an expert and do not know a solution to the problem. I am sure more knowledgeable members of the forum may be able to help.

BobLife is a terminal illness in the end

-

12-24-2015, 01:16 PM #18

I think you are getting that bevel because you were grinding on it with 20 layers of tape. Now you're trying with a few layers and it's going to take a whole lot of work to get that thing set. Did you try to "bread knife" this blade befor honing?

-

12-24-2015, 01:22 PM #19

as i said earlier yes i tried butter knife when i deleted the crack

-

12-24-2015, 04:47 PM #20

well i found a solution, as i said this was a 7/8 wedge with a big crack (almost 2 mm) in the bevel which i corrected. but here is the problem, at least, as the blade lost of largeness there is a inequality to remake the bevel, it must to be regrinded to have a correct bevel.

well i don't have one of these machines. the only way i can, is the lift the spine with some degree for the bevel work on the hone. i just discovered this. the bevel is much better, unless i have a big hone wear which i will need to clean and rehone the blade.

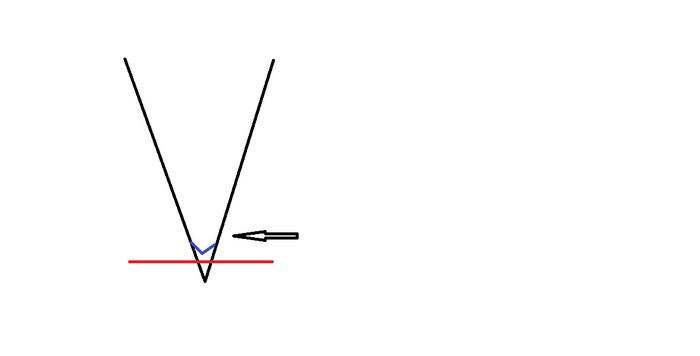

here, there is a picture i made for explain better what i'm talking about;

the red line for show how i shorted the blade for correct the bevel and clean the crack. the blue lines shows the new bevel which can be done without regrind the blade.

if you have ony other idea for this case, share it please.

merry christmas to all

5Likes

5Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote