Results 21 to 30 of 33

Thread: Setting bevel

-

01-05-2016, 11:24 PM #21

Very few razors are ground evenly.

It could be a pressure issue, especially for a new honer but a warped spine or uneven grind will accentuate the bevel shape.

Kamisori are asymmetrical not uneven & the edge bevels should be small especially on the Ura (stamped side). Old worn worn out kamisori can have large bevels.The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

01-05-2016, 11:33 PM #22Junior Member

- Join Date

- Aug 2014

- Posts

- 28

Thanked: 3

That is exactly the point I was making on both counts. The razor is unlikely to be perfectly even on both sides, so chasing perfect bevels on both sides isn't necessary. My caveat being that if it is due to ery uneven pressure then it might lead to issues.

I brought up kamisori as asymmetry is just extreme unevenness from one side to the other. A bevel being wider on one side over the other is just slight asymmetry in my mind, so it isn't too big a deal so long as my caveat of uneven pressure is remembered.

-

01-05-2016, 11:40 PM #23

-

01-05-2016, 11:47 PM #24

-

01-05-2016, 11:57 PM #25

-

01-06-2016, 01:13 AM #26

-

01-06-2016, 02:28 AM #27Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

And this is what I was getting at. With a new honer, my guess is this is more a tell of bad form than imperfection in the blade. It may not be problematic now, but if he continues the same path it may become problematic later. Better to address the bad habit early than allow it to continue and become second nature.

When you're sharpening a chisel is my guess. I doubt a second bevel has much in the way of benefits outside of that realm, since they're one of the few tools I see made with an intentional second bevel.

I second that. When you set the bevel, your edges go from the very edge of the blade all the way to the back of the spine. Taping the bevel for bevel set, then removing it to hone defeats the purpose because now the edge of your bevel won't be touching the hones. In reverse (adding tape after bevel set), it will ever so slightly change the bevel you just worked so hard to set. Best case scenario - you hone your edge the same way you set your bevel. If you set it with tape, replace the tape and continue honing. If you didn't use tape, finish without. Either way, you want your edge to have the same plane from 1k through your finisher. Such is my understanding at any rate, YMMV.

-

01-06-2016, 03:05 AM #28Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

So, typically for a new honer, it is recommended to hone a razor with tape, because they usually have issues getting bevels to meet, use too much pressure and do too many laps. As a result if the bevel is not taped will trash a spine, needlessly and cause more issues with the razor.

The most aggressive stone is the 1k and that is where you want tape.

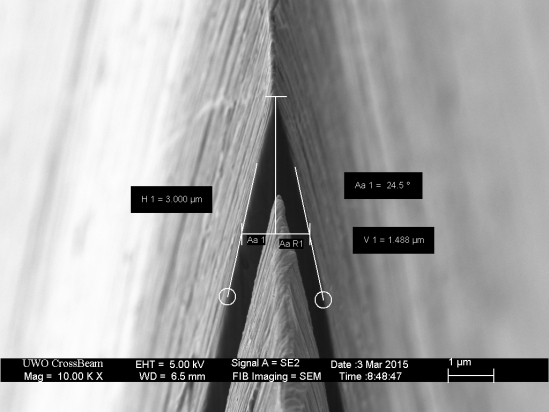

It would be interesting to see your bevel, to see if you even have a double bevel, if you did enough laps on the 4k you probably completely reset it and have a fully set bevel. 4k’s are aggressive.

There are any number of reasons for intentionally making a double bevel, a stronger edge, where chipping is occurring or using a slow hard stone like an Ark where you do not want to produce a full bevel, It can then be repeatedly touched up with a few strokes, until the bevel becomes so large it is almost a full bevel at a shallower angle, or to make a stronger edge.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

pcm (01-06-2016)

-

01-06-2016, 03:38 AM #29

Here....

Exactly. Some people call it a micro bevel and it is done with knives and quite a few here will use it with razors too although they will start with a layer of tape for the bevel set and honing but when they are going to their finishing stone they add one more layer to get the micro bevel. I have never used this method but there are some that swear by this.What a curse be a dull razor; what a prideful comfort a sharp one

-

01-06-2016, 04:00 AM #30< Banned User >

- Join Date

- Dec 2015

- Location

- Calgary

- Posts

- 43

Thanked: 3

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote