Results 31 to 38 of 38

-

01-25-2017, 01:49 AM #31

Scotch (3M) Super 88 here, too. It's a bit thicker and is also used by a certain cantankerous mountain man who lives up in the north woods. Right, Roy?

--Mark

--Mark

-

01-25-2017, 02:14 AM #32Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Hehe, I was kidding about using it for actual electrical work. I like the crimps that have built in heat shrink tubing. Cleaner, neater, more permanent everything proof seal. I only use tape in a pinch, or as a means to keep wires tucked inside those black plastic tubes with a slit down the side for keeping wires in order. Guess it's one of those, 'You know you've been working on cars too long when..." affairs.

-

01-25-2017, 04:09 AM #33

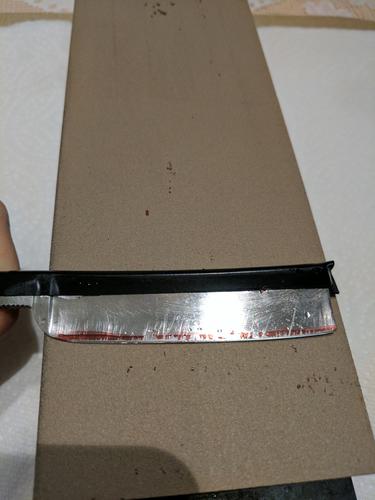

Two layer tape + red marker ready to hone!

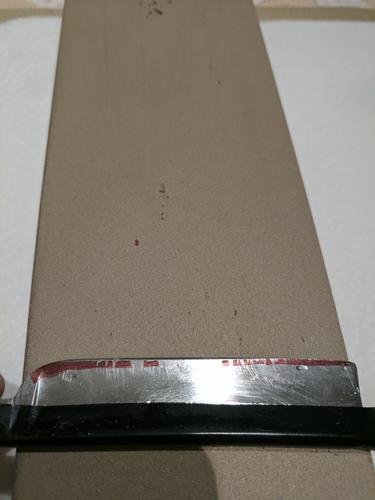

After some x-strokes to check how to marker paint look

After several x-strokes:

Last edited by cmsessa; 01-25-2017 at 04:11 AM.

-

01-25-2017, 04:36 AM #34

First and foremost; End your tape at the stabilizer instead of allowing it to go on down the tang.

Also, give this a try:

http://straightrazorpalace.com/hones...than-mile.htmlOur house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

Gasman (01-25-2017)

-

01-25-2017, 04:46 AM #35

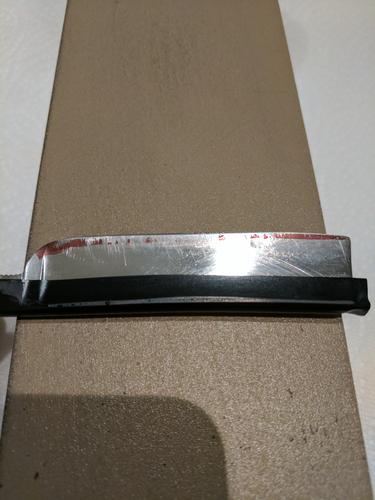

I did a couple of strokes more.

I think this side is kind of finished:

On This side, getting a bevel on the toe is driving me crazy!

Roy: I will check your link now

-

01-25-2017, 01:59 PM #36

Nice link Roy. If i continue to have an issue with the Boker im working on, im going to give this 1" line and rolling x stroke a try.

It's just Sharpening, right?

Jerry...

-

01-26-2017, 07:43 AM #37

Update:

Yesterday after talking a bit with Roy I figured out certain things I was not doing correctly:

- Pressure. I should have put more pressure on the toe.

- I wasn't focus in parts of the bevel which require more attention

After some video watching I came back home today and finished the whole process.

My steps this night:

1) With two layers of tape I started on the 1k focusing on the toe. After I got to what I considered a more equal bevel, I did 10-20 strokes on the 1k.

2) Since the tape was a bit worn out, I changed it. In the process, the SR slip and I cut myself

1,2,3,4...10. Cool, they are all there, let's keep going!

3) I moved to 4k. Did a couple of passes. When using the magnifier I noticed the heel was kind of dull. I applied some pressure to the heel and did a couple of more passes.

4) Moved to 8k. Not sure what needs to happen to go from 4k to 8k but I felt that it was almost ready.

5) 50 lapping strokes

Here's how it looks in the end:

I did a shave test and it felt much better than expected.

I will return this razor to BJ and see what he thinks about it

Thanks for reading!

-

01-26-2017, 05:25 PM #38Senior Member

- Join Date

- Aug 2014

- Location

- East Central Illinois

- Posts

- 782

Thanked: 101

56Likes

56Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote