Results 11 to 20 of 61

Thread: Razor shoulder catching on hone

-

07-06-2017, 02:17 PM #11Member

- Join Date

- Dec 2012

- Location

- Portsmouth, UK

- Posts

- 33

Thanked: 0

-

07-06-2017, 02:49 PM #12

-

The Following User Says Thank You to ejmolitor37 For This Useful Post:

Grenage (07-06-2017)

-

07-06-2017, 03:04 PM #13

I had this issue with some of my razors when i was starting out. can confirm that Grenage's method is what i landed on for the fix. takes some getting used to, but as a secondary benefit it's also good for making the most of your hone real estate as well. good luck!

-

07-07-2017, 12:06 AM #14Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yup. Was your technique, lack of tape, too much pressure and way too many laps.

A strip of tape could have prevented the massive hone wear. You were/are honing on the stabilizer and even the tang.

Trying to get the heel on the stone, (the Stabilizer was keeping it off the stone), you applied more pressure and ground the spine down and the heel square.

The heel now needs correction, as outlined in the thread posted in post, 2, and at least 2 layers of tape on the spine to make up for the steel ground off the spine.

Repair the heel, moving the corner well forward of the stabilizer, put 2 layers of tape on the spine and re-set the bevel.

If you don’t re-shape the heel, you will form a heel hook, that will cut you and probably grind more of the spine and heel away.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Grenage (07-07-2017)

-

07-07-2017, 01:04 AM #15Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

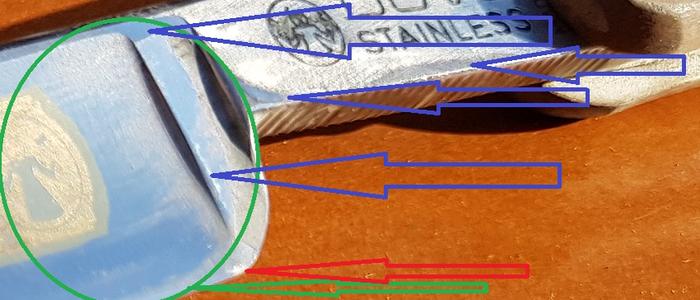

The Blue arrows are where you are grinding on the spine over the stabilizer, on the stabilizer and the tang. All of these areas will keep the heel edge off the hone.

The Red arrow is where the edge corner is currently ending, already into the stabilizer, which will keep the heel off the hone or make a heel hook.

You must reshape the heel to hone it.

The Green circle is the new radius, notice how re-shaping to this profile will move the corner forward about 6MM, (Red Arrow)

-

-

07-07-2017, 10:05 AM #16Member

- Join Date

- Dec 2012

- Location

- Portsmouth, UK

- Posts

- 33

Thanked: 0

Ah thank you; I appear to have really done a number on the thing; looking at the opposite side, there's more taken off the toe-end that the middle and heel.

Do you think I need to put two pieces of tape down the full run of the spine, or build up the over-honed areas to level with the rest? I presume that once the bevel is set, I'll need to keep the tape on for the 4/8/12k, and any other future touch-ups?

The heel-first x-strokes seem like they'll help me out, although it seems the heel gets far less hone-time than the middle and toe.

-

07-07-2017, 01:25 PM #17Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

That is not unusual for the edge to be uneven in a case like this. Typically the honer does not realize that the stabilizer is keeping the heel off the stone, so just adds more pressure, causing an uneven edge.

Put the edge on a straight edge, the stone face works and see if the edge is straight, you may need to do some edge correction to straighten it.

Yes, 2 pieces of tape the full length of the spine will just about compensate for the steel that has been removed and will also prevent any more steel from being removed

Keep tape on the spine for the entire honing, change the tape after setting the bevel on the 1k and if you burn through the first layer of tape at any time. You will feel the razor get gummy, if you burn through.

When learning to hone, always use tape to protect the spine, there is no reason to needlessly grind the spine, new honers, often use too much pressure and do too many laps, setting a bevel.

The heel forward X stroke typically demonstrated, going from corner to corner, is not the stroke you want to use, especially in your case, where the heel needs more time on the stone.

If you are going to use the X stroke, keep the heel on the stone, at least half the length of the stone, then drop the toe so that it ends up in the middle of the stone at the end. But you will still have to re-shape the heel or you will just cause a heel hook. You will not be able to hone the heel unless you completely grind off the stabilizer, or simply reshape it.

-

-

07-07-2017, 01:42 PM #18Member

- Join Date

- Dec 2012

- Location

- Portsmouth, UK

- Posts

- 33

Thanked: 0

Thank you for such comprehensive replies, it is much appreciated.

I will tape the spine and take it easier on the stone; if the x-stroke is less ideal, what stroke would you recommend in my situation? I will not contemplate removal of the stabilizer, or reshaping, because I am in no way competent to give that a try.

-

07-07-2017, 02:16 PM #19FrankC

- Join Date

- May 2014

- Location

- Olympia Washington

- Posts

- 271

Thanked: 52

Reshaping a heel is really not a hard or complicated job, Marty has given you a picture to show you what the new contour NEEDS to look like. Draw this on with a Sharpie and use a small Diamond file to remove the steel by hand.

Take your time and all will be well.

With the stabilizer worked back you will then be able to get the edge on the stone, without this it's (very likely) that you will do more damage, hone a heel hook and not be happy.

-

The Following User Says Thank You to FranfC For This Useful Post:

Grenage (07-07-2017)

-

07-07-2017, 03:19 PM #20Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

It is not a big or complicated job to reshape a heel, the metal is very thin and will go quickly.

You can easily do it on a 1k, use the back side or the edge of the stone so as not to mar the face. Or a piece of 220 -400 wet and dry flat on the bench.

Just follow the post, linked in the second post. Mark the radius with a coin or large washer, and rub the heel as shown, to match the radius.

I used a diamond plate, but you can easily do it on a 1k, use the back side or the edge of the stone so as not to mar the face. Or a piece of 220 -400 wet and dry flat on the bench.

It will just take a few minutes, and if you get into restoration, this is a common problem, that can easily be repaired and should be a part of regular maintenance/ preventive honing.

Once the heel is repaired, just do a heel forward straight stroke, this will angle the stabilizer away from the stone corner and remove the steel at the edge of the heel quickly.

Then finish with X strokes, to blend the edge evenly and hone the toe. The heel of a razor is a very important part of the razor, I probably shave with the heel half of the razor 90 percent of the shave, so it is critical that the heel be honed properly and fully.

If you have an issue, post here or PM me and I will walk you through the process, it really is simple.

71Likes

71Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote