Results 31 to 40 of 48

Thread: Blade correction

-

06-30-2021, 04:48 PM #31At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,064

- Blog Entries

- 1

Thanked: 13249

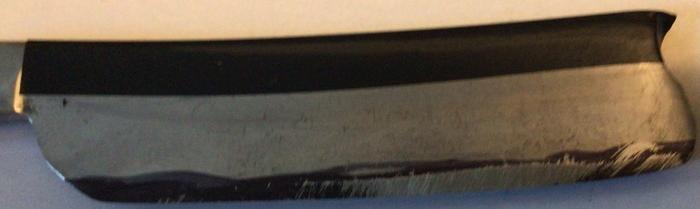

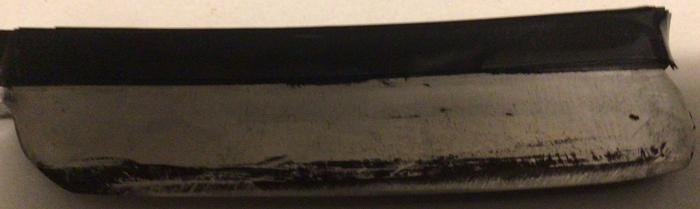

Okay first you have to be WAY more detailed in your descriptions you have the first razor that looks to need about 3 layers of tape from the pic.. You are essentially using one right now, use the Sharpie Test to see where you are at, it works

The second razor needs the heel fixed FIRST

I don't actually know what razor you are working on using the trick I gave you, I think the first

Sharpie the edge, 3 light perfect laps each side, and show me pics

Are you using one hand while honing ???"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

The Following User Says Thank You to gssixgun For This Useful Post:

Audels1 (06-30-2021)

-

06-30-2021, 06:54 PM #32

Yes I am working in the razor in the first 2 pictures marked A & B.

I am using both hands while honing.

So I am on the same page sharpie the edge/bevel then 3 light perfect laps each side. with or with out tape?

When I get back to my bench tomorrow morning will get a Picture.

Thanks for the help!!

-

06-30-2021, 10:37 PM #33

-

06-30-2021, 10:55 PM #34At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,064

- Blog Entries

- 1

Thanked: 13249

Add 3 layers of tape on top of the first correction strip, re-do the sharpie test

That is a HUGE bevel, it also means that the angle is off ie: pretty low.

Bevel size and angle are directly controlled by spine wear / edge damage a factory perfect Near wedge, to a Extra hollow all hone the same with a tiny even bevel at 16° -17°

Spine or edge damage over the years changes that,, Tape simply adds back the angle that the wear took away since welding on steel is impractical "No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

The Following User Says Thank You to gssixgun For This Useful Post:

Audels1 (06-30-2021)

-

06-30-2021, 11:26 PM #35

-

07-01-2021, 02:13 AM #36

-

07-01-2021, 11:21 AM #37

I'm probably overthinking this but, when I get vintage razors they often have hone wear.

I doubt anyone taped the spine 150 odd years ago.

What I do wonder about is how our razors will look in 150 years from now, we tape the spine so there is no spine wear. If we hone with tape for 150 years will the blade just get narrower and narrower, and the bevel angle must change a lot after honing with tape for over 100 years.

I'm not saying I don't use tape because I do (Kapton) but it's just one of the things that go through my head when I can't sleep.- - Steve

You never realize what you have until it's gone -- Toilet paper is a good example

-

07-01-2021, 12:08 PM #38

If the the bevel angle is controlled by the spine and the height if the blade and we remove steel when we hone then the bevel angle will change over time as the blade height changes.

Just you give you more to think about when you can't sleep.

So now the question is when the spine wears it narrows and the blades height shortens given all this happens evenly (we know it dose not) then the bevel angle should stay the same for a longer period of time?

-

07-01-2021, 01:58 PM #39Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

“the bevel angle must change a lot after honing with tape for over 100 years.”

No, most of my personal razors will only have a full bevel set on a 1k, once as long as I own them. Most pro honed razors have a minimum of steel removed, most I set the bevels with a 4k.

My razors get an 8k reset or low grit nagura.

The tape improved the bevel, if you want an even bevel you will need to sand and buff off the bevel then reset. All the tape did was make up for lost and uneven steel. You are not rolling enough to hone the toe and edge.

The toe will get a sharp corner and will shave fine but look funky and the heel also will get sharp it is already developing a corner. A few strokes will reprofile them. I would make it more of a smiler.

When you use tape, make sure it is on tight and flat, stretching it a bit helps. Looks like you have a couple bubbles. 3 layers can get squishy and cause wonky bevels. If it feels squishy, replace the tape. A layer of Kapton over electrical will make your tape last longer and glide easier.

Here is a good video of Charlie Lewis doing a Rolling X. Notice how the heel does not fall off the stone. Ink will tell you how much you need to roll. I use ink on almost every razor. It will save you time and steel.

Last edited by Euclid440; 07-01-2021 at 02:00 PM.

-

07-01-2021, 03:26 PM #40

62Likes

62Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote