Results 11 to 20 of 42

Thread: Honing Progress pictures

-

09-01-2010, 06:51 AM #11

So then, the scratch pattern doesn't relate to the comfort of the shave? I always thought it did...

I love to look at the scratch pattern under magnification. But, I always assumed that once the bevel was set, that magnifications on higher grit stones showed the polishing patterns of the stones and presumably weren't a representation of the sharpness of blade (sharpness quantification would be determined by observing each 10-15 strokes on the 1k to see the bevel formation develop from dull into sharpness). Either way, I love looking at the polishing patterns a stone gives, even if it is a pure aesthetics.

-

09-01-2010, 08:07 AM #12At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,152

- Blog Entries

- 1

Thanked: 13249

That is not what was asked ...

It has nothing to do with sharpness, the scratch pattern could be perfect and the edge could be 1/8 inch wide...we are just making that assumption that as those pics progress that the edge is getting sharper

Smooth and sharp are separate

I could take a Breadknifed razor and polish the bevels to perfect mirror and never get the two sides of the bevel to touch and get sharp, yet it would look great in a pic...

Or you can take a razor well into the shaving sharpness level on a 4k stone, and have it sharp, yet not smooth at all...

These are two seperate concepts that have to meet to get the "Face Factor" right...

-

-

09-01-2010, 08:12 AM #13

I didn't see anyone say that but the progressively finer scratches must meet at the edge. You can nicely polish a 500 grit shaped bevel but it won't shave so good till your polisher hits the edge & refines the previous chips & scratches.

Or... Yeah what Glen said ~ I'm so slow sometimes

Last edited by onimaru55; 09-01-2010 at 08:15 AM.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

The Following User Says Thank You to onimaru55 For This Useful Post:

Xury (09-01-2010)

-

09-01-2010, 04:55 PM #14Member

- Join Date

- Aug 2010

- Posts

- 38

Thanked: 0

What if we make the assumption that each side meets perfectly at the edge.

Then would the smoothness of the bevel make a difference in a shave?

-

09-01-2010, 05:21 PM #15At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,152

- Blog Entries

- 1

Thanked: 13249

That would be the assumption and it very well could be wrong...

Most of the natural stones leave a distinct scratch pattern on the sides of the bevel.. The Coticule and the Escher comes to mind yet they are smooth shavers.. Many of the Japanese naturals leave what is referred to as a haze finish and are considered to be very smooth to the face..

One of the cleanest looking natural stone patterns comes from the lowly CH12k...

With Man Mades it is rather easy to determine what you have from one stone to the next, the consistency is always there, the only question is whether it agrees with your face...

With naturals they are naturally inconsistent, you have to like that stone, and learn to use that stone, what everyone else's stone of the same type does, really means nothing...

So too really answer your question NO, science and rules tend to get broken down in this sport of honing SR's

Now add stropping to the equation and this gets even more fun

Last edited by gssixgun; 09-01-2010 at 05:24 PM.

-

The Following User Says Thank You to gssixgun For This Useful Post:

Scipio (09-26-2010)

-

09-01-2010, 05:25 PM #16

No. Bevel has nothing to do with sharpness of the edge.

i need to explain a little.

There is some stones will leave deeper scratches on the bevel but edge will be sharper then other stones which will have hazy bevel dull edge.hope this helps

Lets say

Norton 8 k will make bevel a lot shiny and without scratches compare to coticule.escher or 16k shapton.

But sharpness of the edge will be duller compare to any stone i mention above.

gl

-

09-01-2010, 05:27 PM #17Member

- Join Date

- Aug 2010

- Posts

- 38

Thanked: 0

You're right, I completely agree. I guess I was just originally exploring possibilities "outside the box".

However my last comment ended up adding more fuel to the fire based on the last few posts. All of that just struck up curiosity, but I didn't mean to keep driving the original question in this thread.

Sorry about that.

In the end, and I'm sure we all agree that the horse is dead...Hone, Hone and Hone....and then Hone some more.

-

09-01-2010, 05:58 PM #18

And then give the horse another kick!

Going back to the original idea of the thread, it will help YOU if YOU look at YOUR edges off YOUR hones with magnification. If you go back and forth between testing (shave test, arm hair test, whatever other test) and the scope, you'll begin to see what correlates to what. But when you switch hones, you'll have to "recalibrate" so to speak, because, as Sham mentioned, different hones give different finishes with different sharpnesses, and you cannot make assumptions across hones. But for a GIVEN hone, you can (to an extent).

All that said, you'll still have to be careful to make sure you get your bevel set, are refining the edge (not just the bevel) and using consistent lighting/magnification. Always eliminate as many variables as you can. And remember, like HNSB said above, focus on the edge first, and the scope later.

-

-

09-02-2010, 03:00 AM #19

Genco honing sequence with Naniwa and Asagi, Part I

Genco honing sequence with Naniwa and Asagi, Part I

And so I will!

Agreed here. I just bought an inexpensive hand-held USB scope that's adjustable from 10X - 150X. At 150X, the range of focus is so narrow that the scope must be touching the razor, and the light source is embedded deeply in the scope such that I can't play around with it to get "flattering" results. I was putting some shots together for a new thread, when I saw this thread already started.

The razor in the picture sequence is a Genco 5/8ths sent to me for honing that has a badly deteriorated edge due to corrosion, that is crumbling. But I decided to use it to show the effects of my usual honing sequence on the bevel surface.

The magnification is 150X, the size of the area shown is less than 1/8" across. I used a sharpie to mark the razor as a reference point at the left edge of the photos. I had to refresh the sharpie mark a few times, but I did my best to keep the reference area, angle, and lighting as consistent as I could with my skill level and an inexpensive scope.

Here's the sequence:

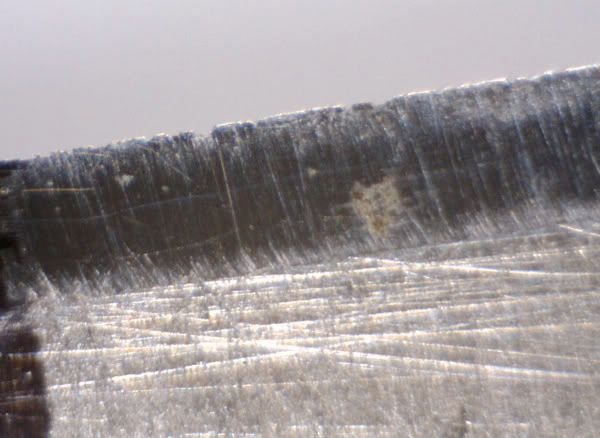

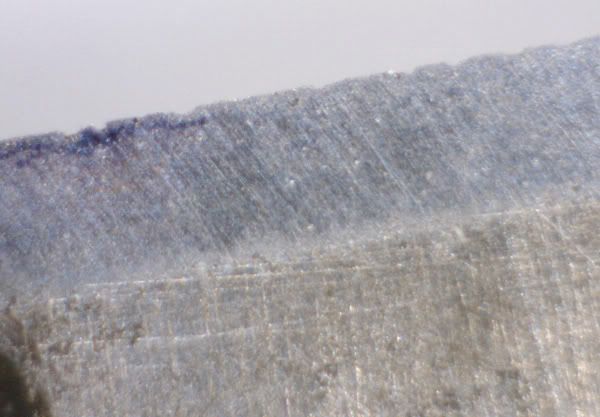

Photo 1: Genco razor as I got it, pretty well polished, but with a crumbling edge:

Photo 2: Same spot, after bevel reset using Naniwa 1K. I used 50 circular strokes on each side, followed by 20 X-strokes

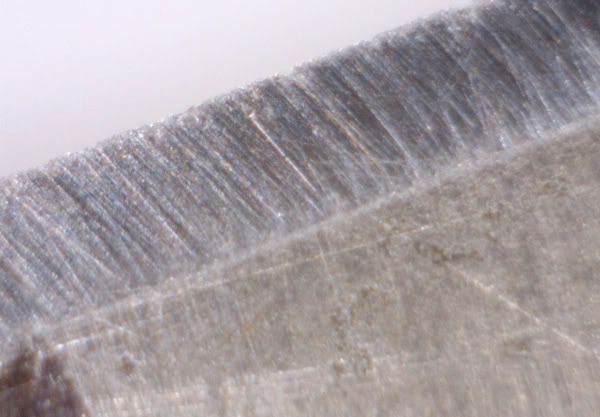

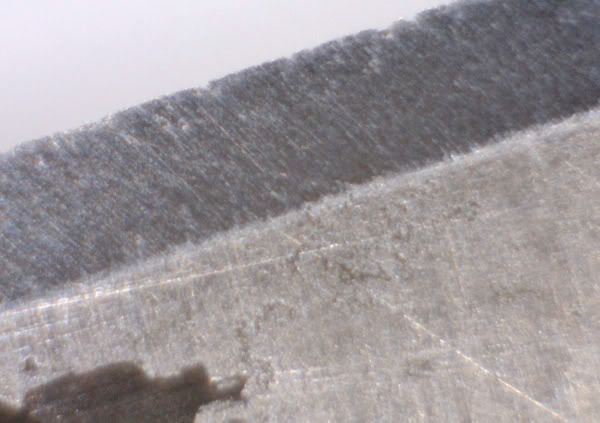

Photo 3: Same spot, after Naniwa 5K. I used 50 circular strokes on each side, followed by 20 X-strokes

Photo 4: Same spot, after jumping to a Japanese Asagi with heavy slurry. This was the result of about 30 - 40 X-strokes.

The Asagi with heavy slurry really removed the bevel scratches and replaced them with the typical "hazy" finish of fine scratches, but the crumbling edge is still present.

I'll post the rest of the photos next...Last edited by FatboySlim; 09-02-2010 at 03:17 AM. Reason: Embedded URL link to the scope I used

-

-

09-02-2010, 03:10 AM #20

Genco honing sequence with Naniwa and Asagi, Part II

Genco honing sequence with Naniwa and Asagi, Part II

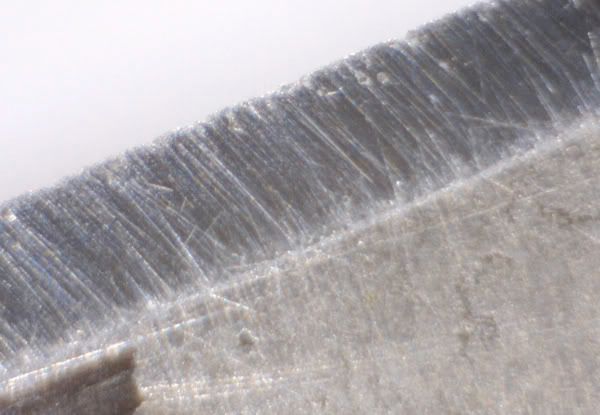

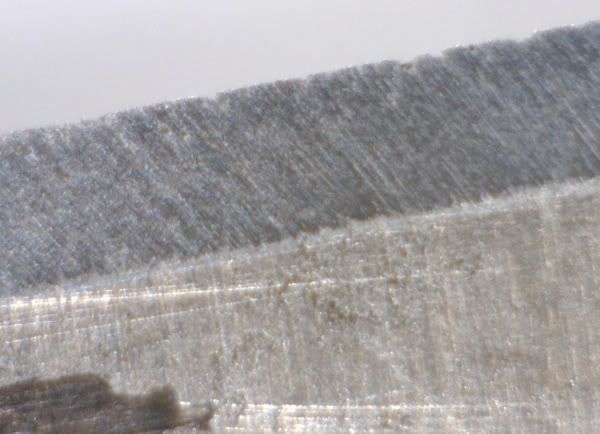

Photo 5: Same spot, followed by about 20 - 30 more strokes with a medium-diluted slurry. (The black area right on the edge is an accidental smudge from the sharpie when I was refreshing my reference mark. It was made after the strokes with medium slurry, which had caused a lot of the reference mark to get wiped away.)

Photo 6: Same spot, after 20 - 30 more strokes on the Asagi with a light/diluted slurry

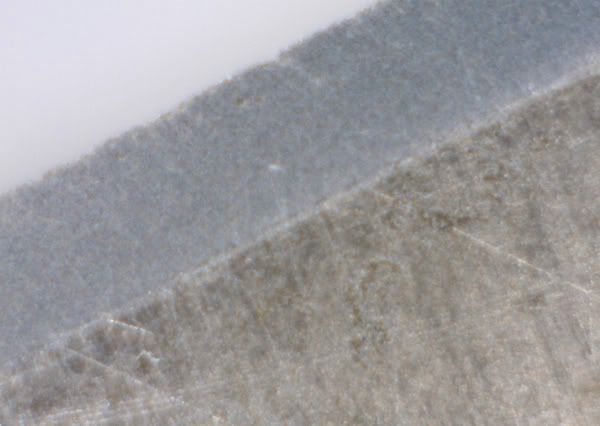

Photo 7: Same spot, after about 25 more strokes on the Asagi with water only.

Photo 8: Same spot, after stropping 70 strokes on an SRD Bridle strop

In the end, the razor is fairly sharp, but the edge has deterioration issues that keep it from having the integrity to take and hold a really keen edge. But just for showing the effect of different stones and slurry thicknesses on bevel polishing, it was fun and worthwhile to do.

-

The Following User Says Thank You to FatboySlim For This Useful Post:

Scipio (09-26-2010)

5Likes

5Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote