Results 31 to 40 of 51

-

04-12-2013, 12:31 PM #31

Any more on info on the SEMs?

Hur Svenska stålet biter kom låt oss pröfva på.

-

04-12-2013, 01:09 PM #32member emeritus

- Join Date

- Dec 2012

- Posts

- 112

Thanked: 62

-

-

04-12-2013, 04:05 PM #33Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

To polish the edge we must polish the bevel, even with a micro bevel. When we polish with stones, oxides, paper or leather we are polishing, burnishing the edge to straighten and smooth it. Paste and stropping are just extensions of what we do with a progression of finer or slurred stones.

You may not agree with what, a photo depicts, but you can’t argue with the shave.

Do what works for you.

-

04-12-2013, 08:01 PM #34

No razor I hone will pass the HHT with my fine hair straight off of the hone.

A proper strop and it all changes, for testing post hone I do 20/50 and then they pass the HHT.

I can do this at the 5k stone, then if i do a lap or two on the 8k it wont pass the HHT until I strop agian.

More than enough proof for me, I strop every time.

-

04-14-2013, 07:15 PM #35Junior Member

- Join Date

- Mar 2013

- Location

- Bulls Gap TN

- Posts

- 5

Thanked: 0

There's also the idea that stropping will remove fine particles from the blade, as well as any residue from honing oils or possibly even soaps. It may not really have any abrasive qualities, but the idea of really cleaning the blade is a good enough reason for me.

-

04-15-2013, 04:29 PM #36Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 7,974

- Blog Entries

- 1

Thanked: 2204

That paper is well intentioned but completely misses the mark when it comes to straight razors.

Not one portion of that paper is focused on how well a razor shaves.

The professor did not do his homework before he structured his tests.Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

04-20-2013, 02:58 PM #37member emeritus

- Join Date

- Dec 2012

- Posts

- 112

Thanked: 62

-

The Following User Says Thank You to fuzzychops For This Useful Post:

Lemur (04-20-2013)

-

04-20-2013, 03:08 PM #38

I for one would like to see SEMs for an edge that has been well sharpened and found to shave well but is to harsh on the skin

and then the same edge stropped until it shaves well but now feels smooth.Hur Svenska stålet biter kom låt oss pröfva på.

-

04-20-2013, 03:14 PM #39At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,961

- Blog Entries

- 1

Thanked: 13226

-

04-20-2013, 03:17 PM #40

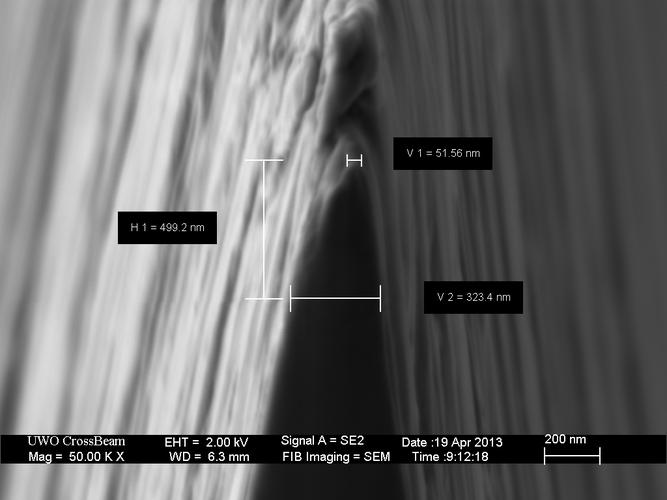

gssixgin; That's how I read it too and it really supriced me, isn't the known "truth" that it's hard to ever get a steel edge radius under .5 micron?

Hur Svenska stålet biter kom låt oss pröfva på.

73Likes

73Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote