Results 41 to 50 of 51

-

04-20-2013, 03:23 PM #41At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,026

- Blog Entries

- 1

Thanked: 13245

I guess the best test is to measure a Gillette DE blade and see what you get

Verhoeven was calling a Gillette DE at .32 +/- microns page 41/55 in that report, so I guess that would be the place to start, that would take the variable of honing out of the equation...

If those are all correct assumtions then my view of honing just jumped into a whole other realm I found it hard that we argue over 1/100th's of a micron differences in finishers, I can't imagine a 1/1000th difference

Last edited by gssixgun; 04-20-2013 at 03:31 PM.

-

04-20-2013, 03:44 PM #42member emeritus

- Join Date

- Dec 2012

- Posts

- 112

Thanked: 62

Thanks Glen,

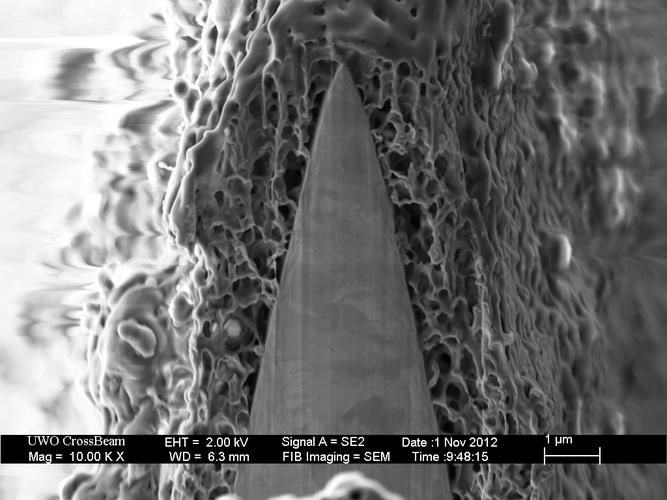

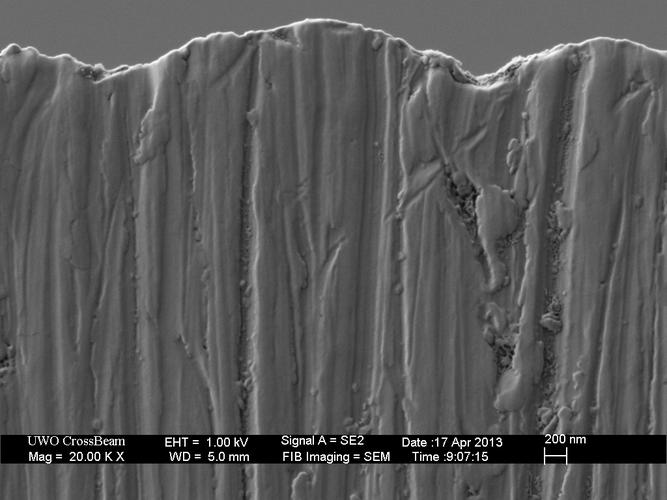

The image above is from a blade honed on 3 micron lapping paper, then stropped on clean leather. The edge width is between 0.05 and 0.1 microns (or 50 to 100 nanometers)

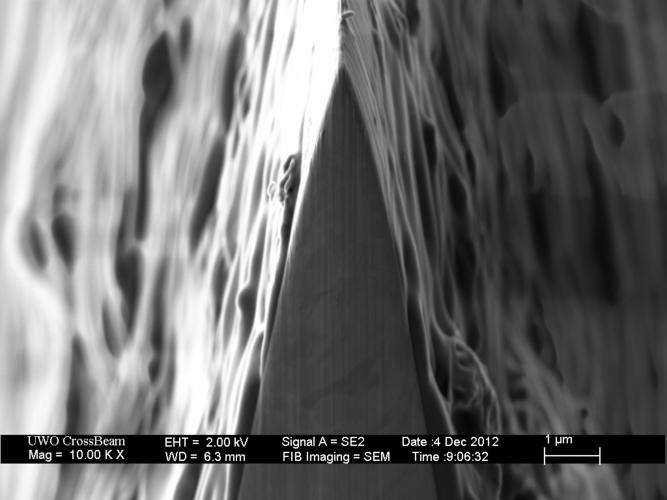

Here is a Feather DE blade (edge width around 50 nanometers)

A Kai blade (edge width 50-100 nanometers)

Even the lowly Derby blade is around 100 nanometers

Of course, width (or apex radius) is only one aspect of the edge. Todd.

-

The Following User Says Thank You to fuzzychops For This Useful Post:

RazorforLife (07-22-2013)

-

04-20-2013, 03:57 PM #43At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,026

- Blog Entries

- 1

Thanked: 13245

I guess if I were you, I would be forwarding this stuff to Verhoeven and asking the million dollar question ....

Waz Up ?????

The math seemed to work out with the sizes he presented when compared to the honing grits used to get there, now things become very blurry again, using .50 Micron grits to achieve .05 micron changes makes things a bit odd and that is at one of the best case scenarios...

and that is at one of the best case scenarios...

Well heck I do remember somebody saying "Honing ain't rocket science"

Well heck I do remember somebody saying "Honing ain't rocket science"

Last edited by gssixgun; 04-20-2013 at 03:59 PM.

-

04-20-2013, 05:29 PM #44member emeritus

- Join Date

- Dec 2012

- Posts

- 112

Thanked: 62

I think it is important to understand that grit size and scratch size differ by at least an order of magnitude.

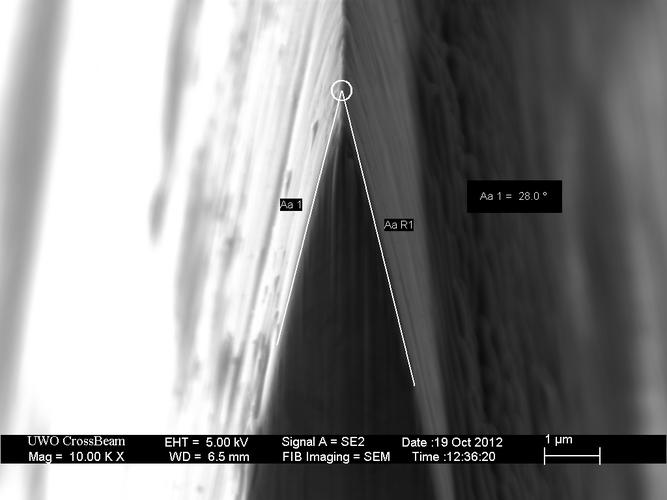

Here is the edge immediately after honing on 3micron diamond film:

The scratches are about 0.2 micron wide and less than 0.1 micron deep.

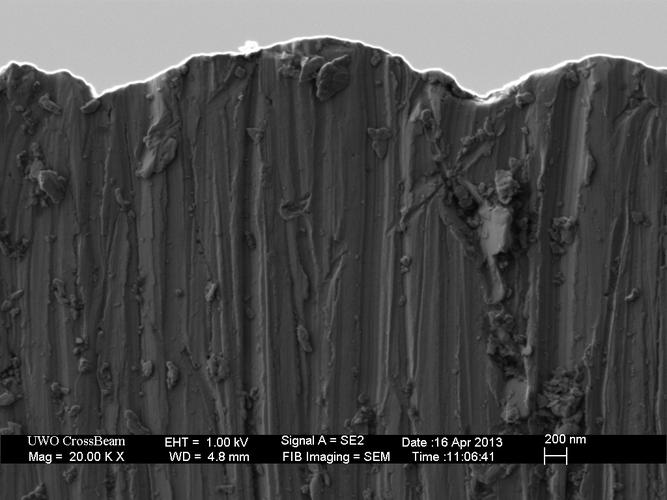

... just to stay on topic, here is the same spot after 100 laps on clean leather:

Last edited by fuzzychops; 04-20-2013 at 05:45 PM. Reason: added image

-

The Following User Says Thank You to fuzzychops For This Useful Post:

RazorforLife (07-22-2013)

-

04-20-2013, 06:05 PM #45At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,026

- Blog Entries

- 1

Thanked: 13245

Have you tried to contact Verhoeven with your findings???

I don't know what your thoughts are, but if I were in your shoes I would be thinking of publishing a paper, to show your findings...Last edited by gssixgun; 04-20-2013 at 06:10 PM.

-

04-20-2013, 06:46 PM #46member emeritus

- Join Date

- Dec 2012

- Posts

- 112

Thanked: 62

-

04-20-2013, 07:02 PM #47At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,026

- Blog Entries

- 1

Thanked: 13245

John Verhoeven

There is his contact info I would start there and at least send him your findings, I bet the University has more contact info for him if you were to ask..

Basically what I am saying is you are calling his findings into question, so I would assume you would want to ask him why your findings are at a different magnitude then his... Perhaps there is something more there

Last edited by gssixgun; 04-20-2013 at 07:05 PM.

-

The Following User Says Thank You to gssixgun For This Useful Post:

fuzzychops (04-20-2013)

-

04-21-2013, 04:37 PM #48member emeritus

- Join Date

- Dec 2012

- Posts

- 112

Thanked: 62

There is a reference in the Verhoeven manuscript:

[4] J.F. Sackman, A Close Shave, Physics in Technology, vol. 9, 208-213(1978)

This paper describes the manufacture of DE blades and contains the following:

The truth was out there.The tip radius is measured absolutely by reflection or scanning electron microscopy. Generally it is about 50 nm.

-

04-21-2013, 04:59 PM #49

That's why you SEM pics supriced me, I don't doubt that you got the measurement right, I just find it intriguing that your edge is so much finer.

It could be that the .5 micron is derived from industrial sharpening, but then I don't even know their definition for an edge or how to take the measurement.

Keep 'em SEMs coming!Hur Svenska stålet biter kom låt oss pröfva på.

-

04-21-2013, 06:11 PM #50

Interesting, the original site is blocked by my Webb provider for Security reasons!! So. It must be incorrect and Stropping is Good for you! Or it has something to do with Leather!

73Likes

73Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote