Results 171 to 177 of 177

-

11-09-2020, 02:33 AM #171Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Exactly, from the crack back is short grain. Every time the axe bites wood, the back of the eye bites into the back of the handle where the crack is, the shortest grain and will eventually break off and the crack may run in towards the middle of the handle.

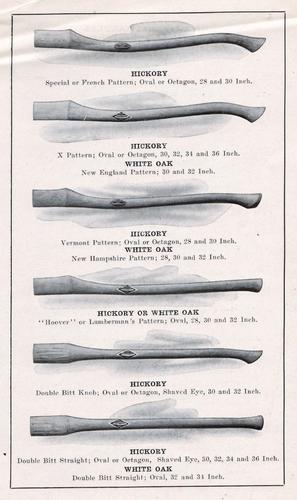

This can be avoided and almost get the same/ similar curve to the handle by moving the curve forward and making the shoulder straighter as in the first two shoulders in the photo. The top one has more of a pointed shoulder, the second one from the top has a much straighter/ stronger shoulder. You can also hang the head higher, so it bottoms out higher on the shoulder.

Last edited by Euclid440; 11-09-2020 at 02:42 AM.

-

11-09-2020, 10:31 PM #172

In the axe shown here the grain is at about a 45' angle to the head and there I can see it being "shorter".

In Harry's axe the grain is what I would call verticle and I cannot see where the peak is weaker.

You could put the peak slightly back from the head and it would be decorative but have no influence on a crack that I can see.

-

11-09-2020, 11:13 PM #173

-

The Following User Says Thank You to Grizzley1 For This Useful Post:

HARRYWALLY (11-10-2020)

-

11-09-2020, 11:33 PM #174

Always a fun time with my 4 nephews

-

11-09-2020, 11:38 PM #175

A wicked ...long lasting edge on this one...Been 3 camping seasons..yet to sharpen it

-

11-09-2020, 11:57 PM #176Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,812

Thanked: 562

-

11-10-2020, 05:49 PM #177Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

The other thing that can cause a failure is improper fit of the wedge to the kerf and eye, quite common. The wedge taper must match the eye and fill all the empty space, (the kerf and any space between the top of the handle and sides of the eye).

Measure the eye width and length, from the bottom and the top. The handle and the wedge, must match the measurements with the wedge installed out of the eye plus a little extra to compress the wood enough to fill the eye tightly at the base of the eye and middle and slightly mushroom the top of the head.

Any empty space or gap is an area ripe for failure. As are crushed wood fibers from forcing an improperly fitted/tapered or too large wedge to the kerf.

It takes just a few minutes to take some measurements from the eye and the handle with the wedge installed and fit the handle and wedge to the eye.

I restore and sell old tools, and buy a lot of hammers, hatchets, and axes. Most of what I buy are broken handle, discarded tools. The cause of failure is often an improperly fitted wedge.

312Likes

312Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote