Results 41 to 50 of 57

Thread: Hard to walk away from.

-

07-20-2016, 03:01 PM #41

The blade cost me less than $40.00. I had the scales and hardware replaced and am still happy with the amount paid.

-

The Following User Says Thank You to Mrchick For This Useful Post:

Glock27 (07-20-2016)

-

07-20-2016, 04:06 PM #42

If I remember correctly, they only have 2 buffer models. One of them I believe had a different type of wheel on one end, like a wire brush or similar which I did not want. I got the one that has buffing wheels on each end. You can mount it on a bench or you can buy a pedestal mount for it. I wanted more bench room so I got the pedestal. I have used the white rouge for a final polish. Also, don't use a Dremel unless you have practiced on a junk blade for quite a bit. Don't just jump in & start using one because you can damage a good blade in just a nanosecond. You have to be aware of which way the tool is spinning & never use it with it spinning against the edge. I got Lynn's dvd back when I first joined & he shows how he uses a Dremel & I think he even says to be very careful with it if using one. I also use electrical tape on the shank & collet just in case it touches the blade. I use one only if I can't polish it out by hand first. I prefer not using one if I don't have to. Using any tool that can do damage increases the risk of doing damage so always try your other options first.

-

07-20-2016, 05:43 PM #43Glock27

- Join Date

- May 2016

- Location

- Michigan

- Posts

- 316

Thanked: 18

And when to fold them...he-he-he!

-

07-20-2016, 05:56 PM #44Glock27

- Join Date

- May 2016

- Location

- Michigan

- Posts

- 316

Thanked: 18

Thanks engine46. I just searched Harbor Freight and found two. Both operate at 3460 RPM, quiet fast, fast enough to create burn spots on a blade. I guess once you do that the blade is tossable. I could not locate a speed controller for electric motors at Harbor Freight so it is not likely that I will go that route as I have two double shafted motors that operate at 3200 RPM and one at 3400 RPM, both still far too fast. Now I am speaking out of the side of my mouth and I don't mean to stick my nose into your butter, but exactly how do you accomplish polishing away defects as stain and light pitting on a buffer that flies that fast. I would be interested. I am having a tough time imagining how to hold the blade while it is flying so fast (yes I know, I don't place the cutting edge against the rotation of the buffing wheel).

One small difficulty I face is shaky hand, good for dousing salt and pepper, but I can see a steady hand would be required and the lightest possible touch. Would you elaborate a bit and elucidate my geriatric mind please.

-

07-20-2016, 06:15 PM #45

What's no to be very pleased with its absolutely gorgeous! Congrats to you!

-

-

07-20-2016, 09:32 PM #46Glock27

- Join Date

- May 2016

- Location

- Michigan

- Posts

- 316

Thanked: 18

Great. Excellent value. Wish I could be so lucky.

-

07-20-2016, 10:18 PM #47

-

07-21-2016, 12:08 AM #48Member

- Join Date

- Nov 2013

- Posts

- 54

Thanked: 8

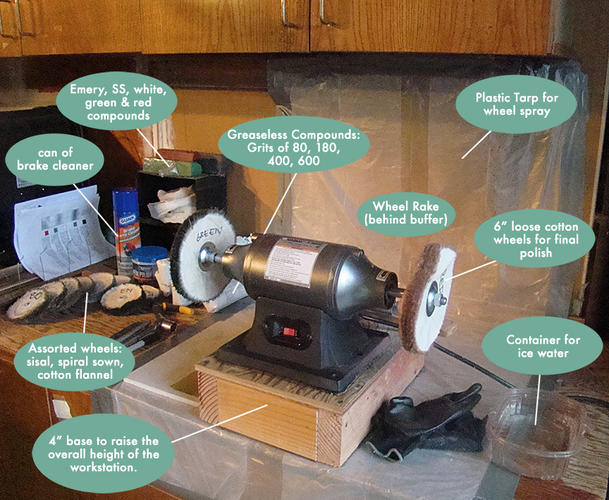

Harbor Freight Central Machinery #94393. Reg $45, but they go on sale and with coupons you can snag one for under $30. Decent buffer. FAST, yes so you do have to monitor heat levels. I have three of them in the shop and they've held up fairly well with regular use. One I had to replace right out of the box due to a faulty motor, but once replaced, it's worked like a charm. Here's a photo of my initial set up before adding a few more buffers along the line.

-

The Following User Says Thank You to Kevin78 For This Useful Post:

Glock27 (07-24-2016)

-

07-24-2016, 12:18 PM #49

What an awesome find the blade is beautiful

-

The Following User Says Thank You to azourital For This Useful Post:

Mrchick (07-24-2016)

-

07-24-2016, 12:24 PM #50

That razor came out fantastic, congratulations.

-

The Following User Says Thank You to hrfdez For This Useful Post:

Mrchick (07-24-2016)

92Likes

92Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote