Results 11 to 19 of 19

-

09-06-2020, 05:11 PM #11Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Yes, sorry for the confusion. I should have made that two separate line items.

Grind: Near wedge. I'm going to be grinding it with a contact wheel so it will have a bit of an arc to it (not completely flat). My goal with this is to replicate a large stone wheel grinder.

Thickness: Thick enough that it could be honed laying flat with two or three layers of tape. I don't want it so thin that I am trying to "free hand" the angle.

-

09-06-2020, 05:25 PM #12Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

I've been perusing the stub tail pictures. This grind is kind of appealing to me. It doesn't go all the way back to the spine, which would allow for a thinner piece of steel.

-

09-06-2020, 05:37 PM #13Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,325

Thanked: 3228

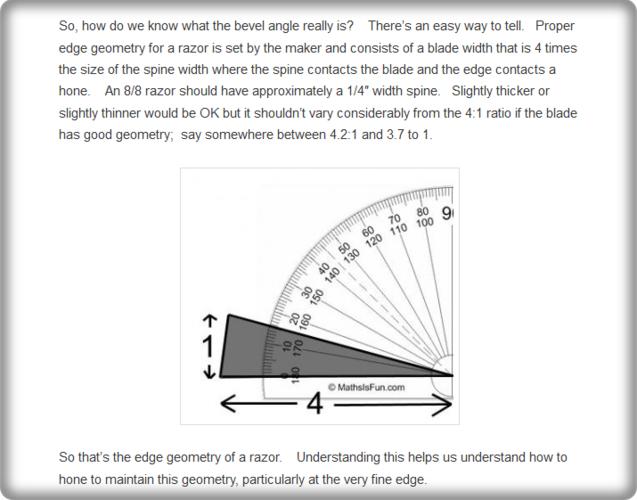

Yes, you are describing a near wedge and not a true wedge of which there are very few. When I said size it is the same as width of a razor measured from where the spine contacts the hone to the apex of the edge. You shouldn't have to free hand the angle if you go with what Bruno told you a few years ago about width to thickness ratios. The geometry to get near a 17 degree bevel angle should be the same for a near wedge as for a full hollow, the widths being the same for both, only you remove less steel from the blade in making a near wedge. The bevels might possibly be wider on the near wedge.

https://sharprazorpalace.com/honing/...vel-angle.html

BobLife is a terminal illness in the end

-

09-06-2020, 05:39 PM #14Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

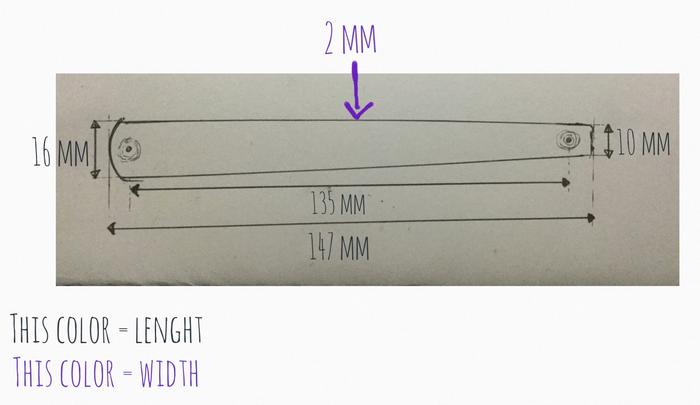

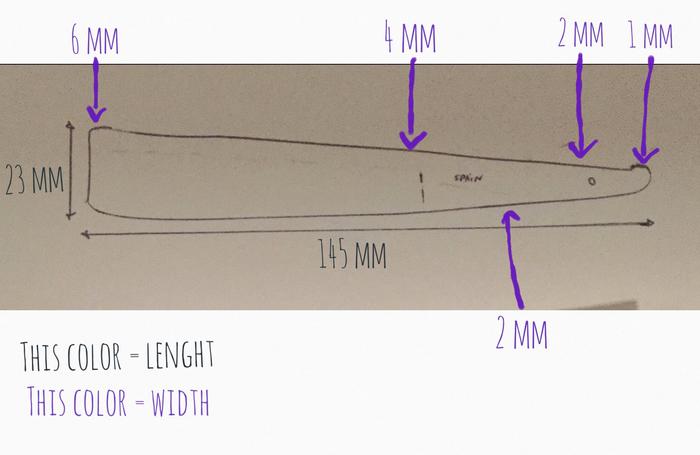

From another thread on this forum. I'm placing them here as reference for this project.

-

09-06-2020, 05:49 PM #15

I don't think toxicity would be much of an issue in the wedge. Maybe more so in the making of it, though. Definitely cut, file, grind, or sand with proper PPE including gloves. Same for melting/casting.

Sounds like an interesting project, and a good one to use your spring for. Looking forward to seeing it.

-

09-06-2020, 05:54 PM #16Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,325

Thanked: 3228

OK, now you are talking a razor with a tapering width blade so the spine thickness varies to accommodate the varying widths of the blade is all. The old way of measuring blade width was not from the top of the spine but from where the spine contacts the hone. That might make a difference when calculating. What is above that contact point is irrelevant to the geometry calculation.

Bob

BobLife is a terminal illness in the end

-

09-06-2020, 06:36 PM #17Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

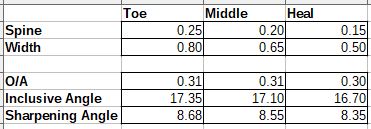

Correct. I measure where the hone contacts the spine, not the top of the spine. Tapering the thickness of the spine from the toe to the tail would allow for a varied blade width and still maintain the proper edge bevel. The more I look at these, the more appreciation I have for them. They may look "plain", but a lot of thought went into these things.

-

09-06-2020, 07:21 PM #18

I think this is a better explanation.

“Wherever you’re going never take an idiot with you, you can always find one when you get there.”

“Wherever you’re going never take an idiot with you, you can always find one when you get there.”

-

09-07-2020, 12:01 AM #19Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

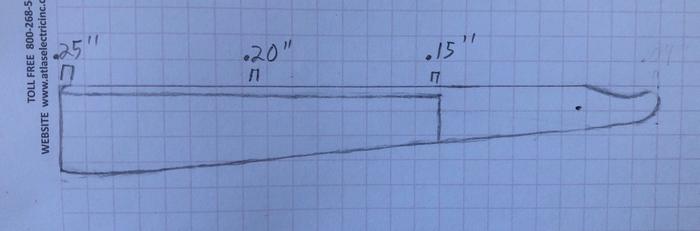

Based on the numbers and the drawing from post #14, I did some quick math and made a (fairly) to scale sketch. It looks like starting with a .25" thick spine at the toe, and tapering back to a .15" spine at the heel would indeed keep a proper bevel angle for that shape of blade. It would also give you a little bit of a "flat" or "unground" spot on the side of the blade near the spine. With that, I'm pretty confident that I could make one that would actually shave. One of the members here has been VERY gracious and is lending me one to look at. Once I get that in hand and actually see one in person, I may have to re-think everything.

15Likes

15Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote