Results 1 to 10 of 19

Threaded View

-

09-06-2020, 03:40 PM #5Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

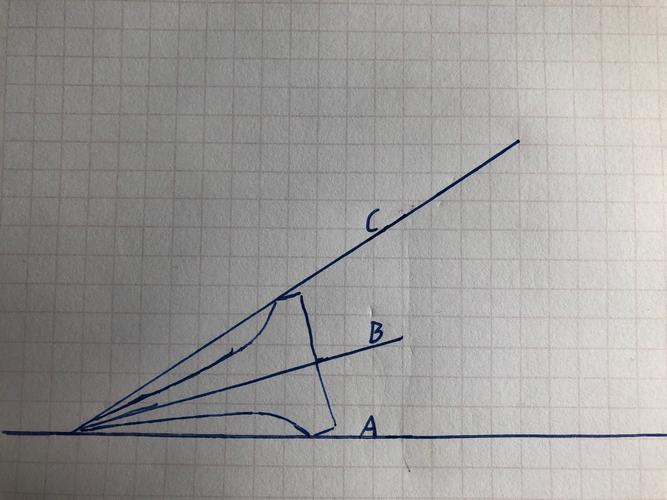

Thanked: 59 I think that you are referring to this.Wow. 3:1 would make for a really fat razor. Very obtuse bevel angle. But be careful of oversimplification here. The ratio between overall width and spine thickness is not the thing. The ratio of spine thickness to the distance between the edge and the highest point of the spine's contact area (call that distance, "H") is the true determination of bevel angle. Taking half the spine thickness and dividing it by H and you have the sine of half the bevel angle. Find the angle and double it, and there is your bevel angle.

I think that you are referring to this.Wow. 3:1 would make for a really fat razor. Very obtuse bevel angle. But be careful of oversimplification here. The ratio between overall width and spine thickness is not the thing. The ratio of spine thickness to the distance between the edge and the highest point of the spine's contact area (call that distance, "H") is the true determination of bevel angle. Taking half the spine thickness and dividing it by H and you have the sine of half the bevel angle. Find the angle and double it, and there is your bevel angle.

https://sharprazorpalace.com/honing/...ml#post1913223

and this, as example.

Yes, I do measure from the edge to the point where the spine contacts the hone, not the back of the blade. A 3/1 ratio would put you at an 18 degree angle (1 divided by 3 = 0.3333 and Tangent of .32492 = 18 degrees). A 4/1 ratio would put you at a 14 degree angle (1 divided by 4 - 0.25 and Tangent of 0.24933 = 14 degrees). So that is the range that I shoot for when making a razor. Plus or minus tape can fine tune the angle from there.

You are correct that razors of that era are almost all a wedge or a near wedge. The machine that makes the nice hollow grinds that we are familiar with wasn't invented yet.

Thanks for the information on your experience with the thin razors. I have never made a replica of a 1700's razor, but it would be fun to do. So I am just trying to get an idea on how thick to make it.

15Likes

15Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote