Results 11 to 20 of 29

Thread: Project. My first horn scales

-

12-30-2016, 11:44 AM #11

Scales look great and I think this will look real good when finished.

No help on the razor though, will be here watchingLook sharp and smell nice for the ladies.~~~Benz

Imperfection is beauty, madness is genius and it's better to be absolutely ridiculous than absolutely boring ― Marilyn Monroe

-

12-30-2016, 12:00 PM #12

If this are some of your first you're doing great!

-

12-30-2016, 01:56 PM #13

Awesome work on the scales. I love horn scales.

We have no control of what other people do or say to us, but we have control to how we REACT !! GOD BLESS

-

12-30-2016, 01:59 PM #14

-

12-30-2016, 04:24 PM #15Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Nice work on the scales. It is surprisingly easy to reverse a pattern on a set of book matched scales. Mark the insides of each scale before cutting, then glue them together and shape.

Make sure of the orientation before you cut.

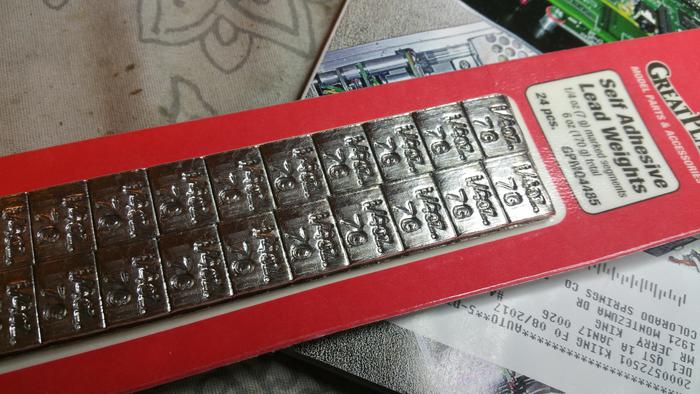

Lead is the traditional spacer material for horn scales. You can buy 1/8-inch lead from hobby stores, for sail plane weights. Glue onto a stick with double sided tape or one of the scales and shape on sandpaper. Just takes a few minutes.

You should re-shape that heel before you put it on the scales. The Stabilizer is probably responsible for the heel hone ware and the uneven edge.

Bring the edge corner forward of the stabilizer.

-

12-30-2016, 04:48 PM #16

-

12-30-2016, 05:29 PM #17

I hadnt noticed that. Thanks for pointing it out. I got some stones comming in the mail so ill wait till i get them then work on the heal next weekend. Its just a little amount that i see should come off. Might post up a pic of my heal fix idea.

Guess ill get some lwad for the wedge and try again. Looks like this project will be longer than i thought. Thats ok. Ill post up what i got now mocked up with mucro fasteners. But finished will be a while. Now i can start on another. Cool.

Thanks all for the input and propson the horn.Last edited by Gasman; 12-30-2016 at 05:32 PM.

It's just Sharpening, right?

Jerry...

-

12-30-2016, 06:51 PM #18

These were the weights I was able to find at the hobby store. Just barely big enough. If I could melt them of flatten them just a little would be better. Guess I'll see how it comes out.

And here is what I'm thinking on the heal of the razor...

Getting rid of all the red ink. Well, maybe just a little less at the edge.It's just Sharpening, right?

Jerry...

-

12-30-2016, 07:23 PM #19

I make lead wedges out of pure lead round balls that are used for black powder shooting. I flatten and taper them by hammering and then finish on sandpaper. Keep the sandpaper wet to minimize airborne lead particles.

"Every normal man must be tempted at times to spit on his hands, hoist the black flag, and begin to slit throats." -H. L. Mencken

-

12-30-2016, 07:45 PM #20

89Likes

89Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote