Results 131 to 140 of 141

Thread: Tapered blades.

-

07-16-2021, 08:37 AM #131

I'll add my 2 cents

The key to making Trizact belts last is using next to no pressure.

Buffing is another enjoyable rabbit hole, there are so many variables ,mops,compounds,techniques, i think there is more to it than grinding.

-

07-16-2021, 02:25 PM #132

Iím not sure yet. Those belts are still going. They last a long time, especially since youíre polishing and not trying to hog off material. The finish looks very modern though, not like a crocus or glaze on a Sheffield.

I think thp001 has a lot more experience with those belts than I do, sounds like. The cost is outweighed by the life so far for me. The finish is nice but looks in no way like a vintage finish.

-

07-16-2021, 05:56 PM #133Senior Member

- Join Date

- Jul 2020

- Posts

- 270

Thanked: 44

I know what you mean about the finish, for a while I was just not happy with my razors and I couldn't figure out why. I would look at the scratches under a loupe and compare them to some razors I have and they seemed of a similar fineness. I think what it is is that the belt cuts scratches which travel further across the blade faces where as the scratches on older razors are shorter, possibly from using smaller wheels than those used to create the initial grind although I can't be certain of the wheel sizes they used after initial grinding and into the glazing/polishing. From videos I have seen of old pocket knife making in Sheffield (they take the blades to a crocus finish) the wheels are all similar sizes, apparent in the video is that the wheel speed seems to decrease closer to finishing. I've found the cork belts get closest to a glaze finish (although still different from vintage), followed by non-woven abrasives but I moved away from those as they tend to round surfaces.

I never bother trying to imitate a crocus finish, there are some amazing restorations out there which are very high gloss but they just don't look the same; my own experimentation with polishing has been unsatisfactory so all my blades are in a glaze finish but I will polish spines since on a rounded surface buffing looks the same. It's that super flat mirror on the blade faces and tangs and the crisp lines, on a true crocus finish, that can only be made on a lead lap imo. I'd love to get a motor and make up some glazing wheels and a lead lap and do some experimenting but don't have much space in the shop at the moment.

AFAIK, back in the mid 19th century razor trade when all cutlery, not just razors, was purely hand ground, there were 4 main steps. Grinding, rough glazing, fine glazing then polishing. The hulls were set up three men deep for all the grinding and glazing, polishing was often done in a separate area away from the coarse grinding dust which filled the air which could ruin the polish. I can't imagine trying to polish a blade using only a 4 grit progression. Men's time was cheap and short lived back then however.

Yes hardly any pressure, especially in the finer grades as you'll just end up burning your work. On any belt or wheel you should let the abrasive do the work but it's especially true on Trizact.Last edited by thp001; 07-16-2021 at 06:17 PM. Reason: additional content

-

07-17-2021, 10:09 AM #134

It does sound obvious, less pressure equals longer life..

Having spoken to some experts Max & SAIC abrasives, I learnt that pressure on an A45 400 grit Trizact will give you one or two good cuts then the belt will not cut the same.. Extremely light pressure and they seem to just keep going for an age.. Worth the extra cost but not necessary in my case.. 400 or 600 grit Aluminium Oxide then Emery sisal and onwards..

This is a tapered blade thread. Apologies :/

-

07-17-2021, 07:00 PM #135Senior Member

- Join Date

- Jul 2020

- Posts

- 270

Thanked: 44

-

07-17-2021, 07:08 PM #136

Hello my friend! Wow it was great to see your post...and nice to be remembered. I know about 'wormholes' for sure and for certain! Had some health challenges the last couple of years (all better now!), but now most of my time is spent as the care giver for my 95 year old Mother and a 65 year old mentally challenged brother with severe memory functions. It's quite a challenge for me as I'm no longer a "spring chicken" myself, but it is also rewarding for me to be able to to fulfill this responsibility for my family.

Wish I could spend a lot more time here on SRP but sadly I am only able to check in once in a while, let alone restore the many, many razors I have in need of work. I do think of the many fine folks here on SRP and especially my close friends like you and Tom S. and others. I think of you all very often at rare quiet times at night.

Take care ...all of you. See you soon.

BTW...Phrank...remember the beauty W&B Tapered blade I have? Actually just shaved with it 2 weeks ago. Thought of you the whole time i was shaving with it! Lupus Cohors - Appellant Mors !

Lupus Cohors - Appellant Mors !

-

07-19-2021, 08:06 PM #137Senior Member

- Join Date

- Jul 2020

- Posts

- 270

Thanked: 44

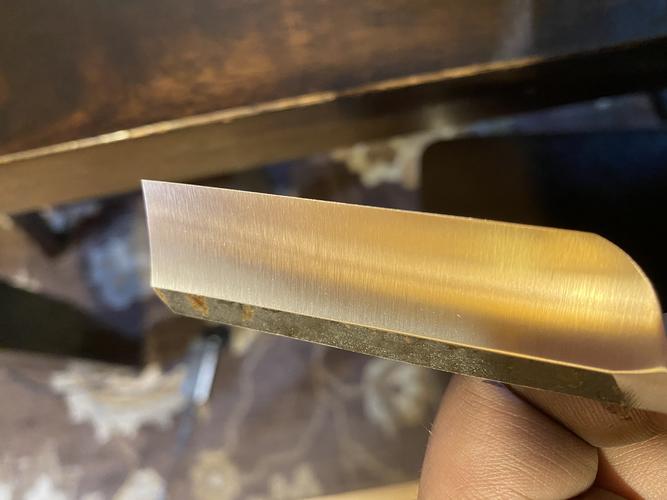

To hopefully only add one final diversionary post, I was thinking about the look of the old glazed finish and that of modern belts and decided to undertake a little experiment. I had a razor blank that needed grinding up so I took it all the way to the 5 micron and then down to the 800 grit cork like on a previous blade I made, but this time when I went to the cork, instead of using a contact wheel the same diameter as the hollow, I went to a smaller wheel, from a 4 inch wheel to 2 inches. This meant I had to pass side to side and traverse down the face of the blade. My theory was that the old glazed finish looked the way it did because the scratches from the abrasive didn't travel from the spine to the edge but were shorter, overlapping strokes possibly from a smaller wheel. I got a similar effect from this experiment on the cork belt, hopefully you can see from the following pictures:

Original 800 Grit Glaze (Wheel same size as grind, in this instance 10 inches diameter)

Small wheel 800 Grit Glaze (4 inch wheel initial grinding, 2 inch wheel glazing)

Side by side

Crop in for detail

Last edited by thp001; 07-19-2021 at 11:06 PM.

-

12-09-2021, 03:36 PM #138Junior Member

- Join Date

- Dec 2021

- Location

- Pennsylvania, USA

- Posts

- 2

Thanked: 0

Long time lurker... first post.

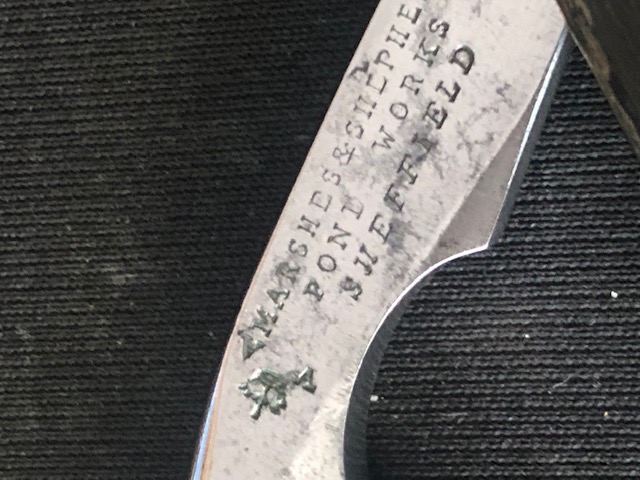

I just acquired this Marshes and Shepherd which seems visually similar to many razors pictured previously in this forum. While the blade tapers from ~ 13/16" down to ~ 11/16" I was not able to see or measure any difference in the width of the spine. From everything I can tell it seems to fit all of the signatures of this style of razor minus the spine tapering (and likely not a result of hone wear). Can anyone chime in on how much spine taper is typical?

The other interesting feature is that the Crown stamp appears to be 'VA' opposed to 'VR'. I am assuming that this must refer to Victoria and Albert opposed to Victoria's Reign which would probably date it after 1840. This is the first I have seen a 'VA' stamp and am a bit curious about how common it was relative to the 'VR' stamp.

Any insight on this razor would be appreciated! (Am enjoying trying to piece together any history I can).

-

12-09-2021, 10:29 PM #139

Welcome to the forum

If you don't care where you are, you are not lost.

-

12-10-2021, 03:32 PM #140

This is indeed the most interesting thing to me and what popped out at me first. I have never seen VA before and was also assuming that it was Victoria and Albert, but not sure. If so I would assume it was done to commemorate the specific year, probably the marriage. A very fascinating mark..

As to the spine width, it's not a hard rule that it should decrease exactly proportionally to blade width. I think as long as it held a functional edge it was fine. Yours likely would have had (or maybe still has traces of) the etching "An Excellent Razor" near the spine. I can see something there - is it legible or can you get a better pic of the etching? This also rules out any kind of wear since it would have been original on the blade face.

343Likes

343Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote