Results 1 to 10 of 28

-

04-27-2011, 05:16 PM #1

Magnetic Table-top Strop with rubber feet, and 2 Hanging strops

Magnetic Table-top Strop with rubber feet, and 2 Hanging strops

I had a few days to myself and decided to make myself some more gear.

First off, I made a table-top stropping hone with a metal top surface for various magnetic pads, and mounted some rubber feet to the bottom for a non-slip grip to any surface.

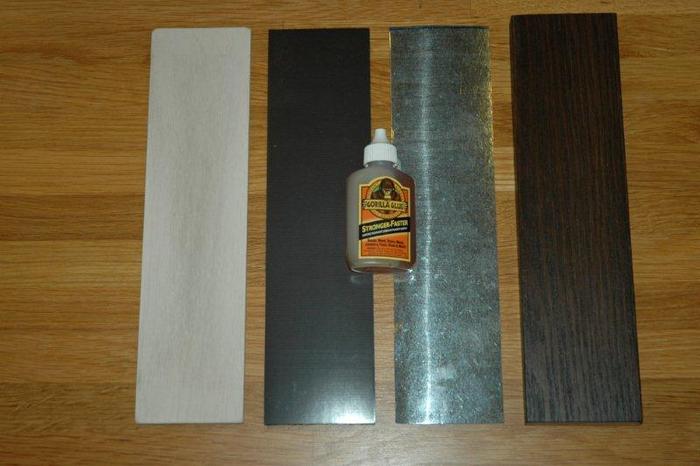

I used Gorilla glue (excellent stuff) to mount a thin piece of sheet metal to a piece of 3"x12" wood, and clamped it for a couple hours, and then mounted the 3M rubber feet to the bottom of it.

Then I made some various magnet pads to experiment with. I used an A5 magnetic sheet that I bought from a stationary shop, and cut some 3"x12" strips from it. I used my trusty Gorilla glue again to mount & clamp the first one with balsa wood (coated with 0.5 micron diamond spray). The second and third pads I made with some top grade leather that I bought for strops. I empregnated one of them with 0.5 micron Chromium oxide, and the other one I just left as-is for a perfect finish.

The raw materials cut to size & ready for the Gorilla glue!

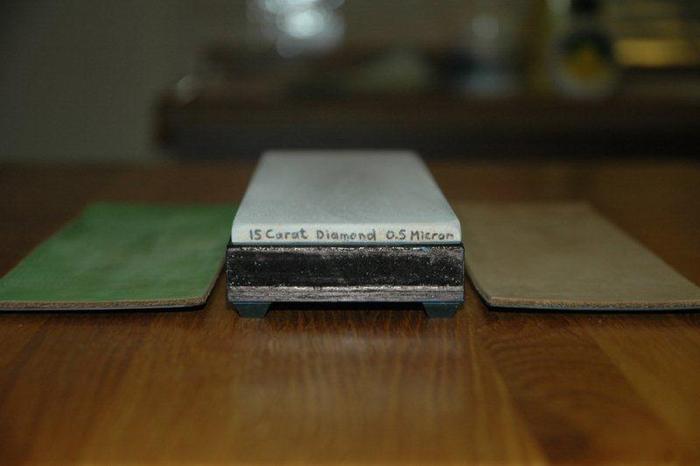

Pad materials cut, treated & ready to be glued to the magnetic strips.

All done. Chromium oxide leather on the left, balsa pad mounted on top, and plain leather on the right.

The whole set neatly packs together.

Next up, I decided to make myself some more strops (a man can never have too many strops, right?)

Got hold of some absolutely phenomenal top grain leather from a leather supplier, and bought some extra bits and pieces(clips, hooks, 2-sided leather screws etc.) from leather craft shops. It took a fair bit of time, but they came out really nice, and they work really well.

Leather & plain cotton weave strop at the top, and at the bottom is a twin cotton strop with diamond spray on one, and Chromium Oxide on the other one.

After all of this, it was time for some serious honing. I honed these babies up to 12K Naniwas, and finished them off on my newly made table-top stropping hone with the diamond balsa wood, ChrOx leather pad, and then finally the plain top-grade leather pad.

A beautiful Barber's use only 8/8 Wade & Butcher with original horn scales. (Jaw-dropping shave!)

My 9/8 Wade & butcher wedge that I have not restored because of the faded masonic markings on the blade and the horn scales in great condition. (Also a beauty to shave with)

A masonic Wade & butcher 6/8 full wedge that I spent a heck of a lot of time restoring. I removed all the pitting, hand-sanded for about 15 hours to a mirror and then went back to a satin finish. I re-pinned the rear pin with stainless steel washer and pin, and re-seated the worn-out pin pivot hole inside. She's a real eye catcher and a great shaver now!

Last edited by JimmyHAD; 05-05-2011 at 03:45 PM. Reason: Changing title at author's request

-

The Following 4 Users Say Thank You to leadingedge For This Useful Post:

baldy (04-27-2011), gllh17 (05-27-2011), MileMarker60 (04-28-2011), wukong (04-27-2011)

-

04-27-2011, 06:12 PM #2

My word, you are right. You have been very busy indeed.

Looks like some really neat stuff!

Hope you get lots of good use from all those fine products!Bjoernar

Um, all of them, any of them that have been in front of me over all these years....

-

The Following User Says Thank You to Birnando For This Useful Post:

leadingedge (04-28-2011)

-

04-27-2011, 06:48 PM #3

Good stuff!

-

The Following User Says Thank You to Moonshine For This Useful Post:

leadingedge (04-28-2011)

-

04-27-2011, 07:02 PM #4

Great work! You are certainly a multi-talented person! Kudos!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

The Following User Says Thank You to sharptonn For This Useful Post:

leadingedge (04-28-2011)

-

04-28-2011, 03:53 AM #5

Very impressive work.

Thanks for pictures and words of explanation, highly beneficial to novice like me.

Will try to make my own leather paddle based on this.

-

The Following User Says Thank You to wukong For This Useful Post:

leadingedge (04-28-2011)

-

04-28-2011, 04:49 AM #6

No problem Wukong, glad to help out where I can!

As requested by some guys, I will try and create an article in the wiki section on the paddle & strops in the near future when I get a chance.

-

The Following User Says Thank You to leadingedge For This Useful Post:

wukong (04-28-2011)

-

04-28-2011, 05:26 AM #7

Okay, I've found some wood I could use. Picked up some wood laths near a rubbish dump on my way home, if cleaned and paper-sanded correctly should do it.

I have to go and buy a saw tonight!

As for the metal sheet I don't know yet but I could dismantle something in my apartment like the fridge door and tell my wife a thief did it while we were not home... you never know what a straight shaver is capable of just to expand his shaving equipment!

and tell my wife a thief did it while we were not home... you never know what a straight shaver is capable of just to expand his shaving equipment!

-

04-28-2011, 06:51 AM #8

Heck, now that's dedication for you!

Who needs a fridge door when you can have straight razor equipment!

Who needs a fridge door when you can have straight razor equipment!

For the metal sheet, what you should be able to find quite easily, is just plain old roofing galvanised steel. Obviously the corrugated type won't do, so just get a thin flat sheet of galvanised steel from your hardware store when you purchase your saw.

You can cut thin galvanised steel with a plain old pair of scissors, in fact, that is what I used for this project. My metal cutting scissors were not precise enough, so I took a pair of old kitchen scissors instead.

Try to buy some type of general use epoxy glue, and spread it thinly & evenly over the surface, then clamp it together tightly between 2 flat pieces of wood (or any 2 flat surfaces) for a few hours while it dries. The clamping is important, to ensure that the metal is completely flat after the epoxy has dried.

I would recommend using baking wax paper between the pieces of wood or flat surfaces that you use to clamp your project with, because when the epoxy squeezes out during clamping, it will get stuck to your flat surfaces you are clamping with! Wax baking paper works very well, because almost nothing sticks to it.

Post pics, and ask as many questions as you want. Remember, there's no such thing as a stupid question.

Last edited by leadingedge; 04-28-2011 at 07:52 AM. Reason: Finger trouble

-

04-28-2011, 10:48 AM #9..mama I know we broke the rules...

- Join Date

- Feb 2010

- Location

- Toronto, Ontario, Canada

- Posts

- 2,895

- Blog Entries

- 8

Thanked: 993

Love the look of the new strops and bench hone. Nice stuff!

-

The Following User Says Thank You to Maxi For This Useful Post:

leadingedge (04-28-2011)

-

04-28-2011, 02:53 PM #10

Very innovative and a great ideas there, especially with the benchtop strop.

It looks very handy indeed, I love it. How does it work, does the magnetic pad hold well?

And where did you get the cotton for the other strops?

Nicely done, thanks for posting.

-

The Following User Says Thank You to str8fencer For This Useful Post:

leadingedge (04-28-2011)

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote