Results 21 to 29 of 29

Thread: SRD Materials

-

08-11-2014, 11:55 PM #21

These charts seem to vary widely but here's one that will give you an idea of micron to grit conversion:

GRIT MESH MICRON

100,000 0- 0.5 1/4

60,000 0-1 1/2

14,000 0-2 1

13,000 1-2 1.5

9,000 2-3 2.5

8,000 2-4 3

5,000 2-6 4

4,500 4-6 5

2,800 5-10 7

1,800 6-12 9

1,400 8-20 14

1,200 10-20 15

1,050 12-25 18

800 20-30 25

600 20-40 30

500 30-40 35

325 40-50 45

285 50-60 55

240 60-80 70

225 80-100 90

160 100-120 110

100 120-160 150

So... According to this chart, 1/4 or 0.25 micron is 100,000 grit. After using 0.25 diamond on balsa after a Zulu Grey or JNat the difference under my microscope is subtle - the scratch pattern is largely unaltered but the edge is smoother - the difference after a good stropping is much more apparent.

John******************************************

"The early bird gets the worm but the second mouse gets the cheese." -Steven Wright

-

08-12-2014, 03:08 AM #22Member

- Join Date

- Jun 2014

- Posts

- 38

Thanked: 7

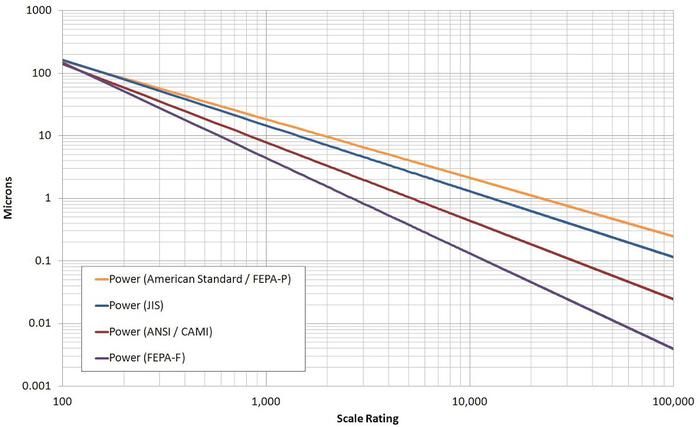

I grabbed this graph from another thread on this site. I forgot which thread as I was doing random searches when researching stones to buy or researching sandpaper honing. I cannot seem to find it anymore. There are also charts but I find the graph to be easier to read. I did not make this graph.

I find it to be useful for choosing spray sizes. I also think the spray should have a higher grit compared to the highest grit stone you have. I could be wrong.

It shows the conversion of the different grit size standards into microns. It seems that not all grits are equal. I have naniwa stones so I follow the JIS line. I am not sure about shapton, maybe american standard? You can just check the microns the shapton 16k (above 1 micron, 1.5?) and just use a lower micron size.

I use a crox spray on fabric webbing and it works fine for me. I actually enjoy the sound. it is like feedback for me. Never tried felt yet.

Last edited by lostinhk; 08-12-2014 at 03:11 AM. Reason: fix an error.

-

08-13-2014, 03:00 AM #23

I have been using this one for years.

Grit Comparison Aug-6-2009.pdf

Grit to micron to ANSI/CAMI, FEPA, JIS old and new, Shapton, Norton, DMT, Trizact cross reference. If it is not in there, it does not exist.

-

08-13-2014, 03:07 AM #24

Now back on topic, I have been using a Straight Razor Designs 3" Premium IV (Long) English Bridle Strop for 6 or so years with the nylon with 0.5 micron chrome ox on the inside and plain on the outside. Works like a charm. Has about 3000 stropping sessions on it and it is about broken in.

-

08-13-2014, 11:45 AM #25Senior Member

- Join Date

- Sep 2013

- Location

- Crestview, FL

- Posts

- 117

Thanked: 3

Has anyone noticed any significant difference in how a poly-webbing strop performs with different abrasives? I have .3 micron chromium oxide on my strop now and it works great. I don't have any more chromium oxide to re-apply. How long do the abrasives last? I'm sure this is dependent on the amount of use. If I use it every day between every shave is an estimate that the CO will last one week or one year? I suppose I'll see a difference in performance. But when I do need to apply more abrasive is there any abrasive that works better than others? A lot of videos I've seen show folks using bars that they rub the strop with. Most have a green color I think. Right now I have sprays under 1 micron. I have .1 micron and .5 micron CBN and .25 micron diamond spray. When I want to reapply should I just use what I have on hand or should I get something else. I've been using the sprays on leather for my knives for 2-3 years and love them.

So anyone who has tried different abrasives can you make a recommendation? Use what I have or get something else? I have gone out of my way to experiment with stones and strops for knives and I really don't want to go through that again. I don't see why the sprays I have now won't work on razors as well as they work on knives.

The poly webbing looks like a material that if gotten wet it won't hurt it. If you have an abrasive on there and you want to get it off so you can use something of lower grit can you wash it off?

I appreciate any help.

Jack

-

08-13-2014, 03:04 PM #26

- Join Date

- May 2005

- Location

- St. Louis, Missouri, United States

- Posts

- 8,454

- Blog Entries

- 2

Thanked: 4942

In my opinion, the poly webbing works best with the crayon or thick paste type media. For the wet type media like the sprays, I like the Felt.

Have fun.

-

The Following User Says Thank You to Lynn For This Useful Post:

Txshooter38 (08-14-2014)

-

08-13-2014, 08:55 PM #27

-

08-24-2014, 02:37 PM #28Senior Member

- Join Date

- Feb 2014

- Location

- Florida panhandle, near Ft. Walton Bch.

- Posts

- 247

Thanked: 23

I got a linen replacement strop from SRD. It's called premium fabric on SRD. It is a lot stiffer than I expected. Do they get softer over time? Right now it's STIFF. If they do get softer is there a way to speed the process up? I'm new to hanging strops and the materials they are made of so I really don't know what to expect or how they will break in or not break in. I might like it better if it stays stiff over time but right now I'd say I prefer the webbing material. I am hoping the linen strop gets softer in time. Any thoughts?

-

09-16-2014, 02:46 PM #29

13Likes

13Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote