Results 21 to 30 of 34

Threaded View

-

06-26-2014, 03:05 AM #1

DIY cutting Inlay strips & inlay engraving jig

DIY cutting Inlay strips & inlay engraving jig

G’day all,

I am trying something different for a Str8 for my son in-lay for his Bday (a new convertee)

so I thought I would add this tutorial of the process I have come up with, so others may be able benefit from it.

now I wanted to try and add his surname name in Runes as a inlay to the scales as per a tattoo he has.

so my first practice attempts free hand were rubbish to put it nicely, as the runes are made up of straight lines & that just wasn’t happening free hand for me,

so back to the drawing board to rethink my process & this is what came out of the mush in my head.

first problem I have a couple of abalone shell strips but not enough & I wanted the inlay to stand out a bit more and wanted to use bone in the black horn scales.

so first cutting inlay strips

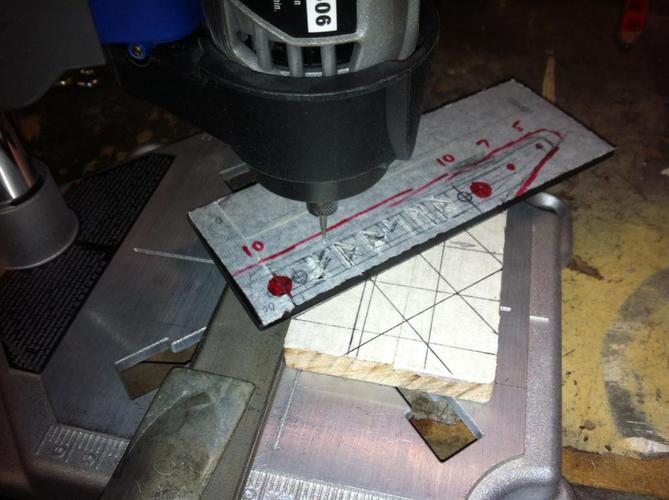

I set up the dremel to the recently acquired drill press arrangement I got for my Birthday a couple weeks back, with the diamond cutting disk,

set it at about 1mm off the base.

used this to cut down some 1mm bone inlay blank made some nice slices

also used the same set up on a bit of horn for black in pieces.

easy as.

then to the fun bit for how to engrave the scale materials for the inlays

the grey matter thought of the guided sliding jig set up as follows:

I clamped a straight bar to my drill press base that I could adjust to suit the width changes,

then made a sliding block from a piece of wood I taped 1 side & marked the angles for my lines on it

sanded 1 side of the horn blank flat as normal as my inside to ensure the scales are flat

then tapped & marked the design on the horn material.

I stuck my piece of horn to the block at the corresponding angles using a small bit of double sided tape

I fitted the 1mm tungsten burr to the dremel,

set the depth gauge stopper on the press to about 1.5mm of movement a bit deeper than the inlay materials so I can shape the scales down to the inlay,

used 1 hand to lower the bit & the other to hold & move the slide block

Attachment 170883

re-adjusted the guide bar to suit each vertical inlay line as I moved across

then removed the horn from my block rotated to the next angle tapped back to the slide block

& repeated for the rest

Saved,

Saved,

to shave another day.

-

81Likes

81Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote