Results 1 to 10 of 34

Hybrid View

-

06-26-2014, 03:38 AM #1

Great work mate !!....I can appreciate the difficulty factor in this.

You're lucky though, his name is in runes, the inlays are all "straight", I guess "curves" would be far more difficult ?

This tutorial throws up all sorts of possibilities....Thanks for posting http://straightrazorplace.com/workshop/18504-welcome-workshop-how-do-i-where-do-i-what-do-i-answers-here.html

http://straightrazorplace.com/workshop/18504-welcome-workshop-how-do-i-where-do-i-what-do-i-answers-here.html

-

06-26-2014, 04:08 AM #2

Nice Work. I've done wood inlay and can appreciate what you are going through.

They make x-y adjustable drill press vices that you can use as an engraving jig. I haven't seen one for a dremel, but they probably exist.Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

-

06-26-2014, 04:39 AM #3

Saved,

Saved,

to shave another day.

-

06-26-2014, 04:59 AM #4Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

The Engraver's Cafe - The World's Largest Hand Engraving Community

You have to create an account to see the pics but well worth it if you can pass the test. I made a lucky guess and got in :<0)Good judgment comes from experience, and experience....well that comes from poor judgment.

-

-

07-07-2014, 02:18 AM #5

bit of an update on the progress of this one

so I decided to redo the Rune inlay cut outs etc as I didn't like the lettering as it was so I started again

also added some Paua dots, I used a similar process to do these but with a different Ø3mm milling type bit to the recesses

Rune inlays were glued with CA & sanded back flush with Paua shell inlays dots added & glued ready for sanding again

also decided to use a John Holler "Celebrated" 6/8" square point wedge I was waiting on for this project

below is the pinning recess for the wedge pin under the inlay dot with a washer in place

pre assembly of bone wedge with Bass liners wedge

Pre assembly

pinning in the wedge recess before glueing the Paua inlay dots to wedge end (looks rather ordinary, but no one ever see it again hopefully)

the wedge end inlays are now drying ready for final sanding & clean up of scales

hope you can follow by rantings LOLSaved,

to shave another day.

-

07-07-2014, 02:26 AM #6

-

07-07-2014, 02:31 AM #7

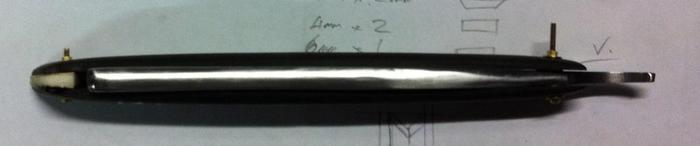

So while the glues are drying etc, I have started the work on the blade

1st off redrilled the pivot hole with a small rotary grinding bit

Resized the hole using 2 brass tube sizes to fit the 1/16" brass pin

I also use a large centre punch to flare the tube ends so they are fixed into the blade before I sand it all flush

now due to a couple of blemishes on the blade that I have to sand,

I am going to try a matt/satin finish so have starting sanding the blade back to 600 W&D using WD40

and will prgress up from there back to 2000 with the WD40 & see how it comes out

keep yas all posted on thisSaved,

to shave another day.

-

-

07-07-2014, 02:32 AM #8

-

07-07-2014, 02:44 AM #9

it was a small greenish blue dremel cone shaped item, it went from about 3mm to 5mm over a 10mm long cone then the normal dremel shaft.

it came in a dremel engraving kit, but I unfortunatley broke it getting a bit keen as I did final sizing it grabbed & broke the tip off

I used it from each side a bit at a time using the dremel drill press set up.Saved,

to shave another day.

-

-

07-08-2014, 09:31 AM #10

81Likes

81Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote