Results 11 to 20 of 48

Thread: What type of drill bit?

-

07-13-2014, 04:12 PM #11Senior Member

- Join Date

- Jun 2014

- Location

- CT

- Posts

- 229

Thanked: 25

I have drilled hardened knife tangs with the masonry drill bits before, but have also melted some of those same bits, too

Not sure if they have a size small enough to end with a 1/8" hole or not? I have some of the bits in 5/32", not sure of the final hole size yet. Carbide may work, or a narrow diamond bit in a Dremel? A #30 wire bit will allow clearance for a true 1/8" diameter pin w/o binding. A 1/8" pin will usually not fit into a hole drilled by a 1/8" pin.

Not sure if they have a size small enough to end with a 1/8" hole or not? I have some of the bits in 5/32", not sure of the final hole size yet. Carbide may work, or a narrow diamond bit in a Dremel? A #30 wire bit will allow clearance for a true 1/8" diameter pin w/o binding. A 1/8" pin will usually not fit into a hole drilled by a 1/8" pin.

-

The Following User Says Thank You to taz575 For This Useful Post:

UKRob (07-14-2014)

-

07-13-2014, 04:31 PM #12

Or you could just anneal the pivot area. A carbide drill is very fragile so make sure there is no lateral pressure or it will snap if subjected to torque. Carbide prefers high speed and plenty of cutting lube.

əˌfisyəˈnädō | pərˈfekSH(ə)nəst | eS'prəSSo | düvəl ləvər

-

The Following User Says Thank You to Maximilian For This Useful Post:

UKRob (07-14-2014)

-

07-13-2014, 05:27 PM #13

-

The Following User Says Thank You to carrolljc For This Useful Post:

UKRob (07-14-2014)

-

07-13-2014, 05:31 PM #14Senior Member

- Join Date

- Jun 2014

- Location

- CT

- Posts

- 229

Thanked: 25

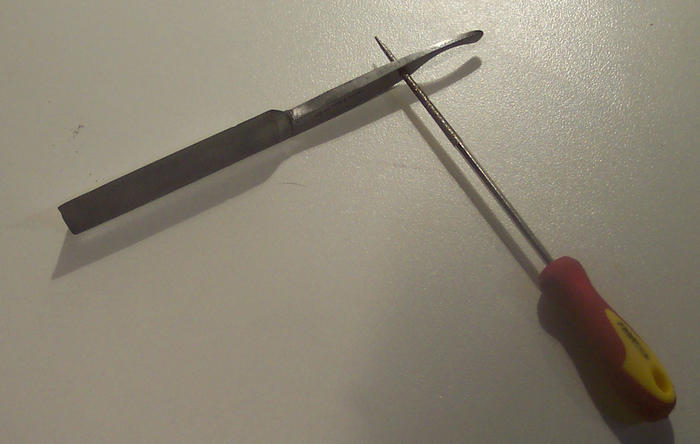

Hmmm. Would cutting off the handle of the HF diamond needle file and chucking it into a drill press/drill/Dremel work faster?

-

The Following User Says Thank You to taz575 For This Useful Post:

UKRob (07-14-2014)

-

07-13-2014, 05:40 PM #15

There are carbide tipped metal cutting drills too, but they are expensive. A buddy of mine has carbide tipped end mills and has used them on various tough projects, like drilling into a weld, or steel adjacent to a weld. One thing he taught me, for reaming holes in tattoo machine tube vises, is to start that drill press and shut it down as you put pressure on the work. Back it off and start/stop again, and again, until you are through the work.

As when we used to ream holes on structural steel bridge and building work, get your reamer, in this case bit, spinning before you go to contact with the work. In the case of reaming holes on structural steel we went on through once we started. I reaming a hole thorough hardened razor tangs I'm not sure if that start/stop would work but it is less likely that you'll burn or break the bit IMHO. I could be wrong though, I was wrong once before. Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

The Following User Says Thank You to JimmyHAD For This Useful Post:

UKRob (07-14-2014)

-

07-13-2014, 09:44 PM #16

Lacking a ridged setup and coolant that is needed for solid carbide drill bits, I have used both diamond needle files and diamond burrs on dremel type tools to enlarge pivot holes. There is not much metal to remove, the task goes rather quickly with a diamond file.

Charlie

-

-

07-13-2014, 09:52 PM #17Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

The Following User Says Thank You to pixelfixed For This Useful Post:

UKRob (07-14-2014)

-

07-13-2014, 10:22 PM #18No that's not me in the picture

- Join Date

- May 2013

- Location

- Los Angeles South Bay

- Posts

- 1,340

Thanked: 284

Can you epoxy or deform brass into the hole and then drill?

That Rodgers I did had a funcky shaped hole, but the brass bushing just has to fit snug, doesn't need a perfect parent hole. JMO. You're just trying to reduce the slop right?I love living in the past...

-

The Following User Says Thank You to RoyalCake For This Useful Post:

UKRob (07-14-2014)

-

07-13-2014, 10:39 PM #19Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Last edited by pixelfixed; 07-13-2014 at 11:03 PM.

CAUTION

Dangerous within 1 Mile

-

-

07-14-2014, 08:00 AM #20

49Likes

49Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote