Results 11 to 20 of 47

Thread: Some rather basic questions...

-

01-10-2015, 05:29 PM #11Member

- Join Date

- Jan 2015

- Location

- London

- Posts

- 31

Thanked: 1

I appreciate your advice but sometimes I like to work things out myself from first principles (I have an engineering degree). If the spine is taped and only the edge is worked on then the geometry will change - the angle of the edge will become less acute - especially if you have chips in the blade which are about 1/16" deep as mine were. I believe my father must have used the razors for DIY tasks after they ceased to be used for shaving, hence the extensive damage.

If - and I admit it is a big if - I can a do an accurate re grind of the hollow to reduce the width of the honing surfaces I believe I will have made a very serviceable and good-looking razor from one which otherwise would most probably have been thrown away.

My sister has just found two more of my father's old razors including one marked "John Tingle" of Sheffield. This also has a badly chipped blade, no doubt from having been abused in the same way. I will see how things go with the Hunter & Son before I tackle this one.

-

01-10-2015, 05:50 PM #12

i am not sure what the implications to the temper would be if you re-grind the razor i don't do this kind of thing, so i cant help any more than that. as has been said tape may have saved the spine, the bevel angle could be calculated fairly easily, and i think that though around 18 degrees is the ideal there is some leeway.

Bread and water can so easily become tea and toast

-

01-11-2015, 01:36 AM #13

-

01-11-2015, 02:16 AM #14

Hopefully, not too late. There is some merit for going the http://straightrazorpalace.com/works...r-cleaner.html Tumbler approach, as I understand.

It does look like alot of metal was removed. Unpinning the razors and dropping them into a tumbler with the right media and you may have avoided it.

Hope that helps, Nigel.

ooooH. Sorry. Read the couple post above. It seems you've answered your own questions.

Kind regards,

SiguyLast edited by Siguy; 01-11-2015 at 02:19 AM.

-

01-11-2015, 02:41 AM #15Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

So… did you have a question?

The whole spine/ tape/ angle/ theory is a myth, disproven long ago, though there are some that still believe it, even in the face of fact.

You are needlessly disfiguring your razors and possibly making them unable to hold a shaving edge.

It sounds like you have already decided how you want to “repair” your razors… against experience and practical advice, so enjoy.

Thanks for showing us you razors…

-

01-11-2015, 08:02 AM #16Member

- Join Date

- Jan 2015

- Location

- London

- Posts

- 31

Thanked: 1

Wow, it's great to see such passion for the protection of what were, when they were made, rather commonplace utilitarian objects.

I did look at some video clips made by guys who look like pros before I started and I have recently found another one along the same lines which makes perfect sense to me and is what I had in mind (please tell me if you disagree):

My hone wear is very much less than the examples he shows which he says do not need regrinding, which I find most reassuring. My hone wear is a little uneven however because I was focussing too much on taking out the chips, which were concentrated at one end, than on keeping it even. I acknowledge that this was a mistake but I believe I can largely correct it by doing some more honing at the other end of the blade, and if that doesn't work out satisfactorily I have the option to regrind as in the clip. If I ruin the razor it will be a shame but I will learn from it. Other than damaging the cutting edge further, overheating when grinding is probably the greatest risk. If this happens I would have to take it apart and heat treat it - something I have done before when making tools, but I would rather not have to.

My next restoration project is a 17th Century lantern clock but I am taking this to a specialist clock repair class as it's probably worth more than a hundred times as much as my razor and I really don't want to ruin that!

-

01-11-2015, 08:17 AM #17

-

01-11-2015, 09:14 AM #18Member

- Join Date

- Jan 2015

- Location

- London

- Posts

- 31

Thanked: 1

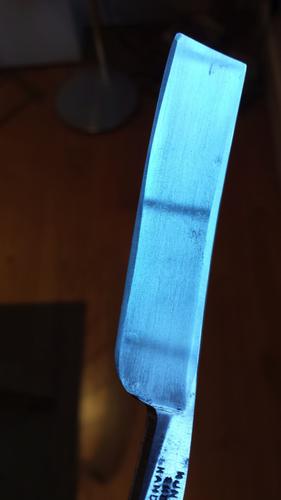

OK here are some better pictures. I am genuinely interested to learn what you think I have done that is fundamentally so wrong, because as yet I can't see it.

The hones have been done only on flat relatively fine stones and the hollows have been cleaned of rust by hand using sand and emery papers, and could benefit from further polishing.

-

01-11-2015, 07:35 PM #19Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

Usually the goal in restoring is to leave as much metal as possible on the razor. Without before shots it is hard to tell what you did and what was there before. If what you are saying is all the wear was done by you, then I think it is obvious what is wrong.

Usually the goal in restoring is to leave as much metal as possible on the razor. Without before shots it is hard to tell what you did and what was there before. If what you are saying is all the wear was done by you, then I think it is obvious what is wrong.

Umm re heat treating a razor is not an option. The heat treating is done before the final grind. The reason for this is that during heat treating the chances of survival for anything under .0625 in thickness is doomed to warp or crack.Good judgment comes from experience, and experience....well that comes from poor judgment.

-

01-12-2015, 06:18 AM #20Member

- Join Date

- Jan 2015

- Location

- London

- Posts

- 31

Thanked: 1

I agree that re heat treating would be problematic and a pretty drastic option, which is why one would want to avoid having to do it.

I reckon that I have doubled the width of the hone area at the edge. I believe this was unavoidable given the size and number of chips in it. In fact I only honed the minimum amount to remove the chips. To have taken out the chips without increasing the hone area would have been a geometrical impossibility, short of regrinding the hollow (which I have now decided is not necessary).

My principal goal in restoring was so that I could use it regularly to shave with. This objective has now been met. The razor is interesting but not especially valuable. In fact it probably belongs to the British Government though I doubt they would want it back. On one of the scales is faintly stamped W ^ D 1 (the second character being the British Government broadarrow symbol). WD stands for War Department so this was a military issue. It looks too early to have been WWII and since my grandfather was too old to fight in WWI it could have belonged to a great uncle who joined the army as a regular soldier in Queen Victoria's reign and rose to become the bandmaster of Prince Albert's own Hussars. Photos show him with a good moustache and set of whiskers but as an army man he would not have been allowed a beard (the Royal Navy, of course did allow beards).Last edited by NigelW; 01-12-2015 at 06:23 AM.

47Likes

47Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote