Results 21 to 30 of 47

Thread: Some rather basic questions...

-

01-12-2015, 10:12 AM #21Member

- Join Date

- Jan 2015

- Location

- London

- Posts

- 31

Thanked: 1

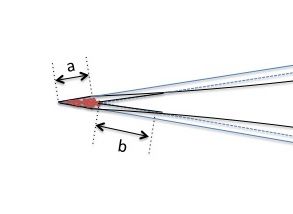

This cross section diagram illustrates what I did to my razor. The red area indicates damage. a is the width of the honing area before and b is the width after. If I had taped the spine b would have been very fractionally less but the effect would have been a second order one.

-

01-12-2015, 03:28 PM #22Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

"To have taken out the chips without increasing the hone area would have been a geometrical impossibility, short of regrinding the hollow (which I have now decided is not necessary").

This is just not true. We do it all the time without causing all the damage you have.

If you want to do so to your razors go right ahead, but the problem with writing this, is some pore new guy will read this thread and believe you and you donít know what you are talking about.

A couple pieces of tape and proper hones could have easily honed the razor and maintained the proper geometry and caused no damage.

-

01-12-2015, 03:51 PM #23Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,331

Thanked: 3228

Try a different approach to learning to hone a straight razor. For the moment put your engineering experience and experience honing carpentry tools on the shelf and start as if you are completely unfamiliar with straight razor honing. Take the advice you have been given from experienced members and just try applying that advice preferably not on an heirloom razor. It sometimes is easier to approach things that way.

BobLife is a terminal illness in the end

-

01-12-2015, 04:03 PM #24Senior Member

- Join Date

- Nov 2010

- Location

- Pequea, Pennsylvania

- Posts

- 2,290

Thanked: 375

Wouldn't that really depend on the size of the chips that were present? Small chips, I will still use tape. A large chip I think you would be pushing it on the geometry using tape. They should wear together to keep the correct geometry especially with the removal of a large chip. He is basically talking about a restoration right?

I don't see where Nigel is wrong in his thinking...CHRIS

-

01-12-2015, 04:34 PM #25Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Nope…

So here’s the fact.

Never seen a razor that has stopped shaving or the ability to hold an edge from using tape and causing too steep an angle.

But there are many, many razors that have had their spines ground thin that will no longer hold an edge. The fix is to hone with tape…

Now if you taped a razor and you did want to reduce the angle for what ever reason you could always grind the spine, you can NEVER add steel to the spine.

This has been debated over and over and this challenge has been made over and over… still have not seen one… perhaps because they do not exist…

Show me a razor that has stopped shaving because of tape?

-

01-12-2015, 07:31 PM #26Member

- Join Date

- Jan 2015

- Location

- London

- Posts

- 31

Thanked: 1

Since your nom de plume is Euclid I would have though the least you could do was to provide a diagram to illustrate your point. If you study mine you will see that there was no geometrically possible way of avoiding increasing the width of the hone area next to the blade when removing a chip of the size shown. Whether or not the spine is taped is immaterial as far as the geometry of the edge is concerned. The only advantage that I can of not increasing the hone area next to the spine it makes the honing quicker in future. The argument that the spine will be badly reduced is simply not true in the case of the recent honing of my razor, which is a substantial wedge.

-

01-12-2015, 07:57 PM #27Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,331

Thanked: 3228

If you want diagrams http://www.coticule.be/wedges.html . Download the excel file to do the bevel angle calculations for your razor without tape and with different multiples of tape. It can also be used with hollow ground blades and anything in between.

Most of what people refer to as wedges today are not true wedges but merely heavy grinds. So long as the blade has any concavity to it then it is not a true wedge. A flat sided true wedge would be a bugger to hone without the use of a temporary false spine while honing. I don't think a diagram is necessary to picture that in the minds eye.

BobLife is a terminal illness in the end

-

01-12-2015, 07:59 PM #28

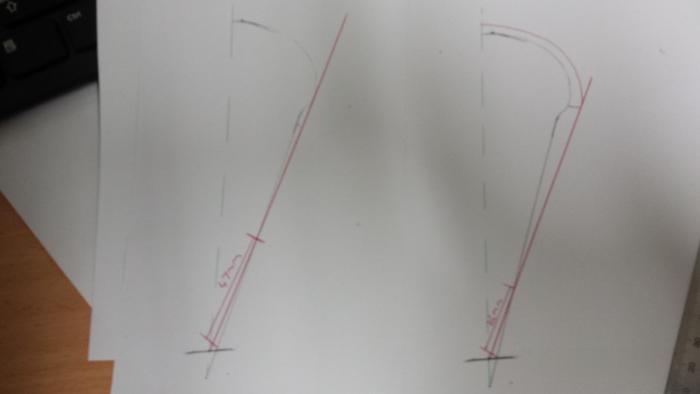

Please Forgive My Rather Crude Drawing, as you can see, the right hand profile has a considerably smaller bevel.

the red section around the "spine" is supposed to represent tape.

I also tried extending the bevel lines on your drawing, i would have thought that they would intersect at the spine (not shown) but they seem to just extend almost parallel.

The reason for this was that I was going to overlay some lines on your drawing. It could be because I only have paint available though, it's not terribly good for this sort of thing, hence the hand drawings.Last edited by edhewitt; 01-12-2015 at 10:28 PM.

Bread and water can so easily become tea and toast

-

01-12-2015, 08:15 PM #29Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,331

Thanked: 3228

Ed

All your profiles look good, don't be so modest.

BobLife is a terminal illness in the end

-

01-12-2015, 10:13 PM #30

Nigel,

Bunch of great info already organized over in the Library that might be helpful.

Category:Honing - Straight Razor Place Library

and

Honing a damaged blade - Straight Razor Place Library

are always good reference points.

Cheers!

47Likes

47Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote