Results 11 to 20 of 84

Thread: Crocus finish or Satin?

-

11-26-2015, 08:14 PM #11

I too have noticed a tendency to imply that crocus is something less than a polished finish - especially by people who criticise restorations with a high polish - they seem to think the original blades were not finished this way. Crocus finish is way more shiny than satin.

My service is good, fast and cheap. Select any two and discount the third.

-

11-26-2015, 10:36 PM #12

I had never heard of a crocus finish until reading this thread.

Stan Shaw is the only guy alive who was polishing blades when this way of working was common in industry and he told me he uses emery powder stuck on leather wheels with hide glue for pre-glazing and cotton mops for glazing.

Stan is a living legend

aka Michael Waterhouse

aka Michael Waterhouse

-

The Following 7 Users Say Thank You to mikew For This Useful Post:

Chevhead (11-26-2015), DocMartin0321 (11-26-2015), engine46 (12-15-2015), jmercer (12-13-2015), Slawman (12-13-2015), Substance (11-27-2015), Wolfpack34 (11-27-2015)

-

11-27-2015, 12:39 AM #13

Some input from Neil Miller here:

http://straightrazorpalace.com/razor...ck-polish.htmlThe white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

The Following User Says Thank You to onimaru55 For This Useful Post:

ScottGoodman (12-16-2015)

-

11-27-2015, 06:00 AM #14Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Just my 2 pence but glazing is the Sheffield word for polishing. Still now as it always was.

Right, but there was a glazed finish, more of a satin finish and a Crocus or “black” shiny, mirror type finish and some now call a mirror shiny finish a glazed finish and some use the terms interchangeably, but they are not.

Both were applied with hard, wooden hide covered wheels. The money, stamped side was often polished bright with crocus and the pile side left dull or more of a satin finish. More for knives than razors I think. I read somewhere that Sheffield “sealed and burnished” (as they called it) the finish with, Crocus to better protect razors from rust. Burnished with a hard wheel.

Interestingly, you don’t see as many old neglected Sheffield razors with red rust, not like you do with other razors, perhaps they knew what they were talking about…

What is sad, is the intricacies of the whole process, seem to have been lost and many of the tools do not exist anymore. I have talked with guys and read where some have tried with other leathers and hard felts, but cannot achieve the same level of finish.

On one of the threads, I think the one I linked, they talked about dipping a piece of a felt hat in oil and Crocus powder to apply a thin coating to the wheel, (it was applied in thin layers, daily) and then burnishing the Crocus wheel with a pebble, prior to polishing for the final finish. Those little details are the tricks and tips that only come from learning at the shoulder from one of these old masters that did this for many years, kids when they started.

I would love to watch Stan Shaw work, for a couple of days and just pick his brain and examine his tools. Soon the whole process will be lost forever.

-

11-27-2015, 08:21 AM #15

Stan loves to talk and is happy to share his knowledge. If ever you fancy a visit look me up

There are still a handful of younger makers in Sheffield with direct links to the 'old ways' but their machinery has moved on a bit since Victorian times! Steven Cocker and Stuart Mitchell are both good guys to talk too.

I've got some video footage of Stan's workshop if you are interested....aka Michael Waterhouse

-

-

11-27-2015, 06:07 PM #16Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yes, I would love to see that, is it on line somewhere. I have always been one of those that look in the corners of shop photos to get a glimpse of a shop and tools and jigs that craftsman use.

I did look up Steve Crocker and look at his postings on Facebook and his Photobucket library. Wow, some beautiful work, I especially love his pocket knives. Those done in jigged and picked bone, stag, horn and Mother of pearl are just amazing as is his spine worked blades. He also produces some amazing bright finishes and I do like his remake of classic style & design. Love the photos of the Parsers and templates and one in use.

Do you know if the design books he has photographed and used as backgrounds, with drawing and design descriptions and notes written in pen ink are his or old Sheffield design books?

Here is the Photobucket link for Steven Crocker.

And Stewart Mitchell’s work more in the fixed blade modern style, I do love his workshop photos and his photographic eye, one can see where his design style comes from. On the home page there is a gorgeous leather knife roll, I may have to try and duplicate… Very nice work and photos. Here is a link to his workshop to Stewart Mitchell’s website.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Geezer (01-05-2016)

-

11-27-2015, 07:45 PM #17

Good post Marty. You are right that a 'true Crocus Finish' is a very bright mirror finish, and a brighter 'satin finish' is actually what I am doing with a lot of my blades, accomplished by using a crocus cloth or crocus paste and a wheel. My process is time intensive but not hard to imitate. I will finish a blade with 400 grit and then mirror polish it with black and then white Emory. Then I will lightly 're-glaze' the steel with 800 grit and then polish that with crocus paste. The final look is a polished steel that is what I call a shiny but 'muted mirror finish'. A polished satin or glazed look.

For some time now I have been hard using leather wheels coated with crocus and also lead and have been having a bit of success with this. Lead when applied with a leather wheel will produce a 'brilliant polished look' and will completely polish out even heavy scratches, as will crocus pasted leather wheels, but like Neil said...it takes a lot of patience and time to perfect these methods, and I am at the very beginning stages of the learning curve.

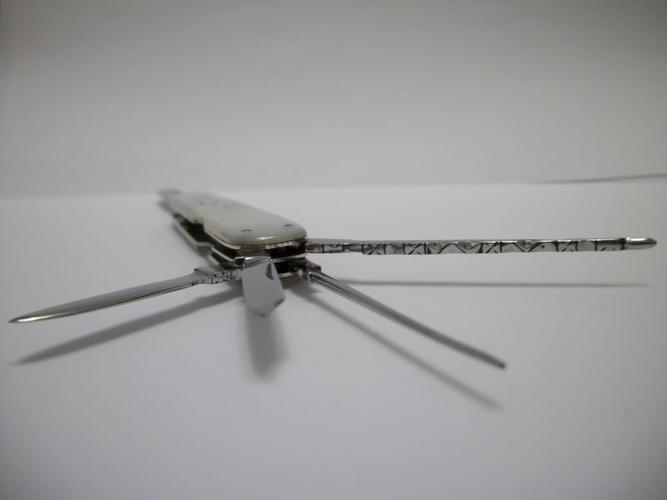

Here's a blade that I recently 'mirror polished' using a combination of a lead covered leather wheel and a crocus leather wheel. As I said..I'm still learning and far from perfect...

Lupus Cohors - Appellant Mors !

-

The Following 8 Users Say Thank You to Wolfpack34 For This Useful Post:

ChopperDave (12-16-2015), DocMartin0321 (11-29-2015), engine46 (12-15-2015), Euclid440 (11-28-2015), Geezer (01-05-2016), Sando (04-01-2017), Substance (11-27-2015), Willisf (01-30-2016)

-

11-28-2015, 12:58 AM #18Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Mike are you using a full leather wheel or a leather covered wooden wheel? Did you make them and where are you getting Crocus powder? And what are you using to stick the Crocus to the wheel?

I was thinking of making a wooden wheel and covering it with Roo hide.

I was going to use Ferrous Oxide from Kremer Pigments.

Nice work.

Thanks

Marty

-

11-28-2015, 04:28 AM #19

Thanks Marty! I'm using a hard solid leather wheel for both the lead and the crocus paste. I'm thinking that a wood wheel with a softer type of leather would be much better to use and I've been meaning to get around to trying to fashion something like this if I can ever find the time. I'll look forward to seeing what you come up with my friend... I picked up the Iron Oxide Pigment Powder, Fe2O3 on EBAY. Very inexpensive, and it seemed fine enough. Ceramic pigment. The lead loads right on the wheel and coats it easily. I made a paste of the Fe203 and beeswax and paraffin and I apply that to the wheel. It works pretty good. I like the idea of using a glue to apply the pigment directly to the leather and I might try that out...

Lupus Cohors - Appellant Mors !

-

-

12-15-2015, 11:11 PM #20

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

The Following 2 Users Say Thank You to onimaru55 For This Useful Post:

Euclid440 (12-16-2015), Wolfpack34 (12-16-2015)

221Likes

221Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote