Results 51 to 60 of 84

Thread: Crocus finish or Satin?

-

05-27-2016, 02:16 PM #51I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

I have not used that one but here a link

4" Beige Polishing Buffing Grinding Wheel Wool Felt Polisher Disc Pad 100x25mm | eBay

4" Dia 1 4" Wide Rock Hard Paramount Felt Wheel Buff Pin Hole Polishing Buffing | eBay

I have a 3" hard felt that I used with black emery but will be switching to crocus for it

I also found 2" hard felt that works well with Dremel.

For the wheels with pin hole I just drill 1/2 on my drill press, they fit very snugly on the buffer then.Stefan

-

The Following User Says Thank You to mainaman For This Useful Post:

karlej (05-27-2016)

-

05-27-2016, 06:29 PM #52I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

I think scotch brite is another type of wheel that might be worth a try. Those look pretty good

https://www.riogrande.com/Product/Sa...ry-Fine/330160

https://www.riogrande.com/Product/3M...l-3-Ply/330541

https://www.riogrande.com/Product/3M...l-2-Ply/330540Stefan

-

The Following User Says Thank You to mainaman For This Useful Post:

karlej (05-27-2016)

-

05-27-2016, 07:05 PM #53

Stefan...I've used scotch bright wheels that 10 Pups and I made and they do work really nice for a satin finish, and they will remove the fine scratches from grease-less. After you have the satin finish that you are satisfied with, if you want to make it more of a 'shinier satin finish', use a loose cotton wheel and crocus paste ( use sparingly so as not to mirror the satin look) for a really nice 'polished satin look'.

Lupus Cohors - Appellant Mors !

-

The Following User Says Thank You to Wolfpack34 For This Useful Post:

mainaman (05-27-2016)

-

05-27-2016, 07:11 PM #54I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

05-27-2016, 10:03 PM #55I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

Made one leather covered wheel.

Mike mentioned that using felt instead of wood as backing works great so I used one of my 2" felt wheels for practice.

I cut the leather slightly shorter than the circumference of the wheel, cut the end at an angle and glued with contact cement. glued the lather to the felt wheel and trued the surface. The wheel loaded very easy, I overdid it so I had to dress it to remove some of the compound. All in all the first attempt was successful. Now I will make several more for black emery, white rouge, and 44 micron crocus.Stefan

-

The Following User Says Thank You to mainaman For This Useful Post:

Wolfpack34 (05-27-2016)

-

05-27-2016, 10:26 PM #56

Wonderful job and pics Stefan. The wheel looks perfect! I'm anxious to hear about your results...

Lupus Cohors - Appellant Mors !

-

The Following User Says Thank You to Wolfpack34 For This Useful Post:

mainaman (05-28-2016)

-

05-28-2016, 07:31 PM #57

I ordered one of the very fine 4 inch Scotchbrite flap wheels. I'm looking forward to experimenting with it.

-

05-29-2016, 03:02 AM #58I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

04-24-2020, 08:43 PM #59some like it wet

- Join Date

- Feb 2013

- Location

- Istanbul

- Posts

- 64

Thanked: 6

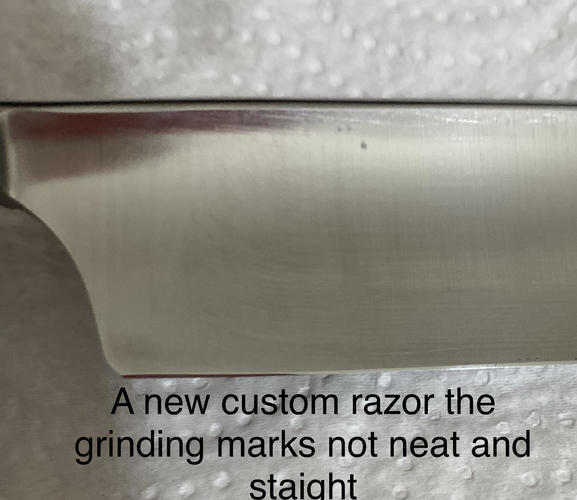

Sorry to revive this old thread, but I have been wondering something about vintage Solingen razors. The semi-polished or satin polished razors have a special pattern of grinding or maybe polishing Whee marks l that you can not achieve that mark pattern with a belt grinder or buffing felt. Maybe I cannot express my idea well enough because my English is not good. If you kindly look at the pictures below I am sure you will understand easily. The marks or trails of grinding or polishing Wheel is very neat and even. there is no up and downs between marks. You can see this pattern even on the razors of these days producers like dovo and wacker, but not on böker razors or french razor producer thiers issard razors. Do you know how can they do this pattern.

Oh yeaah, Some like it wet !!!!!

Oh yeaah, Some like it wet !!!!!

-

04-25-2020, 12:48 AM #60Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

The top razor appears to have grinding marks left over, that were not completely buffed out, then a satin finish was applied, possibly from a scotchbrite wheel.

To get a good satin finish, it must first be polished to a mirror finish,(hand sanded to 2000 wet and dry) then buffed on a hard and loose cotton or soft felt wheel with red or white rouge, then brought down, hand sanded to a satin with 600 wet & dry sanding in one direction only.

There are many good examples, looking at Mike’s (Wolfpack34’s) razors or at Nick Wheeler’s YouTube channel.

What we were trying to achieve in this thread was the Old, pre 1900’s Black Polish finish, a deep flawless mirror finishes of the better-quality Sheffield razors. Made with segmented seal skin wheels and Crocus powder.

I think Mike got pretty close.

On both the middle razor and the last (custom), the stria pattern runs both vertical and horizontal.

Are you trying to replicate the even stria pattern satin finish on the first razor or eliminate all the stria with a mirror finish?

-

The Following User Says Thank You to Euclid440 For This Useful Post:

taskind (04-25-2020)

221Likes

221Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote