Results 61 to 70 of 84

Thread: Crocus finish or Satin?

-

04-25-2020, 02:34 AM #61Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Here are a some pics of a couple of Mike’s, (Wolfpack34) razors, one in satin with bright spine and tang and one full Crocus bright finish.

I have seen Mike’s work in person, and it is flawless. The photos do not do it justice.

Here is the youtube video of Nick Wheeler, how to Satin Finish. I have seen his work in person also, it too is beautiful.

Here is the link to Wheeler Knives how to hand sand a Satin finish.

(

-

The Following User Says Thank You to Euclid440 For This Useful Post:

taskind (04-25-2020)

-

04-25-2020, 07:17 AM #62

I personally like sateen more because of its practicality. If the surface is mirrored, then scratches are visible on it. If satin is applied to the surface, the product looks different.

-

04-25-2020, 08:12 AM #63

Hi Taskin,

well to understand how these steady uniform marks are placed finally on old Solingen razors you need to look at the different steps according to old Solingen razor grinding.

After the razor is ground on the hollow grinding machine with wheels of grits between 60 and 220, the razor runs through through a couple of processes.

The rough grindmarks are taken out by a step called „pliesten“. with leather or strong felt wheels in different diametres for edge, belly and hollow. As mentioned before the wheels are glued with emery, in the old traditional way Naxos emery in grit sizes between 120 and 400. It is important to know that In this step, the original grindmarks are taken nearly completely out.

In the following picture you can see the machine for this step I use in my grinding workshop:

The last step that produces the marks you finally can see on the razor blade surface is the so called „blaupliesten“ or blue polishing. This is done traditionally on walrus leather wheels, slightly glued with emery in a grit size between 200 and 400.

Here you can see a typical old walrus wheel:

There are only a few movements necessary for this step, but you need a lot of experience to get the final „grinding“ marks so perfect steady and uniform on the balde surface as you can see on the old Solingen razors. Also your equipment must be perfect, the polishing shaft must run absolutely vibration free, otherwise you wont achieve really good results. This step also produces a certain blue shining of the blade when you turn it in daylight. That is where the name bluepolishing comes from.

Needles to say, there is no belt grinder used at all for this steps. The only work beltgrinders are used for is for grinding and polishing of spine and tang from the razor.

Regards Peter

-

-

04-25-2020, 12:35 PM #64some like it wet

- Join Date

- Feb 2013

- Location

- Istanbul

- Posts

- 64

Thanked: 6

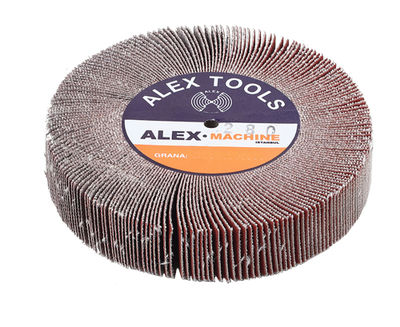

What I am trying is to replicate the pattern satin finish on the first razor. I have tried many things, the best one is this sandpaper mop. But it really eats the metal and you have to try your best polishing to even the marks and that much polishing makes the razor too shiny and erase some marks while leaving others. ofcourse this polishing action is a must to even the steel but It ruins everything.

Oh yeaah, Some like it wet !!!!!

Oh yeaah, Some like it wet !!!!!

-

04-25-2020, 12:46 PM #65some like it wet

- Join Date

- Feb 2013

- Location

- Istanbul

- Posts

- 64

Thanked: 6

Thank you for the info. I made a leather wheel and glued abrasive powder on it but I could not make it . I think I need a good set up, neccesarry material and years of experience. It means I am just about to achieve the god damn lovely marks

Oh yeaah, Some like it wet !!!!!

Oh yeaah, Some like it wet !!!!!

-

04-25-2020, 12:46 PM #66Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Peter, why Walrus leather? I have read and seen photos of Seal skin also used on the larger wheels, where segments were stacked and glued on end to a wooden wheel.

Were the walrus and seal used because they were available or did then have some special properties? Have you tried other leather and did you make your wheels? Is Walrus leather available?

-

04-25-2020, 01:36 PM #67

Well a couple of reasons. First of course, in the older times like the 19th century, they did not have the possibilities of making the lot of variations of felt and other fabricated wheels for this purposes.

Second reason is, Walrus leather could be very thick, at least 3-5 cm thick. So the wheels for razor polishing are simply cut of of the leather in one piece.

Next point is the hardeness of this leather. Walrus leather has exactly the correct hardness for polishing, not too hard, not too soft. An example: If you are polishing the hollow and your polishing wheel is too hard, the scratches in the metal surface get too deep. If the wheel is too soft, you are going to round and ruin the edge from hollow to the razor spine. Walrus leather has exactly the perfect hardness.

And one more reason. The structure of Walrus leather is very porous.

This allows that the abrasive that is applicated to the wheel does not only adhere on the surface but also penetrated into the leather. So you can „store“ some abrasive within the leather that gets reactivated while polishing. Also the glue adheres much better on this porous surface.

The old razor grinders all swear on the use of Walrus. But also in the knife industry, larger Walrus leather wheels, such as you mentioned and as I showed earlier in this thread, were used for the blue polishing.

Today in the knife industry in Solingen there is only one company left who still keeps this tradition and technique alive – Robert Herder windmill knifes.

Today the Walrus is part of species conservation. So trade with Walrus leather is not allowed any more - at least in Germany. There is only the old stock of wheels and pieces of Walrus leather from decades ago.

Regards Peter

-

-

04-25-2020, 02:19 PM #68Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I get a similar pattern from a scotch radial, 220 grit wheels. It is a silicone impregnated with different grits and grit sizes. The radial tines are in alignment and will produce a striated pattern if not moved but will polish well if the work piece is kept moving.

I use it prior to going to a buffing wheel with compound to polish. So, I am not trying to create a pattern, but the opposite to remove any defect and or prior stria patterns. I move the razor horizontally to create a smooth finish and 90 degrees, from heel to toe to even out any stria pattern.

I suppose one could create a similar pattern, if you introduced the razor to the wheel, buff a 1 inch section, lift the razor and buff another 1 inch section until the face was completed or stack several wheel together. I use a 1X6 in wheel.

They are a bit pricy but last a long time, do not throw off bits like a wire wheel and remove much less material than a wire wheel.

I have always felt the pattern you wish to replicate was stria from rushed buffing. I routinely remove that pattern from new Dovo and TI razors and buff to a finer finish. Especially when removing the AOS Dovo logo that is unsightly once scratched.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

taskind (04-25-2020)

-

04-25-2020, 05:55 PM #69some like it wet

- Join Date

- Feb 2013

- Location

- Istanbul

- Posts

- 64

Thanked: 6

Dear Peter,

Do you have any restoration video on youtube or any other media? so that we can watch in these quarantine days.Oh yeaah, Some like it wet !!!!!

-

04-25-2020, 06:19 PM #70Member

- Join Date

- Feb 2016

- Posts

- 32

Thanked: 15

Pliesten with normals knives

https://youtu.be/4sfcDHMkLpU?t=592

-

221Likes

221Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote