Results 81 to 84 of 84

Thread: Crocus finish or Satin?

-

08-05-2020, 11:03 AM #81Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,819

Thanked: 563

It is fascinating to eavesdrop on the conversation between two polishing pros. Thank you.

David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

-

11-07-2020, 06:44 PM #82some like it wet

- Join Date

- Feb 2013

- Location

- Istanbul

- Posts

- 64

Thanked: 6

Dear Peter, @hatzitcho what is that schimergel paste, they put on the blades ( not on the wheel) while they are doing blaupliesten. I saw it in the video of Mr. Breidenbach and in the video of late Mr.master Wilfried Fehrekampf .

Oh yeaah, Some like it wet !!!!!

-

11-08-2020, 10:39 AM #83

Hi Taskin,

it is called Naxos emery and it is the same material the wheels are glued with. For the application during pliesten/ polishing the powdered emery is stired into rapeseed oil and smeared on the razor or on a metall blade and applicated on the wheel.

The emery was produced from abrasive rocks mined on the creek isle of Naxos. The stones had been broken and shipped to Germany and elsewhere. Here special milling companies prepared the powder in different qualities. Coarser qualities had been graded by sieving, finer qualities had been muddled.

For knifes and razors mostly the muddled products have been used. They were graded in 6 degrees, called 1/0, 2/0, ... 6/0. These grades are not directly transferrable to the grits we know today, since the emery doesn't have one defined grit, but a grain size distribution. So it is the same as if you compare natural stones to artificial hones. But concerning the main/max. particles sizes, a 1/0 corresponds to a 180 grit, a 5/0 to approx. 400 grit. For blue polishing Naxos 3/0 or 5/0 is used.

The Solingen production companies did mix some other incredients to the sole emery, such as red iron oxide (this is why the emery is of red color instead of grey - which is the normal color of emery), pumice flour and other polishing substances. The recepture was a strong secret of each company.

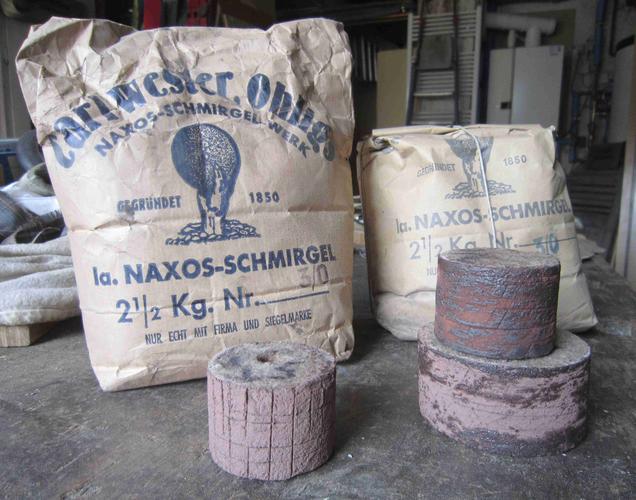

One of the best know companies was Carl Wester, Solingen.

Here is a picture of the original emery bags with label and some wheels that I glued with emery just a few days ago.

Regards Peter

-

The Following User Says Thank You to hatzicho For This Useful Post:

Euclid440 (11-08-2020)

-

11-08-2020, 12:58 PM #84some like it wet

- Join Date

- Feb 2013

- Location

- Istanbul

- Posts

- 64

Thanked: 6

Hi Peter

Thank you indeed. Fog in the brain disappeared.

TaskinOh yeaah, Some like it wet !!!!!

221Likes

221Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote