Results 71 to 80 of 80

Thread: Conundrum Curiosity Complex.

-

07-11-2016, 04:29 PM #71

I thought the idea is to handfeed? A ratchet might just work, there are ones with different spacing depending on which is valued higher, the amount of angle per step and strength. I imagine you're probably not going to put enormous stresses on it, so the finer tooth might be good for a smoother feed rate.

-

08-08-2016, 11:05 AM #72

Been working on the Flexshaft concept. The nickel sized discs I have in a box of random metal are not steel. Myself & a couple of the maintenance men are of the consensus that the discs are plated brass. Which begs the question: why the heck would someone plate brass?!?

In the process of turning one into a twisting/spinning jig for the Flexshaft, I noticed the yellow metal under the thin top layer.

Ran across another disc, seemingly identical, except that it is slightly larger & has a stamping. Haven't researched the stamp yet. Unrelated & completely random curiosities can wait for when I'm killing time, with only my phone for refuge.

I have pics of "during" the making of the twisting jig, but will only add them if requested . Needless to say, not having a drill press is a challenge in itself.

. Needless to say, not having a drill press is a challenge in itself.

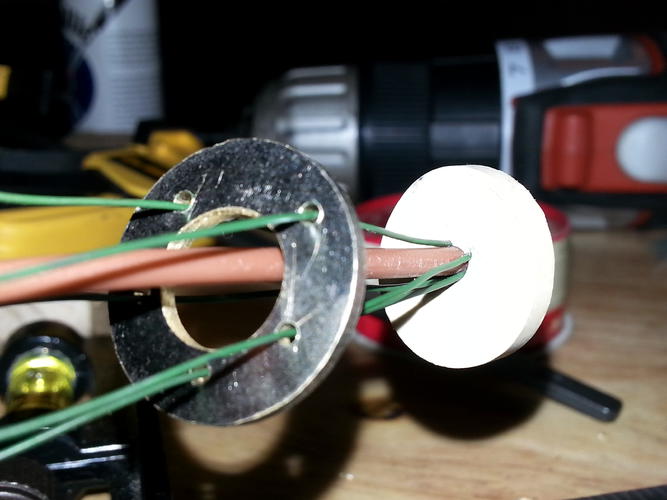

The jig is fitted.

The white thing is rubber stopper for reems of plastic bags. The brown strand is some random bit of plastic that had become dislodged from the underneath side of the front seat of my '96 Park Avenue whe I cleaned it out to scrap it this month. The legit Flexshaft is made with "...a flexible core...". It also gives something to wind the metal wires around. This plastic may not hold up to the stresses of the work, so I may build v.2.0 with a length of weedeater "string". Roughly the same size, I almost never weedeat our small lawn, and I already know it's fairly resilient.

This isn't exactly getting dedicated time, just a few minutes here & there. Tomorrow, hopefully, I'll be able to actually wrap/spin the wires. OCD will be a major obstacle. My jig is not perfect, so there may be trouble getting things done like the "orderly fashion" that is in my head!

G'night folks!

-

08-09-2016, 10:26 AM #73

Belting it out!

Belting it out!

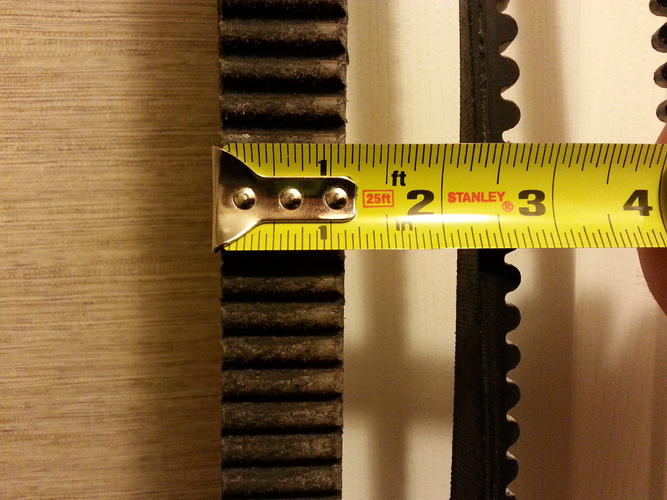

There is a good reason I waited for a certain pair of v-belts to get replaced at work... their huge! These are slated for use as the first link between bicycle & pulleys in the sawmill contraption.

No specific plans for this belt... yet! It is double sided (double cogged?) and flat, if I recall belt descriptions properly.

1-1/8" wide... I could always make my own cogged wheel for it out of wood?

Tonight, my wife asked me: "What is it with the year 2016 & DIY? You have never been remotely this interested in that sort of thing the entire time we've been together."

Decades away from full-beard growing abilities.

Decades away from full-beard growing abilities.

-

08-09-2016, 03:35 PM #74

AWESOME! One of the less useful pulleys can be placed somewhere along the line as a tensioner to save space. If needed.

I do believe the grooves/cogs/whatchamacallems are typically used like gears. At least, they were in my harley. For your purposes, should work out fine.

I think that style is also usually made with kevlar/similar fabric to extend the life, should be a very robust solution.

Good luck with the spinney-wire contraption!

-

08-10-2016, 12:07 AM #75

Eureka!!! The plated brass disc conundrum has been solved! Some quick web-fu brought forth the answer...

Eclipse disc... what is it?

It is a shield of sorts for magnets. One would use these discs to prevent ferrous metallic items from being drawn to the magnet, or to prevent accidentally magnetizing nearby metal items like tools & fasteners.

This explains the brass content. The plating is likely a harder non-ferrous metal intended to protect the soft brass against wear & tare. Just an assumption.Decades away from full-beard growing abilities.

-

09-23-2016, 07:29 AM #76

You can't "scrounge" every part...

You can't "scrounge" every part...

As I formulated the bicycle sawmill contraption, I foresaw the possibility that scavenging every part for it might not be completely feasible. Either due to usable lifespan of the part, or the fact that some things just do not survive replacement.

Like bearings (rolling-element bearings). I can't scoop up some spent bearings from work, for a couple of reasons. First: being a mostly metal component, they get sent out with the other junked metals for recycling. Second: when maintenance has to replace a bearing, they are not gentle. Like the time I watched them use a cutting torch to free the shaft for a conveyor belt, from the bearing. Yes, like slicing a pie, they cut up the bearing with fire because either the bolts were giving them too much trouble, or the bearing was just too tight around the shaft. The repair, btw, was to replace worn cogs that move the conveyor belt; the bearing was just collateral damage.

So, where would I look for cheap bearings?? Not that they are cheap, but the Grainger we had locally closed about a year or two ago. Can't think of any other places locally that would have/specialize in this sort of thing . Since this won't be a "high intensity industrial" application, I'd probably be alright with a cheap Chinese made bearing. As long as it rolls smooth! Oh, and pillow blocks?

. Since this won't be a "high intensity industrial" application, I'd probably be alright with a cheap Chinese made bearing. As long as it rolls smooth! Oh, and pillow blocks?

Hmmm... *falls down another rabbit hole*

So, I guess, commonly pillow blocks already come with bearings. The bearing is a given by that point, so I wouldn't need to order the two separately. Kinda like ordering a couch: it automatically comes with cushions. So, I think pillow blocks would better suit my needs than just bearings lol.

Next item: tachometer/rpm meter. Completely optional, but it would thoroughly tickle my statistical curiosity! I've found what may be my best option for this.

https://www.amazon.com/gp/aw/d/B0153...=IY188XXFWETCW

So far, any bicycle "multifunction computers" I've seen start at about $20. And they don't mention having an rpm readout. Six ways to slice, dice, and display speed? Yes! But no RPMs lol.

I'm open to suggestions! There may be suppliers of industrial machinery that would have a similar product for less money? I have never needed a list of suppliers for things like that, so I don't know. I also looked on aliexpress, and found some tach's for about half the cost, with free shipping. But... I haven't heard a lot of good things about that site .

.

Maybe I should look at The Bay, while I'm looking at Amazon. Couldn't hurt, I guess...Decades away from full-beard growing abilities.

-

09-23-2016, 03:14 PM #77

Wanna look at bearing?

McMaster-Carr

McMaster is fast and has an asinine amount of stuff, however they can be on the pricier side of things.

Mounted Bearings & Pillow Blocks - MSCDirect.com

MSC is similar, might have better pricing.

https://www.thebigbearingstore.com/p...lock-bearings/

Never heard of these people, but could be good.

A lot of the bearings that you are looking for are going to be made in china. The tolerances and materials required are not that demanding.

As far as the RPM thing goes, I would assume a standard speedometer for a bicycle would work? I don't think they run very high when having limited bells and whistles. Might have to convert MPH to RPM's though.... However, you'll have to run calcs to get the true RPMs of the blade versus the powering bicycle wheel. At the end it would just be a number to multiply the RPM value of the powering wheel.

-

The Following User Says Thank You to dinnermint For This Useful Post:

Crawler (09-23-2016)

-

09-23-2016, 03:32 PM #78

I might also recommend McMaster Carr:

McMaster-Carr

cheaper....McMaster-Carr

Since you are going to be low speed the pricing would be a lot better.

I might use cast pillow blocks for the arbor itself and the actual pedal mount but a unit from a bike with long pedal arms welded to a plate would suffice for your usage.

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

Crawler (09-23-2016)

-

10-07-2016, 05:26 AM #79

I've been spit-balling again, on the backburner, about framework materials. Ideally, I'd scrounge for it. But, in keeping my options open, I've looked into things that can be bought.

Would you guys think T-posts or U-posts would be an adequate substitute? I'd bolt them together, with whatever amount of overlap is necessary to get the correct strength & rigidity to the frame. Holes drilled where appropriate.

Everbilt 3 in. x 3 in. x 6 ft. Green Metal Heavy Duty Fence U-Post 901156EB at The Home Depot - Mobile

Everbilt 1-3/4 in. x 3-1/2 in. x 6 ft. Green Steel Fence T-Post 901176EB at The Home Depot - MobileDecades away from full-beard growing abilities.

-

10-18-2016, 11:25 AM #80

Cabin fever!!!

Cabin fever!!!

Only 70 degrees out, and I think I'm already going stir-crazy! But at least the other room is starting to resemble some place I can do hobbyist & handyman stuff. Right between the L-shaped computer desk, and the futon we have for when guests need to crash!

Having finally laid eyes on the carpet for the first time in months, my brain started to have "thought diarrhea". And then, after a night or two of playing "connect the dots" with parts in the two boxes of random metal from an estate auction, I decided to organize them a bit.

The items pictured are mostly relating to the human powered saw idea, plus a few odds & ends that caught my eye as my A.D.D. meds wore off while sifting through the boxes lol. They are organized by sizes smaller to larger, left to right as well as bottom to top, depending on what was measured (inner diameter or outer diameter).

The pulley at the top was already on the shaft, along with the collars & bearings. The pulley right below that has a silky smooth bearing already mounted in it.

Here is the result of playing "connect the dots"...

A couple points of clarification:

The pillow blocks are plain sleeved, 0.75" ID. Brass?

The rods, lower middle (vertically aligned), are tube-stock. Top middle is solid bar stock, horizontally aligned.

Some of the collars (bottom right) are lacking the tapped hole, and associated allen bolt.

This week, I'm gonna glue a few pieces of pallet wood together, cut into a circle, and add a couple pegs of whatever suitable material I can come up with. Then, it's just a matter of putting a groove into the circumference, followed by mounting it!

Hmmm... after running a "mockup" in my head, physical impossibilities shot holes all through having a couple pegs as pedals. They would intersect the stand holding it up. Gonna have to do a crude replication of a bicycle crankshaft (see: Z-shaped crank). Still, mostly wood.

Why go through the trouble of this half-measure of making my own crankshaft & drive wheel? Especially when it's basically a practice run for the full project?? For one thing, it's kind of driving me nuts to have this idea sitting in limbo! For another, I can't fit my bike in the office. And finally: I still don't have anything to build the frame for the "sawmill" with!!

"Soon..." *taps fingers together like an evil genius* "Soooon!!!"Decades away from full-beard growing abilities.

79Likes

79Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote