Results 31 to 40 of 80

Thread: Conundrum Curiosity Complex.

-

02-29-2016, 03:04 AM #31

Oldie but goody...

Ed

-

02-29-2016, 05:25 AM #32

Wow, that was a joy to watch. That man has the skill of five hands...

I find it funny that my wife calls ME "monkey feet" because when barefoot at home, I often pick up trash that hass fallen to the floor woth my toes. It's easier than bending over.Decades away from full-beard growing abilities.

-

02-29-2016, 06:27 AM #33Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I know you are trying to think out of the box, but what is wrong with hand tools, folks have been using them very successfully, for years…

Or instead, using a bike, sun or wind, to charge batteries and running an electric motor driven saw… on batteries.

Sometimes it not how high you climb the ladder, it’s putting the ladder on the right wall.

-

02-29-2016, 12:03 PM #34

All fair points. But I have a few worth repeating. I don't have an electric motor driven saw. I also don't have a way to cut something length ways, effectively. I have a couple different hand saws, but no hand plane to straighten out the piece once I cut it. A hand cut board would lack a finished edge... a properly straight line. I don't shave with a SR because I hate precision, after all

.

.

Figuring out ways to "make do" has become fun for me. May have been developed out of necessity, when it was known as "getting by" during my impoverished childhood. Yet another mental survival tactic. (Kinda how a random person in a public place can sense that you are making eye contact with them, even if they are in a conversation.)

Back on topic. A circular saw doesn't have a heavy flywheel... time for more web-fu.Decades away from full-beard growing abilities.

-

03-02-2016, 10:57 PM #35

After talking to the maintenance supervisor, I won't be able to avail myself of the scrap metal. Sadly. Apparently, it stems from an incident at one of our Michigan plants. Some folks were stealing scrap, and a security company was brought in to figure out who. All because of some bad apples.

On the way out last night, I asked him about belts. "So the v-belts, like on the lid line. What happens to those when they are spent? Thrown out, in the trash?" M.S.: "Yep." Long story short: I can have a couple the next time they have to throw some away, but I should tell him first, so nobody thinks I'm stealing lol. I'll mention this to some of the maintenance crew, to maximize opportunity across shifts .

.

In the meantime, I think I'll post some ads on Craig's List for "Wanted: bed frames, other metal stock". State that I'll haul away unneeded metal for free. Maybe mention the project, so they know I'm not just tryin to hawk it at a scrap yard.

Time to work on some concept sketches...Decades away from full-beard growing abilities.

-

03-03-2016, 12:32 PM #36

have you tried your local scrap merchants, they will probably sell odds and ends for a little over scrap value, also fabricators etc might have stuff suitable in their scrap bins, even exhaust places might have old exhaust systems that you could utilise.

Bread and water can so easily become tea and toast

-

03-04-2016, 11:37 AM #37

Doodle Time! Can't Touch This...

Doodle Time! Can't Touch This...

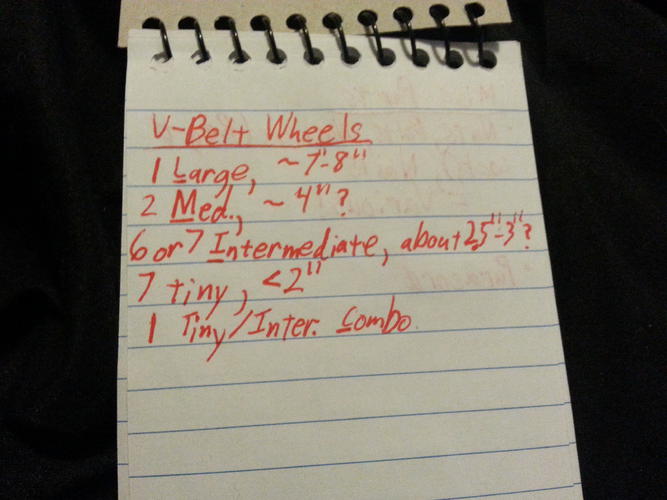

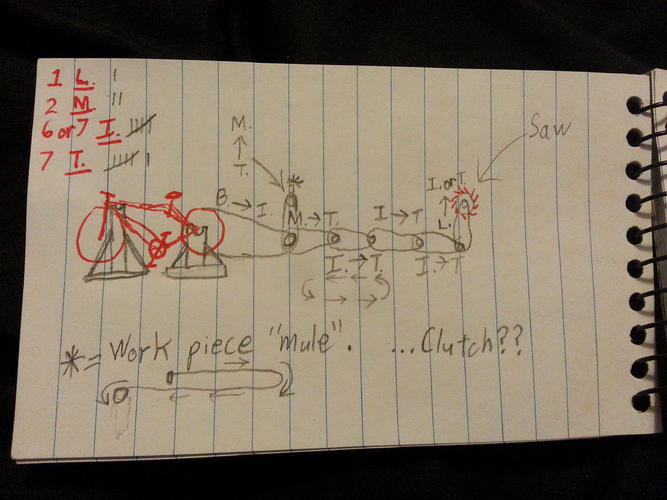

So here is a very rough, first draft, sketch for the concept of the of the drive system. Also, a quick reference key for the "brainstorming level" quality of drawing.

Sorry for my handwriting; it was done between machinery jams at work...

The above inventory was assembled from the pics I took & posted here, of the pulley wheels. Took a couple quick measurements tonight. They all seem to have a groove of a half-inch, give or take 1/16th". Also, diameter of the largest is 7".

The letters all over it was me attempting to keep track of wheel size stepping up or down . It's rough. It's not a complete blueprint. But it does feel better to get some of this clutter out of my brain... sort of.

. It's rough. It's not a complete blueprint. But it does feel better to get some of this clutter out of my brain... sort of.

Got a couple pieces of plywood that I'll spray with clear sealer (for slickness) for the tabletop. Junked pallets for the pusher block on the "mule". I've got an idea for... braces? They would be wood with plastic runners, hold down the workpiece from above, parallel to the blade, anchored off the sides, and adjustable both vertically & laterally. More sketches to come...

As always: question or comments are more than welcome!!Decades away from full-beard growing abilities.

-

03-04-2016, 12:09 PM #38

Slightly random, related thoughts.

Slightly random, related thoughts.

One website that I dug up some info on...

900mpg : Building an Electric Bike

It really helped with some curiosities I had about RPMs in regards to bicycles. It also explained the math behind it good 'n proper.

Again, I was at work, but I crunched some quick numbers after reading that article. It's entirely possible that I'm wrong, and my wheel diameters were estimates. Based on a bike's wheel RPM at the wheel for 20 mph (a sustainable pace for me on level terrain & light winds), rounded down to 250 RPM, putting in the number of steps (belts), I came to an RPM of over 5,000 at the saw. Again... that's if my slap-dash math was in the neighborhood.

Did some self education on flywheels.

https://en.m.wikipedia.org/wiki/Flyw...rial_selection

Which brings me to my next question! Anyone happen to know the "burst velocity" of a regular steel, or carbide toothed circular saw blades (the usual 9-10 inch size)??!? I extremely doubt that I will reach the blade's burst velocity. But when "Tim Taylor-izing" a bicycle to rip through lumber, with little safety precautions beyond common sense, I'd rather be safe than sorry! I wonder how an email posing such a question would be received by the likes of Black and Decker, or Skil? I expect a response full of "...due to patents, etc...".Decades away from full-beard growing abilities.

-

03-04-2016, 06:01 PM #39

So, I found something interesting and think it will be quite useful. I was thinking about actually attaching the v belt wheels to the frame of the bike. Something clamped on there with bolts and I came across this in a thread on B&W photos.

http://straightrazorpalace.com/attac...remouleur4.jpg

it won't let me attach the photo, so here's a link instead...

Shouldn't be too bad to build a platform and replace grinding wheel with a saw blade....Last edited by dinnermint; 03-04-2016 at 06:03 PM.

-

03-04-2016, 07:31 PM #40

Not exactly sure of the "burst velocity" of circular saw blade, but I do have access to a 5 HP 12" table saw that runs fine through just about anything, including nails, at 3500 RPM - that's around 180 ft/sec. As long as you stay below 1000 ft/sec (19500 RPM on a 12") you should be fine. With a bicycle drive, you will probably on get around 1000 RPM.

Why 1000 ft/sec max? Speed of sound is around 1200 ft/sec and the air around rotating parts starts doing freaky things around that speed. Just accept the "freaky things happen" and don't go down that rabbit hole. Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

-

The Following User Says Thank You to criswilson10 For This Useful Post:

Crawler (03-04-2016)

79Likes

79Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote