Results 11 to 20 of 80

Thread: Conundrum Curiosity Complex.

-

02-26-2016, 07:30 AM #11

Anything human powered is going to be fractional horse power. A person can manage one or so hp for short periods, but you won't be able to do anything else while putting out that much power.

-

02-26-2016, 08:12 AM #12

That doesn't sound like much of a can-do attitude! And if I had a formal education in this sort of thing, I could more adequately explain why I think this is feasible.

Just break down how a bicycle can get a human being moving so fast. Pedals turn a sprocket that turns an even smaller sprocket attached to a big wheel, moving really fast! No remove the wind resistance, and some of the friction (until you begin to cut, that is...) because you will be mounted on a stationary contraption with lubed up at all the necessary places.

Decades away from full-beard growing abilities.

Decades away from full-beard growing abilities.

-

02-26-2016, 10:02 AM #13

And your blade will effectively be a wheel, with the work piece as a brake.

High rpm with low torque won't be terribly effective I don't think.

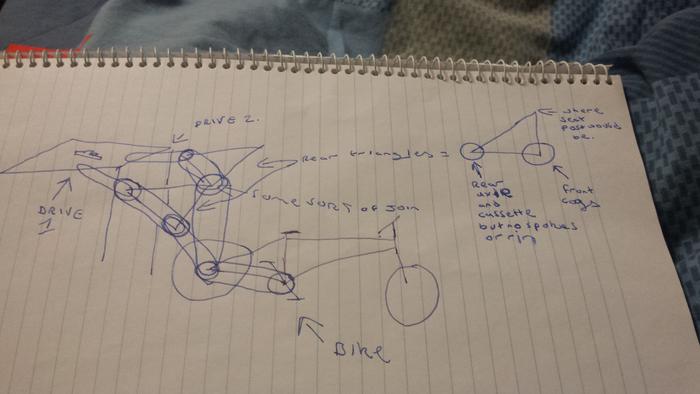

If I was going to do something like this I might use one bike as a power plant and run chains from the rear cogs to the front cogs of 2 other bikes, assuming 21 speed bike used as the main drive one rear cog would be taken to drive the rest of the cassette and then the gearing for the other 2 could be fairly adjustable using the gearing the bike comes with to drive another chain to the motor, a drive belt around the rim or even direct friction drive from the Tyre.

I would probably just saw off the rear triangles of the driven drive trains and fit the rear gear lever to what was left of the frame.Bread and water can so easily become tea and toast

-

02-26-2016, 11:10 AM #14

I thank you for your input! But, dear sir, I fear you may need to provide a napkin drawing (rough sketch) of what you have just described. It could be the late hour; or you may have neglected a step or two (likely obvious to you), leaving me unable to connect the dots

.

.

And now for some pics. Took me a few minutes, but I think I dug them all out of the "box lot" I won them in...

On second thought, it won't upload any pics. Maybe I'll reboot the router & try again in the morning.Decades away from full-beard growing abilities.

-

02-26-2016, 01:52 PM #15

Something like thisBread and water can so easily become tea and toast

-

The Following User Says Thank You to edhewitt For This Useful Post:

Crawler (02-26-2016)

-

02-26-2016, 03:08 PM #16

VFD= variable frequency drive, basically adjusts the power being sent to an electric motor, this adjusts the speed.

This are interesting concepts, but I think you can make one better.

Yes, triangles are the strongest shape, this is why most structures that utilize a vertical rectangle has gussets in the corners. Welding is usually preferred and a quick way to a stable structure. That's not to say you can't make a stable bolted structure, but it isn't always easy. There's inherent "slop" in each and every bolted connection, so that you can slide the bolt through the hole. Just something to bear in mind in the development and construction phases. If it's wobbly you at least have an idea of the issue, so that you can develop a proper solution

I don't see why they wouldn't. Recycling places pay by the pound and companies usually stock up until they have enough to pay for transport at a minimum. You would, at the very most, be swiping 15-20 pounds of steel. That's probably pennies. I'd keep a lookout for anything in the 1-1/2" to 2" range. Thicker than what you need structurally speaking, but give you enough wiggle room for alignment, however you adhere the pieces to one another.

As far as horsepower is concern, it shouldn't be too much of an issue. I'm assuming you're not going to use this to cut a few hundred pressure treated 2x4's? If you can produce 1/4 to 1/2 horsepower for small scale with a sharp blade, that should be sufficient.

I will think on this further, definitely interesting

-

02-26-2016, 03:11 PM #17

-

02-26-2016, 05:02 PM #18

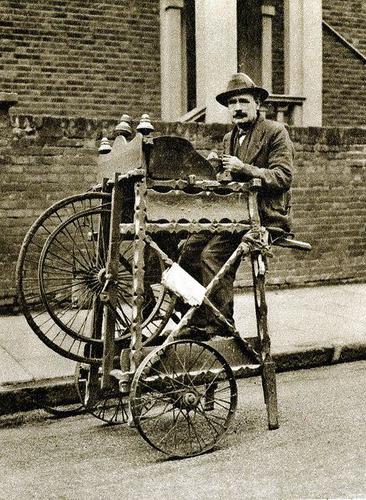

Nothing new under the sun...or.... am I wrong?

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

02-26-2016, 07:44 PM #19

I think completely unique inventions have become fewer and fewer inbetween. But, I believe that is more because we have already solved almost all problems. Most problems that persist do so because of limitations in our capabilities. With those, it's really just redesign and improving efficiency...

-

02-26-2016, 09:16 PM #20

Amazing! I learned something today. the second video didn't seem to have any kind of fly wheel at all. (i still think i'd use one so i could coast every once and a while though

).

).

79Likes

79Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote