Results 41 to 50 of 80

Thread: Conundrum Curiosity Complex.

-

03-05-2016, 02:52 PM #41

If by burst velocity you mean max RPM a cutting wheel can operate at safely, all cutting discs/ blades have their max RPM on them as far as I am aware.

Bread and water can so easily become tea and toast

-

03-05-2016, 11:15 PM #42

-

03-05-2016, 11:59 PM #43

It is true that most cutting discs/blades state a recommended max RPM, but this is not what I was referring too.

https://en.m.wikipedia.org/wiki/Flyw...rial_selection

In a nutshell, Burst Velocity for a spinning part refers to the angular velocity (RPMs) at which the disc starts to fly apart. So, it spins so fast that the centrifugal force surpasses the tensile strength of the material.Decades away from full-beard growing abilities.

-

03-06-2016, 05:25 AM #44

Alright, that's it. I can't stand it anymore. What are these "freaky things" you speak of? Got a nutshell example for us??

I tried to heed your advice & stay away from that rabbit hole. But it's sucking me in like a super massive black hole. And my web-fu was no help... are you sure about "1,000 fps"?Decades away from full-beard growing abilities.

-

03-10-2016, 04:43 AM #45

Roughing one out...

Roughing one out...

I don't plan on actually holding the workpiece myself. I've got a concept cooked up to hold the workpiece down, and a pusher block/bar would be winched across the cutting table (pulled by a v-belt, "geared-down"; reeled in by a yet t.b.d. method). Moving on...

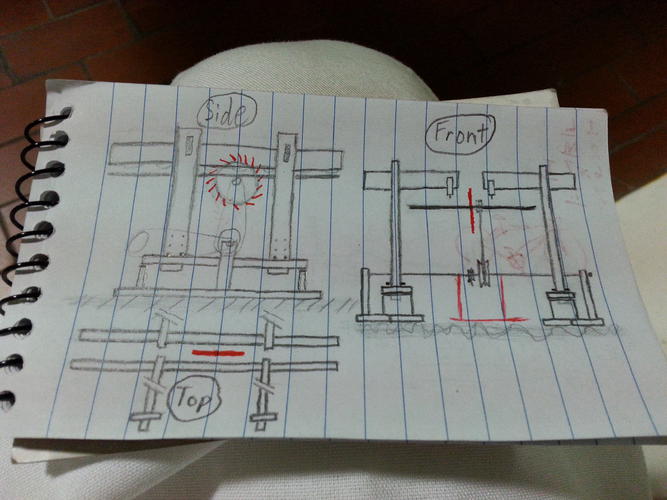

I took some time to rough out a sketch of the above mentioned concept, meant to brace the workpiece. What follows is that sketch, done entirely free-hand on a small memo book, with my knee as a drafting table. I hope it is comprehensible enough.

A few things to keep in mind, regarding this sketch. It is not exactly of proper scale, or proportions. It was designed with the intention of using free, usable condition, junked wood pallets. The framework for the drive train will be metal (represented above by the red bit in the lower right corner). Slick plastic runners (work trash, conveyors glide on top of them constantly) will be mounted on the underneath side of the bracing members so as to not impede lateral movement.

Not shown, but will be part of the table: supports for the table itself, as they would likely be independent of the brace framework, but part of the drive train framework. And the workpiece "mule" (and pusher block) that would winch the piece. Those are less structurally complex than this brace. This brace was also designed to be adjustable both vertically and horizontally.

That was invigorating, challenging, and entertaining to put to paper !

!

And Mr. criswilson10: Still waiting for an answer on those "freaky things"?!Decades away from full-beard growing abilities.

-

03-10-2016, 05:12 PM #46

As far as speeds over the speed of sound, some interesting things happen. However, most of those are only realized in jets. Without doing my own calculations and going off of the 19,500 RPM on a 12" circular saw, you would be running the blade at almost 4x the recommended speed.

I can only relay information that I was given or watched on the TV back when Discovery actually had informational shows. Particularly with the SR-71 plane. The frictional forces from air become so great, that heat expands significantly. I do believe to the point that they had to run cooling throughout the leading edges of the plane itself so it wouldn't melt mid-flight. As far as freaky things, air flow is determined by how air moves around an object moving through air. This is typically achieved with what is called boundary layers in fluid dynamics. This is basically a calculus based model that shows the influence of the air in contact with the object moving and the stead-state air that is not influenced by the object itself. IIRC, the math behind boundary layers at "normal" speeds breaks down once you reach supersonic speeds. Also add into the issue that a supersonic wind tunnel doesn't exist. As a result, modelling the influences of the air around an object at those speeds has been done in trial and error over the past decades. I could write more about it, but that would make this forum a textbook and you guys don't pay me enough for that

-

03-21-2016, 11:11 AM #47

On the 5th, I tried to e-mail two companies that I could think of making circular saw blades, off the top of my head. I will paste my message to them here.

Sent to Skil tools.

Black and Decker gave me an error message.

Gonna look up some other big names later today at Home Depot.

I think that was fairly concise & to the point, without going into lengthy detail. I know that there is often a limit placed on the length of messages placed through "contact us" forms, which might explain the error message I got from the Black and Decker website. Any ideas on how I might modify that message??Hello!

I did not (nor did I expect to) find the answer to a question I have in the FAQ's/search function. It certainly is not a common question. The answer I seek would likely cone from your R&D department.

First, what prompted the question. I am basically MaCGyver'ing together a bicycle/human powered table saw. Using v-belts and pulleys, I will step up the RPMs high enough to compensate for the lack of horsepower that would normally be provided by a DC motor. Because I'd rather be safe than sorry...

What is the burst velocity of your co.'s circular saw blades (7.25"-12")?? I don't need patented information, etc. And I EXTREMELY doubt that I will reach such a high RPM. I would simply like to know what ballpark (narrowed within 1,000?) of RPMs to keep the saw blade under.

For reference: https://en.m.wikipedia.org/wiki/Flyw...rial_selection

I know this is an odd question, and I don't expect an immediate response. I also waive your company of any and all liability related to this endeavor of mine.

I look forward to your thoughtful response!Decades away from full-beard growing abilities.

-

03-21-2016, 12:30 PM #4850 year str. shaver

- Join Date

- Aug 2008

- Location

- Pothole County, PA

- Posts

- 2,258

- Blog Entries

- 2

Thanked: 522

How about a hand written letter to the different companies. No possibility of message error there.

Fire away!!!!! The USPS won't fail you.JERRY

OOOPS! Pass the styptic please.

-

03-21-2016, 02:46 PM #49

I would just see if you could cut stuff staying within the maximum velocity that is provided on the blade itself. Most likely, the engineers will just give you the labelled number or tell you to look at the blade. A physical letter will get their attention.

Typically, all numerical limits will have in a built-in safety factor. It is unlikely that anyone in the company will willing give you information to exceed a specified recommendation/reduce that safety factor that would put their company and job at risk.

-

04-27-2016, 02:30 AM #50

The pedal powered table saw/sawmill is currently in a holding pattern. I've managed to grab two v-belts thrown out by maintenance (and a third that will require repair before use), but none of these are long enough to fit around the wheel of a mountain bike. I suspect that the pair long enough for this will be worn enough for replacement sometime in the next two months

?

?

My next hair-brained idea: welder's chalk (soapstone)/school chalk as a honing aid.

Why? Because I've only got two stones: a Shapton M5 12k ceramic, and a two sided utility sharpening stone (every bit as old as me).

The first couple razors I honed were done exclusively on the 12k... it took weeks. With the fixer-uppers I've scooped up for reasonable prices, I've been playing around with the utility stone. Things like chip removal, finding "good steel", or trying to get the bevel close on a near wedge that was butchered with an amateur regrind.

I found a couple threads that state chalk (among other things) was used as a mild abrasive for strop treatment. My idea was to use the extremely soft stone to, at the very least, slightly clog the low grit utility stone... trying to bridge the gap from the 200-400~ish range to my 12k ceramic.

Though the thought has crossed my mind, I shant use the welder's chalk as a slurry stick to build a slurry on the 12k, as that hone is slow enough the way it is.

The soapstone doesn't really go on evenly, regardless of whether the stone is dry or wet. But if it is wet, it is a simple matter to use your finger to rub it in until there seems to be an even consistency. Rubbing it in with your fingertip also gives you the chance to feel for an overly large granules or foreign particulates.

I'm still playing around with this concept, as I work out some minor chips in blades.

How about the rest of y'all?!? Got some kooky idea you would like to share? Or something ya need help brainstorming on?Decades away from full-beard growing abilities.

79Likes

79Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote