Results 71 to 80 of 91

Thread: Disinfecting / Sanitizing

-

12-01-2019, 06:18 PM #71

Hi Mike,

So, can you explain a bit more how you drill off the heads of the pins with a drill?

Do you use a full size drill or a dremel?

I have a Dewalt battery drill/screwdriver, will that do the job? It feels pretty big for such a small job.

I have a Dremel somewhere that might be a better size if it can be done with that.

What size drill bit do you use, and how do you stop the drill slipping off? Tape over or around the pin? Looks like a 1/16.

Also, where do you get the brass rods (pin material) and washers etc?

Last question Mike.

Where do you get the scale material and do you make them or buy them pre made?

Thanks.

Steve- - Steve

You never realize what you have until it's gone -- Toilet paper is a good example

-

12-01-2019, 08:43 PM #72

Hey, Steve. Sure, no problem. Let's start with your last question. As for scales, I prefer to use the original scales.

I've bought many razors that have a busted scale, and good blade, and some with junk blades and good scales, so I have a small cache of scales to work with to make a set from. I've also been gifted scales ,or materials to make them from. Most of my scale making, is with wood. Not that I can't work with other materials, I just love the different patterns that the grain in wood, reveals. It can't be duplicated, and each 1/8 inch cut reveals something different. Then the coats of Tru-Oil bring it to life.

I've also have stores that I can buy some exotic woods from, and I'm only 5 miles from America's largest hardware store. ( Hartvillehardware )

As for removing the pin...

File a flat spot on the pin head, then I use a pin vise with a 1/16 inch, centering drill bit, to mark the center as close as possible with a few twists from my hand.

Then I use a cordless screwdriver that has a 1/4 inch chuck, and use the 1/16 drill bits that have the 1/4 inch lugs. Using light pressure, I'll drill a few seconds and check with my magnifying glass to make sure I'm staying centered.

Keep drilling and checking your staying centered, and the next thing you'll know, is the collar is spinning on the drill bit. Make sure the pin isn't flared, or has a burr sticking off of it, before you push it out. Make sure to support the opposite side of the scales from what your pushing.

My screwdriver is geared pretty slow, maybe 60 rpm. Its slow, but I'm not in a rush, its about keeping them as original as possible, for me. Only substitute when all options are gone, or I should say...have rotted away.

You can also use a dulled DE blade to protect the scales when using the file method.

Last edited by outback; 12-01-2019 at 09:09 PM.

Mike

-

The Following 3 Users Say Thank You to outback For This Useful Post:

randydance062449 (12-02-2019), ScoutHikerDad (12-02-2019), STF (12-01-2019)

-

12-01-2019, 09:15 PM #73Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I do like Mike, except I punch a center divot on the flat, with a small 1/8 in Philips screw driver. that I sharpened and hardened. Pins are soft so it does not need to be that hard.

I start the hole with a 1/16 in single flute, center drill bit, then drill with a sharp 1/16 in drill bit, center drills are cheap and so are1/16th in. drill bits buy a bunch.

I do lite taps on the drill press with a wood backer block with a divot for the back pin, don’t drill the divot in the wood too deep so it will keep the pin from spinning while under pressure. Drill at the slowest speed.

Just a few taps and you are done, pin vise also works quickly, with a sharp drill bit.

Lift the scale off the drilled pin, do not try to punch it through. If the pin is bent, you will blow out the back scale. If bent lift off the blade and cut the bent pin off to remove from the back scale.

I have a tin of collars but usually make new, doming Micro Fastener washers.

-

The Following 3 Users Say Thank You to Euclid440 For This Useful Post:

ScoutHikerDad (12-02-2019), Steel (12-01-2019), STF (12-01-2019)

-

12-01-2019, 10:02 PM #74

Hi,

Stupid questions probably but I'm more drywall and less fiddly until now.

"I punch a center divot on the flat, with a small 1/8 in Philips screw driver. that I sharpened and hardened."

Is there any reason I can't use a small center punch?

"I start the hole with a 1/16 in single flute, center drill bit, then drill with a sharp 1/16 in drill bit"

What is a single flute center drill bit? I thought a metal drill bit is a metal drill bit.

What is a doming Micro Fastener washer?

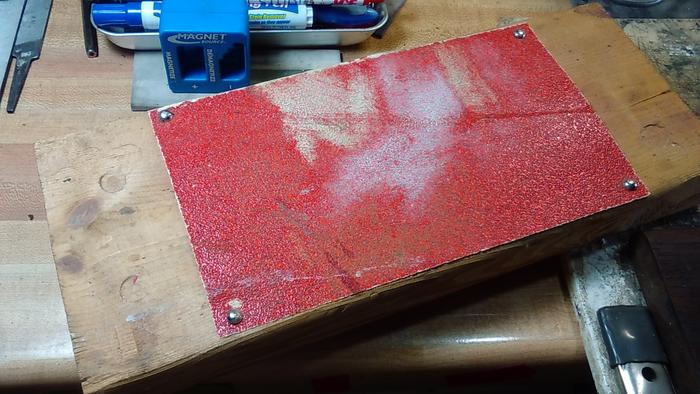

What are those things in the pic?

Thanks

Steve- - Steve

You never realize what you have until it's gone -- Toilet paper is a good example

-

12-01-2019, 10:26 PM #75

Hi Mike,

I don't have a drill as small as yours and I can see now that my Dewalt is going to be too big.

Is that file a very fine one?

Is there any reason that I cant use a dremel to drill?

I know where I can get exotic wood too, although I think Walnut or Maple might look nice.

Can you get little thin pieces or do you have to get a length like 1x1x6 and cut it to fit somehow?

I don't have a lot of little tools and can't get belt sanders etc yet.

I do have a table saw and a chop saw and an angle grinder I might be able to use but I would have to do some thinking because like I said, those are full size tools.

Where can I get hardware? Brass for pins and washers if needed?

I would also like to source horn and acrylic.

I have found some on Etsy but the seller say's they won't be big enough. I don't understand why. Unless they aren't thick enough.

What do you think?

https://www.etsy.com/shop/WoodAcryli...on_id=18474879

Steve- - Steve

You never realize what you have until it's gone -- Toilet paper is a good example

-

12-01-2019, 11:51 PM #76

Don't see why the dewalt won't work, I've used a drill press as well. I know one guy who uses the dremmel press, he likes it. I like the screwdriver, so I don't have to run in and out of the house.

The file is a fine tooth, yes.

I can get some pieces already cut, and some pieces small enough I can cut, but not over an inch thick.

No belt sander.!? Me neither.. Here's mine, a piece of 60 grt. sandpaper, thumbtacked to a hunk of 2x6.

I get my brass pins and washers at my local hardware store, in the micro fasteners section of the but n bolts isle.

The eBay stuff, is for pen blanks. Its not big enough.

Sucks, cause I can get those locally, as well.

But they could be used for a "SHORTY" project.

Yeah, I know.....what's a shorty project. It's about taking a broken razor and making it usable again.

Mike

Mike

-

The Following 3 Users Say Thank You to outback For This Useful Post:

randydance062449 (12-02-2019), ScoutHikerDad (12-02-2019), STF (12-01-2019)

-

12-02-2019, 12:05 AM #77

Perhaps these will help in your search for supplies.

Microfasteners carries a good selection of Brass and Stainless Steel washers that can be used for making or repairing scales:

Brass

https://www.microfasteners.com/home.php?cat=658

Stainless Steel

https://www.microfasteners.com/home.php?cat=657

You want the #0 washers

This place carries many different products that can be used for making scales. This link is to wood blanks that for a small fee can be cut down to 1/8 + or - for you.

Wood

https://www.woodturningz.com/Wood_Spindles.html

They will also cut down any of the acrylic blanks that they sell.

I do hope that these links will be of some help.Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following 4 Users Say Thank You to cudarunner For This Useful Post:

outback (12-02-2019), randydance062449 (12-02-2019), ScoutHikerDad (12-02-2019), STF (12-02-2019)

-

12-02-2019, 12:47 AM #78

-

12-02-2019, 12:56 AM #79

It's been quite awhile since I've purchased nickle silver rod as I bought a Bunch.

I believe that I got my nickle silver here:

https://www.texasknife.com/vcom/prod...af2ce416b806b1

They also carry brass.

With that said--I buy my brass rod locally at an Ace Hardware.Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

12-02-2019, 03:24 AM #80Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

“What are those things in the pic?”

It’s a single flute centering bit.

A sharp long point is easier to see the tip and make your starting dimple in the center of the pin. A Larger center punch, may be hard to see the center of the pin. If it is not in the center, you will have to file off more pin and try again.

Any knife supply will have scale material and pinning material, washers from micro fasteners can be formed, domed on a domming and dapping block.

I like Texas Knife supply and Jantz for supplies and Masecraft supply for some scale material.

There is a lot of information in the library on un-pinning, pinning and scale making. There is also a great horn scale making tutorial, step by step by Karlej.

Horn is an excellent material to learn on, it is easy to work with hand tool, inexpensive and looks great with just a little sanding and polish.

-

The Following 2 Users Say Thank You to Euclid440 For This Useful Post:

outback (12-02-2019), ScoutHikerDad (12-02-2019)

255Likes

255Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote