Results 41 to 50 of 90

-

04-27-2020, 02:35 PM #41Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

The last 2 days have been a bit slower progress. Both days have been spent on large files. A total of approx 40+ more are now finished.

I now have 2 different scrapers. A brass rod scraper and a copper pipe scraper. They both do an excellent job. I will be constructing a brass tube scraper from a 9mm shell casing in a few days. A friend will donate a few to me for that purpose. I have also learned that the corner of the scrapers will act as a pick to remove the "pins" that are stubborn.

Due to the volume of files I will leave the scraper's for later use unless the file I am working on is really gunked up. I am pretty sure that most old files that have been rusted and put into a vinegar bath would benefit from the use of a scraper to remove not only the built up gunk in the gullets but also the oxidized steel.

The big take away from this is that an old file can be brought back to life with a bit of work. It is rather satisfying to take something old, tired and dirty and make it come to life again.

About 50% done now.Last edited by randydance062449; 04-27-2020 at 02:42 PM.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

The Following 2 Users Say Thank You to randydance062449 For This Useful Post:

Geezer (04-27-2020), ScottGoodman (04-27-2020)

-

04-28-2020, 12:42 AM #42

Randy-I think you win the contest for "piles of files." I think this huge haul of treasure is just karma coming back around for all the people you have helped and mentored over the years. Enjoy once you get them cleaned up.

There are many roads to sharp.

-

04-28-2020, 03:12 AM #43Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Today very little was done with the files. I had to drive to Doc"s workshop and unbolt his vise and buffer. Sounds simple but the vise was where Doc would epoxy up the handles on his knives and also where he would solder on the guards. Guess what, some of the epoxy and some solder dripped down onto one of the bolts screwed into his workbench! It took a fair amount of effort to get that nut loose and off the bolt!

Also picked up the quenching tanks and disposed of the quenching oil. Plus 2 articulated lamps, 3 rock hound hammers, epoxy, solder wire, more wood, steel rod, my metal rolling cart, fire bricks, leather scraps, bolts for knife handles ( I cannot remember the proper names of these (barrel bolts?)), some heavy steel bases for something, piece of copper pipe, can of Brownells powder to prevent scale formation.

Next I have to go back and take one of the metal workbenches where the Wilton Square Wheel grinder and the Baldor buffer were attached. I purchased both of those from Doc a few years ago when he stopped forging. The bones in his hands simply could not take the pounding anymore. He was in his 90's.

There are 2 other workbenches but one is far to big for me. I have asked for the other one. His son will let me know. Plus the other 2 lights and maybe a few other odds and ends.

Once i got home to Wisconsin, 100 mile drive, and unloaded the stuff I sat and rested for a bit. Then I worked on 3 files that I had completed yesterday. This time I used a wire brush on them again then I took my copper scraper/file cleaner and proceeded to scrap each one. The thought was to remove as much oxidized steel as possible and get back to good steel. Then test them by filing on an old railroad spike. I would scrap one side, brush it again, then apply some chalk and test and compare each side. In each of the 3 cases the file cut better after the cleaning/scraping with the copper scraper. I did the same with the other side of the file and experienced the same improvement. In hind sight it makes sense because what I am doing is simply removing rust and other oxidized steel thus getting back to the good steel. I also noted that one flat of each file would cut better than the other side. I assume this means that one side was used more than the other side. Which sounds reasonable to me.

I will try to get some pics of this stuff and the scraper tools. I hope I am not boring you guys with this. Let me know if you have any questions.Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

04-28-2020, 04:35 AM #44Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Here is the three-cornered file that has the teeth ground off and shaped to a point. It is wrapped with masking tape as the edges are sharp. I may only sharpen about 1inch from the tip and dull the rest and replace the tape with a piece of rubber fuel line.

I cleaned it up, it was rusted and it scraps fine as it is, but will take an edge with a diamond plate, I sharpen one corner.

The scraper was in a toolbox with a bunch of hand tools and saws. The box was probably made by the owner and he took some pride in it. It is made of fur plywood, screwed together with brass screws. Note his initials by the handle and decorated with brass pins around the hasp, also note that he took the time to clock each of the brass screws around the entire box and the screws on the clasps.

I cleaned the box with mineral spirits and brushed on a couple coats of linseed oil and padded on a lite coat of shellac. The bottom was left untreated, that was what the whole box looked like.

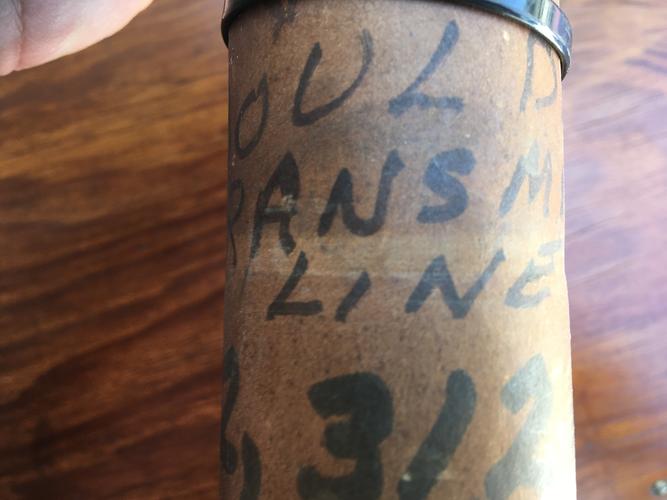

In the box with the tools was this 12-inch piece of aluminum cable, with a tag that reads, Boulder Transmission Line 2,312 MCM. The cable is about 17/8 thick, aluminum cables were/are used for high voltage transmission.

Likely this guy worked on the Boulder/ Hoover dam and carried this piece of cable in this box all these years. Clearly he was proud of his work on the dam project, it is a small piece of history.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

randydance062449 (04-28-2020)

-

04-28-2020, 05:28 PM #45Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

.

.

Euclid440 ....

Thanks for the pics in your post. They lend a lot of info to the post. I have to do more of that.

Is that scraper for removing the "pins" embedded in the gullets of a mill file? I assume so. Personally I can see the need for a smaller triangle file for that job.

I have found that using the corner of a copper/brass scraper will do the job just fine. But I will also make a "pin" remover from a small triangle file which is what I used initially.

My main concern is to clean the gullet without dulling the file teeth. That's why I prefer non-ferrous metals for that job.Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

04-28-2020, 06:33 PM #46Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

No, it is much too big for that, about ½ inch at the flats, he used it for scraping something, and judging by the tape it was for some close in work and used frequently.

It will be good for shaping horn scales.

I use a sharp pointed Exacto knife blade, pushing the blade with the flat/dull side forward between the teeth. The sharp point gets under the pinning and pops it out. It also gets between the teeth of fine files to get deep into the grove and loosen any rust.

Once the pinning is removed, a card file removes the rest. A quick hour or so dip back in the vinegar get the rest of the rust loose and a final brushing with a card file get the rest.

I use 50/50 simple green soak for the final cleaning and it also neutralized the vinegar some what, because the rust much less quickly.

Yea, the box and the cable, probably told an interesting story. I did some reading on the Boulder Project and those were some tough dudes that built that thing. Some interesting history, reminds me of the history of the railroad, the engineering and guts it took to string that line across unknown country. Just the infrastructure to keep those guys alive, fed and bedded down was a monumental project.

Several years ago, we went for a trip to Central California, were we road on one of the last working steam engines. It was a logging train for pulling the lumber out of forest. It was hundreds of miles from the ocean and I asked the guy at the museum how they got the engine and train to the forest.

He said the engine and cars came in on ship, they built a pier, lay down track as much as they had, from the ship on, several hundred feet. Assembled the engine and cars, drove the train to the end of the track, then picked up the track behind them and laid another mile of so of track until they got it to where it needed to go. Later, on another ship they got more track and eventually laid a line from the ocean to the mountains for resupply.

Makes you wonder, the state has been working on widening a stretch of freeway near by for over 5 years. Every time I go by, I see lots of guys, standing around and not a lot of progress.Last edited by Euclid440; 04-28-2020 at 10:28 PM.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Geezer (04-28-2020)

-

04-28-2020, 09:12 PM #47

-

04-28-2020, 09:26 PM #48

Yes, I do remember that engine. A retired former member here with machine repair experience, is now working part time at the roundhouse, repair facility, and that engine. They are rebuilding all the heavy machinery to be able to do most any repairs needed. Work of love and skills for sure ! It will become a museum to showcase skills that made rail transportation economically feasible.

-RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

04-29-2020, 02:12 AM #49

-

The Following User Says Thank You to thebigspendur For This Useful Post:

randydance062449 (04-29-2020)

-

05-06-2020, 01:46 AM #50Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Update ....

There are now 120+ files completed in my basement. Plus another 50+ small triangle, square, and round files that I completed yesterday. There are additional 15+ larger files that were done yesterday. Plus there are a bunch of new/very good files that I need to put away such as a set of 2" Nicholson Swiss pattern files.

I am going to take a break from working on the files for awhile.

These are conservative counts.Last edited by randydance062449; 05-06-2020 at 01:59 AM.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

448Likes

448Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote