Results 11 to 20 of 71

Thread: Hinge Holes

-

04-26-2022, 06:42 PM #11Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

The tool Outback is using is called a divider/compass.

To find the point to drill the center of the scale on the pivot end just use the divider and measure from one side of the scale to the other side. Then put that against a ruler. Let say it measures 1/2". Adjust the divider closer until it reads 1/4" according to the ruler. Now put the divider against one side of the scale. The other leg will be in the middle of the scale. Mark it and drill.

Hope this helps, Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

The Following User Says Thank You to randydance062449 For This Useful Post:

STF (04-26-2022)

-

04-26-2022, 07:52 PM #12

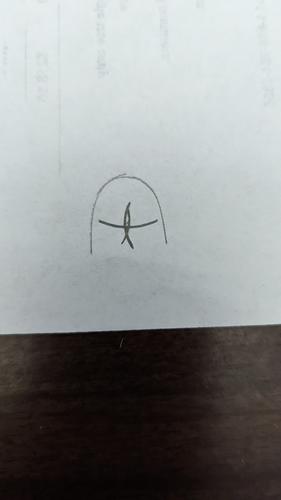

Randy kind of beat me to it. Here is a (very) rough drawing to demonstrate finding center. I couldn't find a compass so I used a pencil attached to a string. Construction workers have used a similar rudimentary method for thousands of years. The truck is to keep the measurement tool constant.

Find how far from the tip your hole should go. Measure that distance and mark it. From equal distance from either side make an arc with the compass or marking toll making sure you start from the same place on each side. A good choice is from the tip of where the downward arc meets the edge. The two lateral arcs don't even need to meet. In fact, they probably shouldn't because that leaves you a gate in between. Them. Put your mark dead center of where those two arcs meetIron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

The Following 2 Users Say Thank You to PaulFLUS For This Useful Post:

randydance062449 (04-26-2022), STF (04-26-2022)

-

04-26-2022, 09:03 PM #13

I decided to try and move this post to this a more proper thread..........

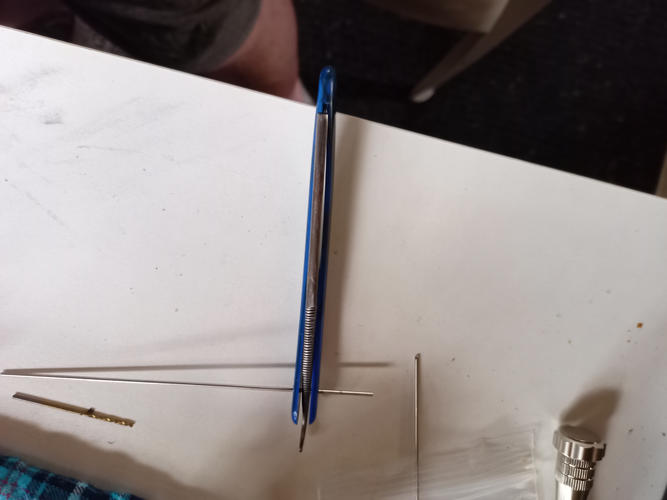

If you used a sacraficial piece between the two sides that was the thickness of the spine and any washers It would hold them aligned.

The main arguement I see to drill from both sides is so that you don't blow out the one side as the bit goes through.

-

04-27-2022, 02:56 AM #14

I always scotch-tape another scale the same width (and centered hole) to the victim and touch a drill-bit through.

Cut the tape and look. Drill it if I like it.

Lazy. Too many scales around.Last edited by sharptonn; 04-27-2022 at 02:59 AM.

-

04-27-2022, 06:04 PM #15

That is a nice idea, Tom. Good one! And if you left the extra scale on top and taped it would help to guide the bit to keep it straight.

It's just Sharpening, right?

Jerry...

-

04-28-2022, 02:22 AM #16Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

Tom is the rescale master.

It's not what you know, it's who you take fishing!

-

04-28-2022, 02:32 AM #17

-

04-28-2022, 02:44 AM #18

Hard not to do, Jerry. Lots of dusty scales in the back.

I take a matching rear scale and tape to a matching victim.

Front to back and vice-verssa. Touch the back of the victim through the pin-hole.

Untape and see if I like the position. If not, no harm done. Lots more patterns...

Then. I eyeball it and drill it from the back all willy-nilly!

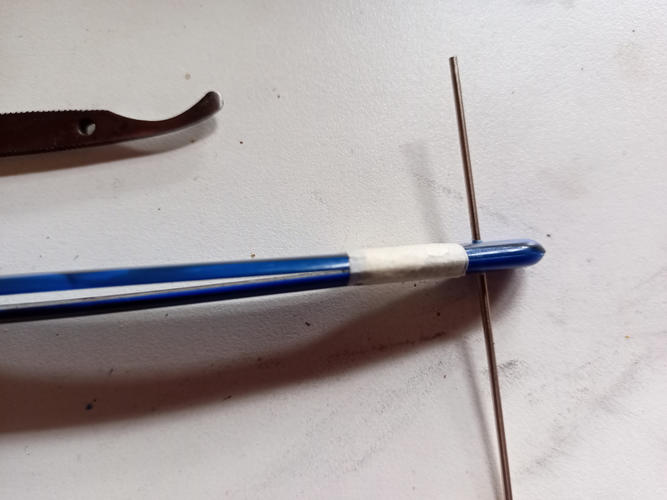

I go slow and can feel when the tip of the bit is about to break through, Flip it and go at the top as I can see it.

Then, tape this one to it's other half and drill away. Works well for me.

-

04-28-2022, 08:19 AM #19

Yeah, I've done it that way too, mainly with wood blanks I have made from snag out of the forest. If you hold your finger against where the bit will come out you can feel it about to break the surface. It's much easier.to be cavalier if they are expendable. Things that are not easily replaced or that I have more significant investment in I find I am more cautious with.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

05-11-2022, 10:02 PM #20

Guess what I did?

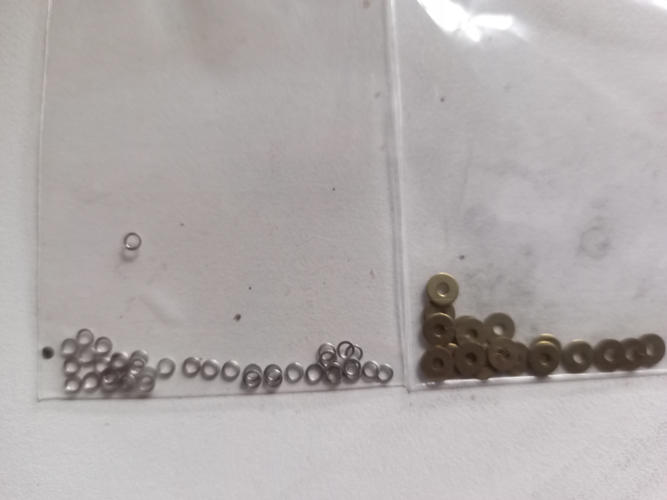

I kept losing the collars when they fell off, I must have gone through about six razors worth so I'll have to try to find the ones I lost.

I think the pin may have been too long, started with 1oz ball tap tap, forget that nonsense. 8oz claw hammer, whack wack then finish making it pretty with the 1oz.

The holes are not straight so I need a drill press I reckon, and it is nice and tight when open but goes loose and baggy when I close it again.

Practice makes perfect I know but OMG what a pita of a job. How do you guys have the patience for this stuff.- - Steve

You never realize what you have until it's gone -- Toilet paper is a good example

133Likes

133Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote