Results 21 to 30 of 161

Thread: custom ish blade blank project

-

02-26-2009, 04:46 AM #21Senior Member

- Join Date

- Jan 2008

- Posts

- 701

Thanked: 182

i have a price point i have to make and im sure that Don/Lynn also have a point of cost to return value

after all even the not greedy have to make a buck to keep things moving

im just tring to make sure i can make the sales to brake even on the first batch set up and coverign the steel stock is going to hamper me gettitn other steel and handle scales for the other side of my work

-

02-26-2009, 04:52 AM #22

i definetly interested in one what finishes do you do butch a square point 1/4 hollow with satin finish would work for me

-

02-26-2009, 05:27 AM #23

is it cheaper if the finish work is done by us as well?

engraving on flats can be done by any good trophy shop. making the jimps on a curved section is what I'm pondering. nothing irritates me more than seeing a razor that has deep jimps that are spaced unevenly or cut to differing depths. it immediately ruins the whole blade in my opinion. I'd hate to ruin my own.

Red

-

02-27-2009, 01:44 AM #24Junior Member

- Join Date

- Jan 2009

- Posts

- 23

Thanked: 2

I'd also be very interested. Maybe a square or a spanish point with a full hollow or 1/2 hollow grind? What would something like that cost?

Cheers,

Rafal

-

02-27-2009, 05:00 AM #25Senior Member

- Join Date

- Jan 2008

- Posts

- 701

Thanked: 182

i have a checkering file or 2 that i could make nice cuts across the tang with

but so far as file work that's on you all

less i get a wild hair and make up like 5 blanks as a limited thing file worked

-

02-28-2009, 12:14 PM #26

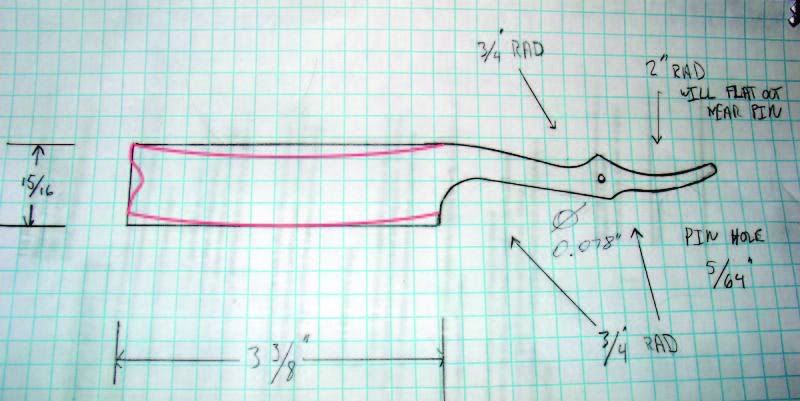

Nice sketches!

IMHO, a spanish point and a worked spine in a full hollow grind would be great.

-

02-28-2009, 12:24 PM #27

This is a great idea .Count me in. I think personally 1/4 to 1/2 hollow would be a great compromise on a wedge.

This is a great opportunity to get a cutom razor that I could put my own touches to.Paul

-

03-03-2009, 12:02 AM #28Senior Member

- Join Date

- Oct 2008

- Posts

- 110

Thanked: 21

How "blank" is this going to be? Will it need much more than a honing and scales to be a working razor?

I liked that semi-rounded point (Spanish? I don't know.) that was drawn in red.

J.

-

03-03-2009, 02:03 AM #29

Wouldn't mind something with a smile on it. 1/4 hollow sounds good. Maybe a nice barber notch to liven it up:

-

03-03-2009, 02:14 AM #30Senior Member

- Join Date

- Jan 2008

- Posts

- 701

Thanked: 182

that's what im talking about

pick you point heel and grind

so far as finish i have to see what kind of belt progression i can get to work out

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote