Results 1 to 10 of 161

Thread: custom ish blade blank project

-

02-25-2009, 04:39 AM #1Senior Member

- Join Date

- Jan 2008

- Posts

- 701

Thanked: 182 custom ish blade blank project

custom ish blade blank project

so what would you all like to see

i think i can get a line on a sheet of 52100 high carbon blade steel

and im working with don and lynn on offering blade blanks from SRD

but need feed back cause of the $$ on set up

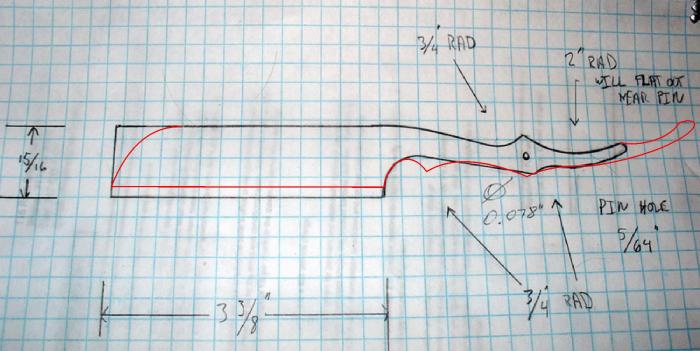

so you could take the pic(at bottom ) and draw what you wanted you blade to look like (inside the lines ) and then ask for a grind style

the blade would be fully heat treated and belt finished ready for scales and honing

you option of std pin hole or 1/8 folder pivot set up with all hard ware (screws washers and pivot its self)

feeed back welcome

-

The Following User Says Thank You to L R Harner For This Useful Post:

Big Red (02-25-2009)

-

02-25-2009, 04:44 AM #2

Yes! this needs to happen... just the type of thing I've been looking for!! What kind of $$$ are we talking about for a blade completely done, out the door?

-

02-25-2009, 06:55 AM #3Senior Member

- Join Date

- Dec 2008

- Location

- San Diego/LA, Calif.

- Posts

- 268

Thanked: 27

I'm interested in that blade blank, but how about in STAINLESS steel?

-

02-25-2009, 07:07 AM #4

Very interested if the price were possible! I mean come on, I know that personally I have bought blades for 115 bucks knowing I'd need to do work on them and put new scales.

My question is would it be possible to get them pre-heat treat to do any file work like jimps, spine fanciness and what not, or change the point style? would it all be one thickness?

I'm excited man, keep us posted.

Red

-

02-25-2009, 01:42 PM #5

-

02-25-2009, 02:00 PM #6

I think the great thing about this is gusy that have vintage blades that are more rare, like the 10/8's, the case with the big smile etc. we can ask them to trace the blade out on graph paper for us and send it off.

Red

-

02-25-2009, 02:08 PM #7

-

02-25-2009, 02:18 PM #8Senior Member

- Join Date

- Feb 2007

- Posts

- 392

Thanked: 105

Do we have to stay inside the lines. Or could this be an option.

-

The Following User Says Thank You to oldblades For This Useful Post:

heck (12-09-2009)

-

02-25-2009, 02:23 PM #9

This would be a great material for a contest for the best looking or best shaving razor.

-

02-25-2009, 02:57 PM #10Senior Member

- Join Date

- Jan 2008

- Posts

- 701

Thanked: 182

for this project it would need to stay between the lined

so far as SS might do one or 2 if need be later

and as far as

non hard spine for work

you i think would have to pay both ways shipping to do the work then have me finish the hardening

so far as one offs or old school blade shapes

maybe depending on work load

remember all i have to make sure i have time to keep making kitchen knives and other sharp stuff

-

The Following User Says Thank You to L R Harner For This Useful Post:

oldblades (02-25-2009)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote