Results 31 to 40 of 41

Thread: collarless pinning of Ivory

-

06-29-2011, 01:51 PM #31Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

One thing I do know from a metal working standpoint at least,is a chamferd hole distributes stress alot better than one that is not.

As I have said above,Ivory is alot stronger than people realize,Is just unpredictable.

-

06-29-2011, 03:29 PM #32Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

Nice work - looks perfect. You did it the old original way too - without doming the end of the pin. Most silversmiths do it that way too, and the videos I have seen from the 70s - 80s show people working in Sheffield razor factories doing it the way you did. It's a bit too risky for me - I dome one end - but I suppose if you were doing it all day every day you get to know whats what!

I always use a tapered ream to make the hole conical - it helps to accommodate the percussion bulge at the top of the pin, and I always make the hole a bit wider than the pin. Ivory shrinks and swells with the ambient temp and atmosphere, and if it shrinks on an already too tight pin it can crack - I see this on loads of old razors. Interestingly, it seems to happen on one side more than the other - usually the back scale in most of the ones I see. I must have about 30 or so rear scales, all cracked at the pin, and only half a dozen top scales.

Regards,

Neil

-

The Following User Says Thank You to Neil Miller For This Useful Post:

sharptonn (06-29-2011)

-

06-29-2011, 08:02 PM #33

Many Thanks, Neil. The tapered reaming of the hole makes sense! We know how difficult it is to remove this type of pin from ivory, and I think this bulge you speak of is the culprit! I wonder why the back scale is often cracked? Perhaps the natural pressure on it during the return stroke while stropping? This is very good advise from all!

Tom

"Don't be stubborn. You are missing out."

Tom

"Don't be stubborn. You are missing out."

I rest my case.

-

06-29-2011, 11:48 PM #34

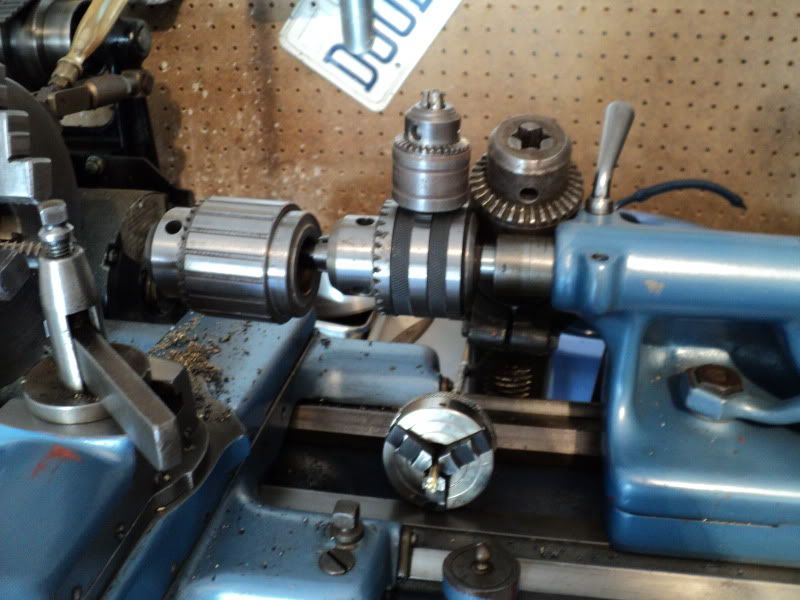

I thought I would share my pinning anvil I dreamed up as a result of this thread and everyone's fine advise!

I was tired of going out to the hot shop and using the anvil on my vise to pin, and I liked the idea of using a drill chuck to dome pins, so I welded up an old Jeep spring shackle for a base and a discarded fork tube from my old CZ dirtbike, along with a hunk of 3/4 steel, drilled out and tapped in the middle to accept a drill chuck/rocker stud! I can now sit in my chair, rest my feet on the base and dome pins, remove the chuck and pin on it. I will probably make some doming divots in it as well. Domed my first pin on it and it worked well. I am already thinking of a bolt to thread in there, drilled out in the middle, for tapping pins out. I wonder how many old pins the fork tube will hold? It will be nice to have, I think!

I was tired of going out to the hot shop and using the anvil on my vise to pin, and I liked the idea of using a drill chuck to dome pins, so I welded up an old Jeep spring shackle for a base and a discarded fork tube from my old CZ dirtbike, along with a hunk of 3/4 steel, drilled out and tapped in the middle to accept a drill chuck/rocker stud! I can now sit in my chair, rest my feet on the base and dome pins, remove the chuck and pin on it. I will probably make some doming divots in it as well. Domed my first pin on it and it worked well. I am already thinking of a bolt to thread in there, drilled out in the middle, for tapping pins out. I wonder how many old pins the fork tube will hold? It will be nice to have, I think!

Last edited by sharptonn; 06-29-2011 at 11:55 PM.

"Don't be stubborn. You are missing out."

I rest my case.

-

06-30-2011, 10:09 PM #35

I didn't mean the drill chuck should be held in a vice, although it could. Or bolted to a vice, for I believe many of them have standard Unified threads. But I think still attached to the drill, and rested on your thigh, would give all the inertia you need for this job.

-

06-30-2011, 11:31 PM #36Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

On the other hand if you have a spare layin around is always nice to have a dedicated tool

-

The Following User Says Thank You to pixelfixed For This Useful Post:

sharptonn (07-01-2011)

-

06-30-2011, 11:56 PM #37

-

07-01-2011, 10:40 AM #38Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

-

07-09-2011, 03:17 AM #39

Practical Observations

Practical Observations

I have done the wedge end of 2 razors. Pain in the ass! Had to redo the big one again. But I am learning about annealing and it is truly interesting. Seems if you heat it too much, the pin leans over fast! Satisfied with these. I hope the experience helps on the pivot end!

Last edited by sharptonn; 07-09-2011 at 03:20 AM.

"Don't be stubborn. You are missing out."

I rest my case.

-

07-09-2011, 03:24 AM #40

Nice work and some great advice being contributed. Is the heat necessary ? Would you recommend heating the pin ends for pinning acrylic or celluloid as well ?

Be careful how you treat people on your way up, you may meet them again on your way back down.

36Likes

36Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote