Results 31 to 40 of 45

Thread: Mirror finish

-

04-05-2012, 04:49 PM #31

It's ok everyone is entitled to there own opinion. This is after 400 grit

-

04-05-2012, 04:57 PM #32

-

04-05-2012, 06:57 PM #33

Nice Boker that should turn out nicely. Looks to be in really nice shape. Don't think it should take much to make it shine.

-

04-05-2012, 07:02 PM #34

I just need to concertrate on the sandid. And when I use Marco mesh how do I use it I have all sorts of Grits but I'm not sure how to use them

-

04-05-2012, 07:19 PM #35

From the pictures I would go up to like 1500 or 2000 grit and then spend 20-30min polishing it and see how it turns out. Might not really have to go as high as the micro mesh, but I guess it all depends on what you are going for. As for mirror finish I have one that I can read the date off of a dollar bill, but still shows pitting. If you are wanting it to be free from all imperfections you might be aiming to high, but that is just my thoughts. I have OCD when it comes to stuff like this and sometimes I have to force myself to put something down and say that is enough cause no matter how far I go I can always find something wrong with it. Micro mesh I use like any other sand paper. I've used the cushioned pad types makes it easier to mold to the form of the razor. Also when I use sandpaper I cut them into widths as the razor and about 2 inch strips makes it easier to control, but others might find that excessive cause your fingers will tend to hurt after awhile doing that.

Last edited by JSmith1983; 04-05-2012 at 07:27 PM.

-

04-05-2012, 07:21 PM #36RazorBase DB application developer

- Join Date

- Jan 2012

- Location

- West Midlands, UK

- Posts

- 299

Thanked: 67

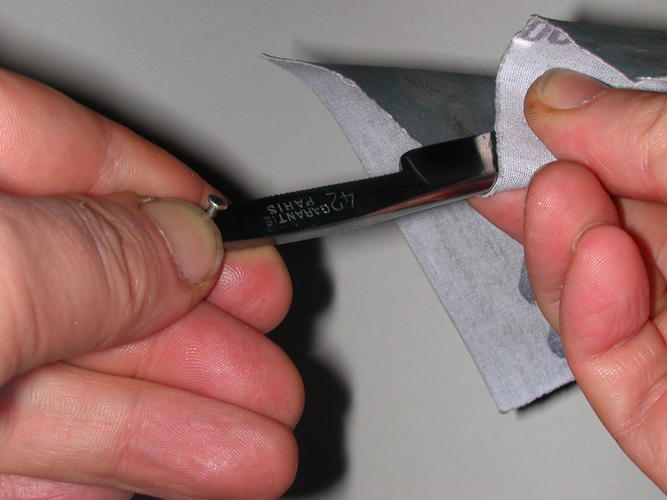

I've found that wrapping the micro mesh round the blade (from the spine side, obviously!) and rubbing up and down works pretty well. Since you've got the blade free of the scales, you might find that putting a small nail through the pivot hole makes the blade much easier to grip:

For sanding the flat parts (the sides of the tang), you can put the micromesh face up on a piece of scrap wood and sand the blade back and forth over it.

Seems to take forever, though - put a DVD on!

-

04-05-2012, 07:41 PM #37

I would like to to be able to see a perfect reflection

-

04-05-2012, 08:08 PM #38

That's OK, I think a fine satin finish on a highly tuned Str8 blade is a thing of beauty of in itself!!

Buy if mirror is what you want, you will, as others have said, need to puchase your self a Buffing set up with a good motor, ideal? 1750Rpm's and about 1/2 Hp Thoug I have use 1/3Hp one that seems to put out a honest amount of work.

JMHO have fun what ever you decide, that's what its all about this great hobby of our!

Most Sincerley, tinkersd

-

04-05-2012, 08:15 PM #39

-

04-05-2012, 08:24 PM #40

My young apprentice; Like and Need are two entirely different concepts!

Did you find the razors that you sent me and I had put into new scales, then polished and honed and sent to you unsatisfactory? As my memory recalls you were delighted with the results including the finish on the blades!

Perfection can be a very misleading and dangerous goal! While I have on occasion misused the term ‘Mirror Finish’, Glen is Correct in that a ‘Near Mirror’ finish is achievable but not always desirable!!

Patience and Tolerance are always desirable!!

21Likes

21Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote