Results 91 to 100 of 106

Thread: Wooden Scale Advice

-

08-17-2012, 09:21 AM #91Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

-

08-17-2012, 12:24 PM #92At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,064

- Blog Entries

- 1

Thanked: 13249

-

08-17-2012, 12:41 PM #93Señor Member (the name is Dave)

- Join Date

- Feb 2012

- Location

- Sarver, Pennsylvania, United States

- Posts

- 683

Thanked: 88

My opinion on the matter relates to cars. There are plenty of vintage restores out there. There are also plenty of hotrods. I have a nice old extra hollow Clarke in three-pin horn scales that I would consider a classic. I just chose a (conservative) hotrod route for my W&B restore. There's room for both, even in the same collection.

-

08-17-2012, 11:39 PM #94Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

-

08-18-2012, 01:27 AM #95Senior Member

- Join Date

- Apr 2012

- Location

- Jersey City

- Posts

- 225

Thanked: 50

True enough for a good long time. However.

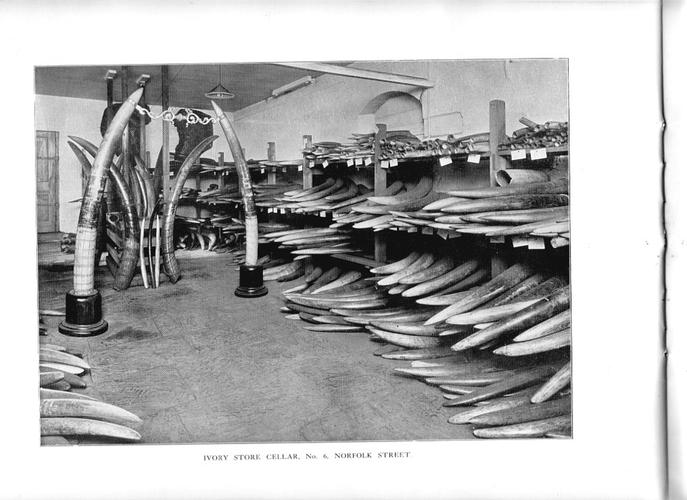

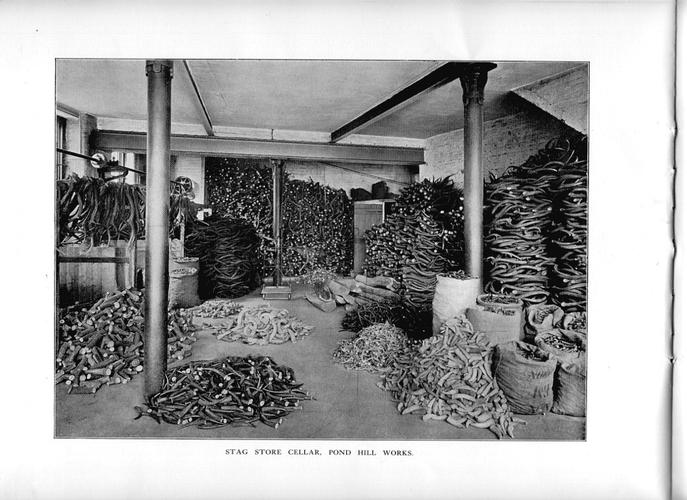

Forgetting for a moment how they sourced their materials, these materials were used on their higher end and more profitable cutlery lines, knives and razors for which Joseph Rodgers were famous. Thus a larger degree of waste in the manufacturing process could be tolerated.

It was somewhat arrogantly presumed that both the source for the materials, the demand for hand craftsmanship and the market for their finished products would continue indefinitely. That wasn't the case. The US assembly line method of manufacturing, with it's lowered cost of production and higher profit margins which would help to start the decline of the Sheffield and Solingen industrial centers.

History repeats itself. There are distinct parallels to the current growth of industrial capacity in China and India with the decline in the US and European counterparts and the development and the growth of the US industries a century ago and the decline in the old European industrial centers. The European merchants of the 17th and 18th century were successful, in a large part, because of the exploitation of cheap resources and to the demand for their products in the US. The US became an economic powerhouse when they stopped importing goods (helped in large part by tariffs) and began manufacturing goods for their own consumption. This pattern is repeating itself in Asia.

The History of Joseph Rodgers - Egginton

To parkerskouson, sorry about the digression on your thread about the walnut scales. I would like to see your progress with them.

-

08-18-2012, 02:00 AM #96Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

08-18-2012, 02:22 AM #97Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

-

08-18-2012, 02:59 AM #98

Of course we are talking about back in the day, when razors were scaled in ivory. Things certainly declined in these centers from the old days! In a physical way! We are light-years away from the way things were done back then. I am glad to see some old industrial centers coming back in a modern way! I wish it would happen in my country.

-

08-18-2012, 04:02 AM #99Senior Member

- Join Date

- Apr 2012

- Location

- Jersey City

- Posts

- 225

Thanked: 50

"Sheffield, I suppose, could justly claim to be called the ugliest town in the Old World"

George Orwell, 1937

-

08-18-2012, 06:29 AM #100

O my if only we Brits could buy and work Ivory, it's a material i would love more than anything to work with, i would re-scale a vintage razor, then send a piece off to Bill of Le Tuft brushes and have a brush made to match the scales.

Jamie.“Wherever you’re going never take an idiot with you, you can always find one when you get there.”

74Likes

74Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote