Results 11 to 20 of 20

Threaded View

-

04-27-2013, 08:20 PM #1

Restoring a B.J. Eyre & Co Challenge, looking for some advice

Restoring a B.J. Eyre & Co Challenge, looking for some advice

Update/Edit -

So here is an update. I went to Home Depot and bought a filing kit and was able to file the pins down. I disassembled the razor and the first thing I noticed was how sticky the spacer was. It looked like it had sludge on it. The sludge was also around the pin hole of the razor.

I put some Mothers near the tail and pin hole and started buffing away. I knew I would need to get some Mothers in the pin hole as well to get out any rusted metal. I found a leaf on the ground and started using the bottom of the stem to get the Mothers in the pin hole. Within a minute or so, I was literally scooping metal out of the hole with the leaf. The metal was so corroded it turned into the sludge I mentioned earlier. The crater that is in the handle is a little more than 1/8 of an inch, though the actual hole itself is a little smaller. Before I continue putting anymore work into it, I was curious if this would be a huge problem. I don't have many tools at my disposal. I haven't made scales before, nor have I tried repinning a razor. I imagine if I were to finish the restoration (which I would like to do), I would need to make the hole uniform so I could have a pin fit snuggly in there. Would I need to get a round file and slowly make the inner hole match the size of the crater?

Anyway, after an hour of Mothers and elbow grease/butter alternative, most of the active rust has come off. There is still some near the top end of the blade, so I think I'll need to grab the sandpaper. It isn't nearly as bad as I was expecting it to be, so I'll start on the higher end and work my way down if need be. Thank you everyone who has contributed thus far, your help is very appreciated.

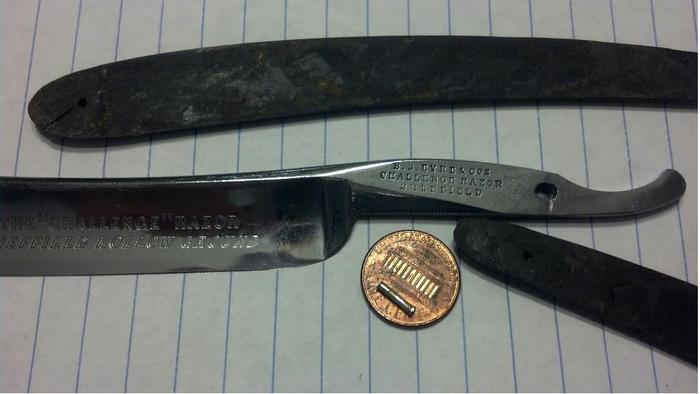

I was shopping around at the local flea market and came across this razor out of Sheffield. The man had it marked at $35, but after talking to him for a while about restoring it I was able to snag it for $20. There is a good amount of active rust on the spine. It isn't covering the entire top of the blade face and spine, but there is enough there to do some damage. The face and cutting edge of the blade are in pretty decent condition. The scales are original and there is a small crack by one of the pins. It measures out to a hair below 6/8. Out of the handful of straights I have, this is bar far the heaviest.

I don't have a drill press or a dremel, so I can't get the pins off just yet. I figured in the mean time I would get my 80 grit wet/dry sand paper and start getting the active rust off where I can. The stamp on the blade face isn't incredible deep, and I would like to preserve as much of it as possible. Would it be wise to run a course of Mothers and then start sanding, or should I just go for broke and go straight the the sanding process?

Though it has more rust than I would like (obviously), I felt that rust wasn't bad enough to warrant passing up on the razor. Any thoughts, comments, or suggestions are certainly welcome.

Last edited by Jonah; 04-28-2013 at 07:50 PM. Reason: This just in.

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote