Results 121 to 130 of 143

-

02-03-2016, 08:49 PM #121

-

02-03-2016, 09:50 PM #122Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,393

Thanked: 3228

-

04-02-2016, 05:15 PM #123Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,467

- Blog Entries

- 1

Thanked: 4207

Trying to honor the sanctity of thread continuity I'm returning to this one to chart the final work on this #3.

Going to pop out the boar and install a shavemac 24mm. So proceeded to try a double boiler and steam for 45 minutes or so to no avail.

So tried acetone, and still no dissolving of what I thought to be epoxy, then I worked the base with my dremel a bit along the edges to test depth of sealant and the smell of the ground material told me what I was working with.

The rubberset brush knot is set with rubber....

So, revisit my approach and soak base inverted in kerosene, petroleum products eat petroleum products, then apply some localized intense heat from below and voila.

And initial test fit, pre bonding of the new beautiful badger.

Really does suit, IMO.

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following 5 Users Say Thank You to MikeB52 For This Useful Post:

engine46 (08-01-2016), Geezer (08-01-2016), HARRYWALLY (08-11-2016), Phrank (04-02-2016), sharptonn (04-02-2016)

-

04-02-2016, 05:25 PM #124Senior Member

- Join Date

- Oct 2010

- Posts

- 26,211

Thanked: 8626

Thatsa' nice, Mike!

Nothing more to say........

Nothing more to say........

-

04-02-2016, 06:04 PM #125

Oh my....that's lovely.....

-

08-01-2016, 01:35 AM #126

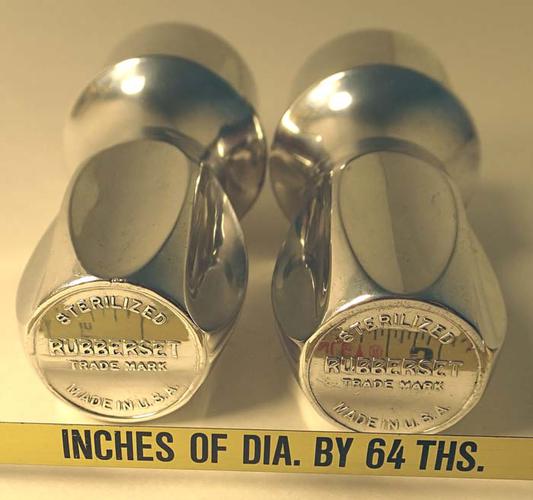

Frank, I learn something everyday like why the hell I never saw this thread? If anyone ever needed the measurements for the original aluminum Rubberset brush handle, I could have sent ya here:

OSSB - Rubberset 400

Anyway, I enjoyed reading it all & even the indexing on a lathe. I know my old lathe doesn't have anyway of doing that but I thought about marking the piece that needed to be cut out for the flutes. Benz can do it really easy on a Bridgeport. I did see a wooden brush B52 made not too long ago.

-

The Following User Says Thank You to engine46 For This Useful Post:

Phrank (08-01-2016)

-

08-01-2016, 03:35 AM #127

I'll tell you Engine - that Shavemac D01 knot, superb, the two brushes that never move from my bathroom shave den are this Rubberset and my Morris & Forndran L7...the Shavemac is the closest brush I've used to the M&F...the rest just feel like varying degrees of soft to silky smooth on the face - for me, gotta have that large scritch factor...

Sheesh...a large Helicopter just flew over my house...real low like....gulp!!

-

08-01-2016, 03:47 AM #128

Ha ha Andrew, you were mentioning that large scritch factor & a large Helicopter flies over........

I guess it is okay as long as it didn't crash. I remember a few years ago hearing a plane flying low about the time I was waking up one morning & they said there was a plane crash a short while later. It was a small jet going to pick up George Bush Sr. at the airport here in Houston. He's lucky he wasn't on it yet. The jet crashed about 1/2 mile from where I was living. Apparently the pilot was flying too low when getting ready to land.

I want to get a Shavemac brush.

-

08-01-2016, 08:36 AM #129

I froze water in the handle and then dipped ferrel in almost boiling water. Broke loose in a couple minutes.

Shiny is best. My 3 & 4.

Love the fluted handle's feel.

Sizing HMW knots and still in shining process.

Almost there with Mother's Mag & Aluminium Polish and old T-shirt & Q-Tips.

Done.

...Shave the Lather...

-

-

08-01-2016, 02:08 PM #130

Question I'm sure has been asked a million times, what is the difference between the #3 and the #4?

489Likes

489Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote