Results 11 to 20 of 32

-

03-30-2012, 12:28 PM #11

As long as you have a good "flare" the size of the cut isn't a factor in relation to the tang. Where it DOES matter is the wedge side, the cut should be the same size as the part of the head you want it to contact. Definitely no larger than the spine.

I hope that makes sense.

-

03-30-2012, 12:39 PM #12

It does, thank you. Since I will be using my old scales as a template I can check how wide it is on that one and try to make it the same. I will also take the width and length of those scales as well.

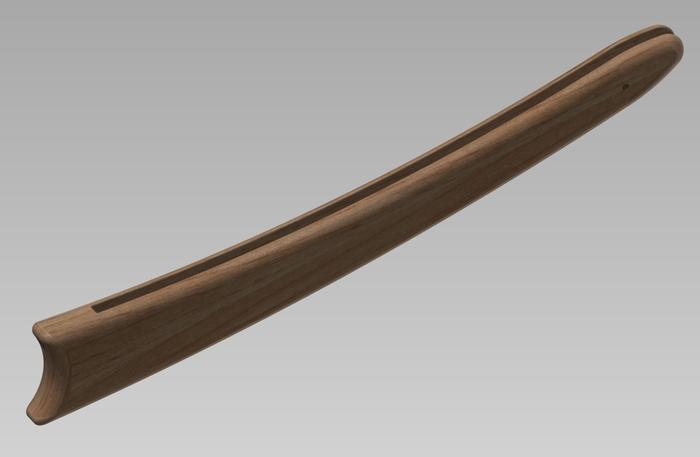

I redid the model again after Glens advice on how to create the "flare" and hopefully when I'm done it will look something like the pictures below.

Just hoping I will find the time to do it now.

-

03-30-2012, 03:24 PM #13Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

I have really enjoyed this thread, and your thought process as you worked through your project up to this point. Read what Glen (gsixgun) has written carefully - he is one of the very best at restoration. One piece scales are very tricky to get right. Good luck, and I look forward to seeing your results. For what it's worth, I would rather work with wood that is the color I want to begin with, rather than using stain. Cocobolo, African Blackwood, etc.. JMO. Again, good luck.

-

03-30-2012, 07:36 PM #14

Yes, I would like to use Ebenholtz, Pockenholtz or something similar but the problem is I live in a small flat and got no tools what so ever except a Dremel and hand tools. The cabin is about 200 miles away so I really don't go there that often and since I'm gonna be there a week and all necessary tools are there (including wood) I thought I would give it a go and see how it turns out since there really isn't a lot to do in the middle of nowhere.

Besides I got the chance to practice without actually have to spend a dime.

Besides I got the chance to practice without actually have to spend a dime.

I promise I will keep you all updated and post some pictures of the final result unless it turns out really crappy.

-

03-30-2012, 07:47 PM #15

Well seeing that you guys are talking all this tech stuff I might as well tell you that I don't know squat about making scales. But, what I can tell you is what I like, and I like. You do amazing work PMH! Those look outstanding!

-

03-30-2012, 07:53 PM #16

Mike you DO know that those are just renditions right?

-

03-30-2012, 08:49 PM #17

I have noticed some older scales where one is slightly longer than the other so when pinned it caused bowing to accept the blade. Could this work with one piece scales?

-

03-31-2012, 12:15 AM #18

I think you did an amazing job, I disagree they need more curve " cuase it looks better " it all subjective, I personally like starighter scales similar to what the guys over at Heart are doing. these look great, with people like Glen helping you out and your own R&D, you'll have these perfected in no time. Keep us posted!

-

03-31-2012, 01:22 AM #19

-

03-31-2012, 02:39 AM #20

Take an old razor and measure from pin to pin on each side and sometimes one side is a hair longer than the other. If the scales are taken apart and the pin holes on the tang side of the razor pined with a microfastner you will see one scale a little longer than the other. Its not that the scales are actually longer but the pin holes at the tang end are not drilled at exactly the same distance from the wedge end. I will look around for a set of scales to show as I'm not sure I've explained it exactly right.

15Likes

15Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote