Results 21 to 27 of 27

-

06-11-2015, 05:04 PM #21Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209 Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

06-11-2015, 05:12 PM #22

My O2 is dark blue at the end.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

06-11-2015, 05:19 PM #23Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

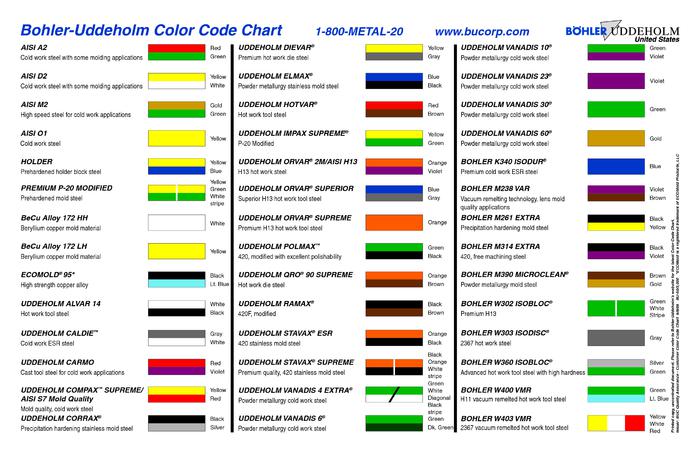

Uddeholm steel color chart

Wordpress Color Codes | Coloring AnythingRandolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

-

06-11-2015, 05:25 PM #24Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Victor, I just did some quick searching and I think your correct. Ok, so now I will try the spark testing and density methods.

But no matter what the outcome I will still be using these steels as is ! Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

06-11-2015, 08:43 PM #25

-

06-12-2015, 01:42 AM #26Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

All else aside, at worst, you have a lot of material for making good tools and such. Might have some folding knife blades hiding in the block of D2 if you are so inclined.

My experience with US suppliers like Alro is that yellow on the end means 1018. The HRA(hot roll annealed) is probably 1018 too.

My experience with US suppliers like Alro is that yellow on the end means 1018. The HRA(hot roll annealed) is probably 1018 too.

-

The Following User Says Thank You to JDM61 For This Useful Post:

Slawman (06-29-2015)

-

07-01-2015, 05:05 AM #27Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

So far I have been working on putting together the parts for the post anvils. I now have 4 of the disc brake rotors for a base plus I have found the tubing to fit the various anvils and a guy who will do the cutting and welding ( Randy Stinar in Cannon Falls). They should be done in about 3 weeks.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

37Likes

37Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote