Results 21 to 30 of 151

Thread: Air hammer?

-

08-20-2015, 08:01 PM #21"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

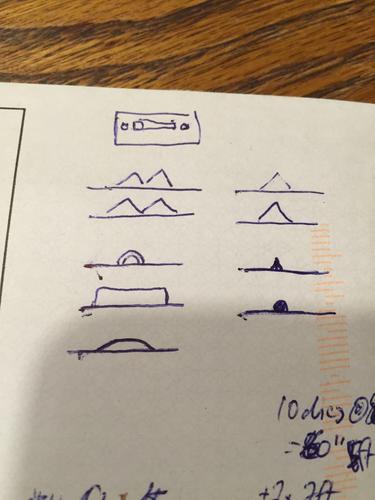

Think of a press as a big slow hammer. The main difference, depending on die shape and available pressure, is that a hammer will tend to work the billet from the outside toward the center and the press will tend to work the billet from the center outward. This is the only advantage I can see if you're making patterned steel as it tends to close up any inclusions in the middle of the billet and squeeze the crap to the outside. This reduces (theoretically) the scrap rate in billet production.

I know smiths who use one or the other with good effect and swear by their tooling. I know smiths who have both. It's what tool you have and how you get to know how to operate it. I use hydraulics for welding, but I can weld in a power hammer too.

Forget anything hand operated, or with any lag in getting the top die into the steel in a quick hurry. Welding won't wait more than seconds. That being said, as good practice for the newbies, enough grunt in the press will make up for some temperature loss and you could weld at temperatures that critics would say were impossible. Give yourself a few years and you'll probably figure out what I mean.

Fast rpm electric motor turning a 16-22gpm hydraulic pump into a six inch cylinder on an H-style frame. These have been made in a C-style too (historically the first ones were former log splitters), but the H-style is more stable and less likely to bend over time. OTOH log splitter frames are cheap.

The idea that you don't need much force to weld a billet is very true. When I first "set" the weld in my press I barely squeeze at all. Then I rock and roll to forge out the billet and create as much movement in the random patterns as I need. The hydraulic press can be very controllable, but that's true of any forging tool. Dies make the work more efficient.

If I could have only one tool, it would be a power hammer. There's a lot more that could be said but this is the gist.

-

The Following User Says Thank You to Mike Blue For This Useful Post:

Cangooner (08-20-2015)

-

08-20-2015, 08:41 PM #22

Thx. I was probing more for whether the 6t air version would be effective for drawing out billets but I totally appreciate the advice.

-

08-20-2015, 09:47 PM #23

The press we use has a forklift ram as the driver. Takes a lot less time than the press in the video. If you are skilled with the lever and coordinated, you can get around 2 presses per second. We use fullering dies for drawing and flattening dies to straighten and flatten some of the ridges on the billet.

-

08-20-2015, 11:09 PM #24"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

-

08-23-2015, 08:50 AM #25

It's just physics. You can use a lighter press if you use smaller dies.

-

08-24-2015, 03:47 AM #26

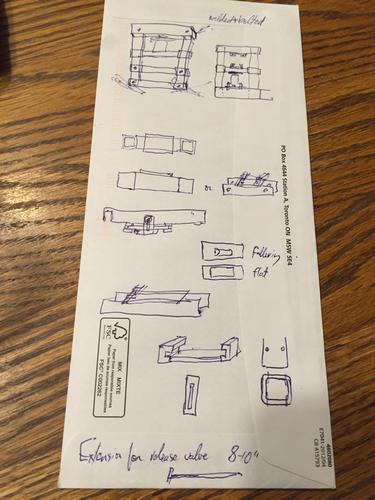

Well, I am in it now. I picked up the 20t jack and some steel and am working out the approach for a press. Hopefully a hammer won't be far behind. I have most of the stuff now anyhow.

-

08-24-2015, 11:53 PM #27

Excellent! Please take plenty of pics as I'd love to see it come together.

Good luck

It was in original condition, faded red, well-worn, but nice.

This was and still is my favorite combination; beautiful, original, and worn.

-Neil Young

-

08-25-2015, 03:03 AM #28

Just fyi, I am not fast... Two kids, busy job etc. However, I love this stuff and may be able to get some help in exchange for beer. I don't have room for a band saw but I can get my hands on one for cheap as a loaner.

-

08-28-2015, 04:50 PM #29

Guys, would a threaded Clovis pin end work for the end of a pneumatic tie rod actuator (for the hammer)? I think I am going to pick up something to try this weekend. Still need lots of steel though, and time!

-

08-28-2015, 05:00 PM #30

Something like this:

80 mm Bore x 200 mm Stroke Pneumatic Tie Rod Cylinder | Princess Auto

and this:

Clevis with Pin | Princess Auto but in the proper size

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote