Results 41 to 50 of 151

Thread: Air hammer?

-

09-10-2015, 03:42 AM #41Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

My experince with the smaller press has been that the it is great when things are big, but once you get down below 1/2-3/4 of an inch, you are thinning out the billet as much by putting scale on the floor as by actually moving the metal

My dream shop would have a "four poster" press in the 40 ton plus range like the one that Matt Whitmus builds, something like a 100 pound plus power hammer like a Say Mak, Iron Kiss or one of the German hammers and a Whitmus rolling mill with the twist feature on the end of the rollers. With that, I could conquer the world, but we are talking about $25-30,000 worth of gear minimum.

My dream shop would have a "four poster" press in the 40 ton plus range like the one that Matt Whitmus builds, something like a 100 pound plus power hammer like a Say Mak, Iron Kiss or one of the German hammers and a Whitmus rolling mill with the twist feature on the end of the rollers. With that, I could conquer the world, but we are talking about $25-30,000 worth of gear minimum.

-

09-26-2015, 03:50 PM #42

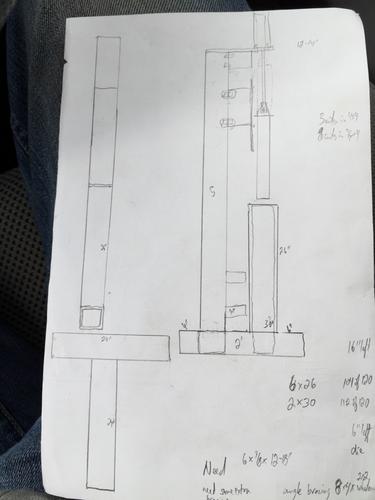

Think I'm back to the hammer. Got steel, pneumatic actuator, and hoping to rent a band saw today.

Hope this turns out... By the plans I have now I will be welding most of the connections, especially at the base, but I will try to add overlapping steel straps welded in place.

The anvil should be about 5.5x6" by 26" high, sitting on top of the 4x4 base, so the working height will be about 32" high, or higher if I make a wooden platform of 2x4 or 2x6 boards.

-

09-26-2015, 03:53 PM #43

If I stick with the steel round for the hammer and the base as described, I will only be about 5:1 for anvil:hammer weight. We'll see.

-

09-26-2015, 05:06 PM #44"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

When your build gets to the working stage, have a friend video the hammer operating from different angles. Watch the video looking for the hammer moving around. It will give you clues as to where it might need some more bracing to prevent flexing/bending and the hammer coming apart on you later.

If you're in there hammering steel, you get lost in the work, paying attention to the hot work piece and can't see things happening right in front of your head.

-

The Following User Says Thank You to Mike Blue For This Useful Post:

Atchbo (09-26-2015)

-

09-26-2015, 05:13 PM #45

Cutting...

-

09-26-2015, 10:04 PM #46

Attachment 213469

More...

-

09-26-2015, 10:05 PM #47

Some more...

-

09-26-2015, 10:08 PM #48

Man, cutting through this thick steel takes a long time!

I am making a jig for bolt holes and will likely come back to this work in a few weeks. Maybe I'll be able to sneak in some welding here and there.

-

09-27-2015, 06:21 PM #49

Cutting is done. I shortened the hammer head to 15" which is still plenty. Probably 35-40 lbs.

Does anyone have strong opinions about whether 4140 (or any hardened spring steel) is needed for the dies?

-

09-28-2015, 03:35 AM #50aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

No input here, just enjoying the journey with you~!

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote