Results 71 to 80 of 151

Thread: Air hammer?

-

10-02-2015, 02:25 PM #71

I wonder about condensing inside but I was thinking sand or small gravel too.

-

10-02-2015, 07:21 PM #72

Got the last of my steel today... this is going faster than I thought! And my wife hasn't killed me yet!

-

10-02-2015, 10:33 PM #73"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

I like your heavy plate anvil/sow block. I'd recommend some sort of strapping or a cover weld with a plate, something to keep all those standing plates from coming apart when struck on the end.

-

10-02-2015, 11:56 PM #74

Yep. I may bring it over to a friend's place with a stronger welder. Heavy fillet welds on the long seams, and a plate on top, with the another 6" of round stock will make up the anvil.

-

10-03-2015, 10:34 PM #75

Gnarly.

One good looking weld!

-

10-05-2015, 02:39 AM #76

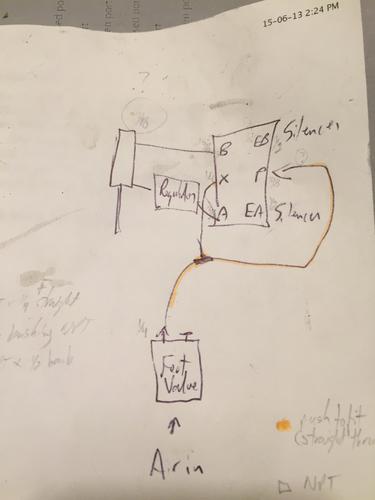

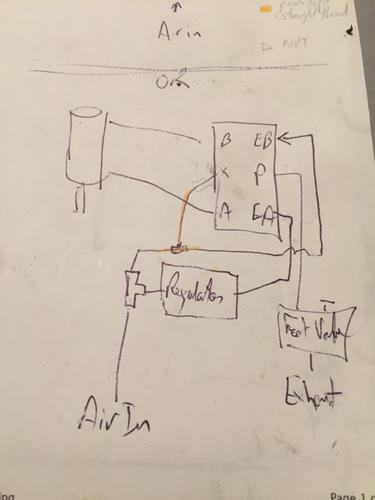

Two pneumatic designs: one routes the incoming air through the foot valve and then into the common port of the valve, which means I need a regulator on the hose going to the 'up' hose (edit: I doubt this would work, as the down stroke would need to go through the same hose unimpeded, which would require a bypass). The other is to split the air, send one through a regulator, and then have the foot valve take the exhaust function (but the one I have has only 1/4" ports). Maybe the second option requires the ball valve for the exhaust.

-

10-05-2015, 02:41 AM #77

I suppose in 1) I could put a regulator on the exhaust port before the silencer, but the air will have decompressed, so unless it's just a half-closed ball valve, I doubt this would work either.

-

10-11-2015, 09:23 PM #78

-

10-11-2015, 09:24 PM #79

-

10-18-2015, 10:48 PM #80

Mocked up!

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote