Results 1 to 10 of 69

Thread: Vermio; The Black, Greek hone

-

02-09-2016, 05:15 PM #1

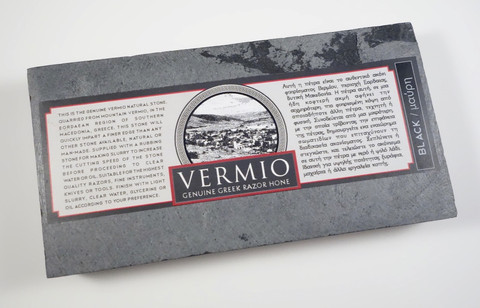

Vermio; The Black, Greek hone

Vermio; The Black, Greek hone

I just received this bad boy yesterday. It's my first natural stone. I have a 5, 8 and 12k Naniwa SS. I picked it up for specific reasons. A) didn't see much about them on here B) I want to play with slurry, felt left out

C) It was relatively cheap, not a 800 natural japanese stone that was used by someone whose skills would make me look like an infant smashing two stones together. I'm also inexperienced at honing, trust me this is all necessary information, hehe. I got the 3" x 5-3/4" size, comes with a free slurry stone (score!) of the same material. Pre-lapped by the seller (dunno if it's rude to mention them? google's your friend and so are PM's, to be on the safe-side) though I was quite skeptical, I have burned by "professionals" in just about every industry and occupation. When I unboxed the stones, the top of the hone looked reasonably flat and it was pretty apparent it was lapped. The bottom and sides are pretty rough, you can see the saw marks and the bottom looks like it was cleaved off fairly roughly. I figured, at least the corners are rounded and it feels hard, but lighter in weight than I anticipated. Might as well try what they have done so far, running low on sandpaper as it is anyways.

C) It was relatively cheap, not a 800 natural japanese stone that was used by someone whose skills would make me look like an infant smashing two stones together. I'm also inexperienced at honing, trust me this is all necessary information, hehe. I got the 3" x 5-3/4" size, comes with a free slurry stone (score!) of the same material. Pre-lapped by the seller (dunno if it's rude to mention them? google's your friend and so are PM's, to be on the safe-side) though I was quite skeptical, I have burned by "professionals" in just about every industry and occupation. When I unboxed the stones, the top of the hone looked reasonably flat and it was pretty apparent it was lapped. The bottom and sides are pretty rough, you can see the saw marks and the bottom looks like it was cleaved off fairly roughly. I figured, at least the corners are rounded and it feels hard, but lighter in weight than I anticipated. Might as well try what they have done so far, running low on sandpaper as it is anyways.

The test, I had a little bit of a rough shave on my Case razor, I didn't hone it very well. Probably only my 6th time honing a razor, growing pains to be expected.

*Throughout the process I checked with TPT after 5-10 strokes and practiced with 5x loupe for giggles, started to be able to see clearer once I already moved to vermio*

1) Rub blade on side of hone, dull it out.

2) Broke out my 5k, used a little 1000 grit to build up a little slurry. Used swooping X's as outlined in gssixgun's tape vs no tape video, have had toe sharpness problems.

-Helpful for me, slurry helps to see the edge contact with hone. Overhead lighting always puts my head shadow over hone.

3) Went straight to the vermio, supposed to be 12-14k. Built up a slurry to skim milk-ish thickness, it is a light gray/white. watering it down in increments to try to polish bevel, reasonably successful

-Insert a consecutive stream of swearing, can see this working soooooooooo well and feels reaaaaaally nice.

-Suddenly wondering if I screwed up, I used the saw pattern edge of slurry stone, maybe should have used smoothest side?

-Had one stroke where it felt like I was using 220 grit sandpaper, got into a groove and accidentally tried to hone my stabilizer.

4) Test shave, so -bleep- great!

In conclusion, I love this stone. It just "feels" right. As an engineer, it annoys me to no end that I cannot quantifiably describe how nice this hone is for me. I think it's a really good beginner hone. I have problems keeping a good stroke on the longer Naniwa's, because I'm too stubborn to just use half of it and I want to be able to do it. I am thinking of lapping this stone with even finer grit, maybe confirm what seller used, so I don't back track. Lapped surface is blacker than rougher surface, kinda interested how polished I could get it. Would theoretically make it smoother hone or am I just going to spin wheels and make a rock look purtty?

I used the side facing camera to create slurry. The sides facing up, down (contact w/ stone) and left seemed smoother. Better, maybe? Looking at you j-nat experts

Some slurry, looks grittier than it felt. I may have slurried more?

This is just a jpg from seller's sight, forgot to take more pictures of non-lapped sides of hone....

I hope this helps/was interesting

-

The Following 2 Users Say Thank You to dinnermint For This Useful Post:

AljuwaiedAK (02-10-2016), Piet (02-10-2016)

-

02-09-2016, 05:35 PM #2Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,458

Thanked: 4830

It's a slippery slope once you start to have fun in the mud. I see more naturals in your future!

It's not what you know, it's who you take fishing!

-

02-09-2016, 06:33 PM #3

I'm recieving one as well, can't wait to try it out

Good to hear possitive review

-

02-09-2016, 06:49 PM #4Senior Member

- Join Date

- Sep 2014

- Location

- Bulgaria

- Posts

- 840

Thanked: 168

ho cut those hones , Vasilis is that you . looks good indeed

-

02-09-2016, 08:21 PM #5

Vermio; The Black, Greek hone

Vermio; The Black, Greek hone

Really like the Vermio, i always find the results well balanced between sharpness and smoothness....i prefer using oil or water/glycerine mixture with those..

Still one of the hardest types of "Slates" or "whatever" when lapping and cutting....

Never try to handsaw slurry stones [emoji23]

These are mine, the big one is a real Benchstone size...

And a detail vid of the stone itself...

http://youtu.be/cn-PV7lrU6cLast edited by doorsch; 02-09-2016 at 08:31 PM.

███▓▒░░.RAZORLOVESTONES.░░▒▓███

-

02-09-2016, 08:27 PM #6

Oh, I bet. Just from the saw marks, the cost is all labor into cutting!

Sounds like you're talking from experience.....

-

02-09-2016, 08:28 PM #7

I can tell you that you can surely lap it smoother! but what wont happen is that you can get a mirror polished surface like with some other stones (fex. Arkansas Stones).

The samples i sent out thruout germany were tried from different people. Most of the people were satisfied...we tried all different types of Variants of Lapping from WD Paper up to 2000/5000, using different rubbing stones to flatten the surface, usind SIC powders from coarse to fine, etc..

It was possible to flatten some areas partly finer but not the whole surface...

Still did not get a solution to find some other ways..███▓▒░░.RAZORLOVESTONES.░░▒▓███

-

02-09-2016, 08:30 PM #8

Vermio; The Black, Greek hone

Vermio; The Black, Greek hone

Iam sure that process is very hard and costs a very high effort besides quarrying the stuff....i well appreciate the work which was put into that project to create a nice alternative to other stones for some people!!

I wish that Project a golden Future because a lot of personal power and time from a nice guy was put into it!Last edited by doorsch; 02-09-2016 at 08:34 PM.

███▓▒░░.RAZORLOVESTONES.░░▒▓███

-

02-09-2016, 08:36 PM #9

You mean, if I try to lap the currently lapped surface with a finer W/D sandpaper, it'll be inconsistent along the stone?It was possible to flatten some areas partly finer but not the whole surface...

You mean, if I try to lap the currently lapped surface with a finer W/D sandpaper, it'll be inconsistent along the stone?It was possible to flatten some areas partly finer but not the whole surface...

You and me both!!! I'm tempted to buy a whole stack of them!i well appreciate the work which was put into that project to create a nice alternative to other stones for some people!!

-

02-09-2016, 08:42 PM #10

Yeah probably its just because of the composition of the stone, its hard to explain and you really have to tryout...

There are some stages where it tends to look really glossy sometimes it gets a bit mirror finished, but then there are small areas where you cant see any reflection....

Worked nearly 3 hours with the hard side of a Hybrid Coticule side with dishwater solution. Which worked quite good but ended not in the result i have wished....███▓▒░░.RAZORLOVESTONES.░░▒▓███

135Likes

135Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote