Results 1 to 10 of 22

Thread: Crack in a C-nat

-

08-24-2017, 07:30 PM #1

Crack in a C-nat

Crack in a C-nat

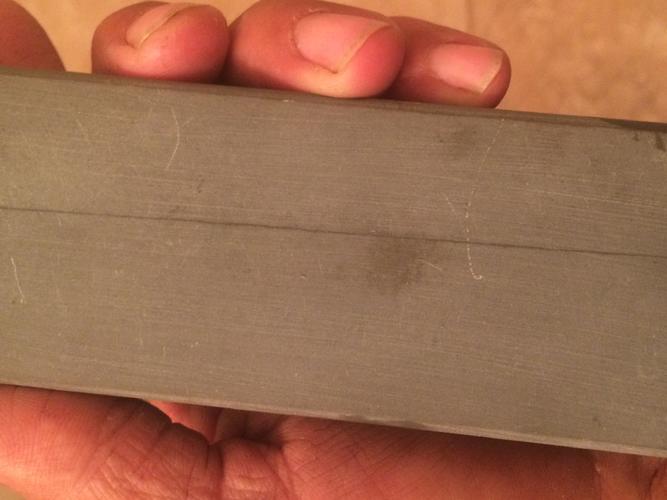

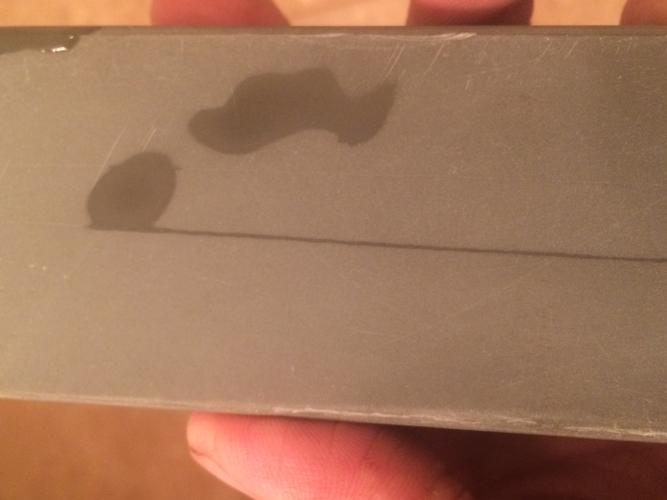

I noticed last night that my C-nat has a crack running down the length of the stone. It is all the way through the stone, but not the whole length yet. Somehow it is not hurting the finishing qualities of this stone. The stone is from woodcraft and says it's from the guangxi province. It is a good finisher and have used it on all my razors, and they all shave close and comfortable. Is there a way to save this stone from fully cracking? Or would it cost less to replace it for around $35? It is a very hard stone and very difficult to lap.

Bottom side

Top side

Thanks in advance on the help

-

08-24-2017, 07:39 PM #2Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

You could consider sealing it. In this case I would probably sacrifice the ability to use the back of the hone and glue it to a wood base too. It's easy to say 'just replace it cause they're cheap' but there's no guarantee the one you get will be as good as this one. So I would try to save it.

-

08-24-2017, 07:45 PM #3

Thanks Marshall. I only use the one side. It's just way too hard to lap to bother with the back. But I was thinking of using epoxy to adhere it it something, didn't think wood would work with the water involved with honing, warpage being my main concern. What type of epoxy and what to adhere it to? Are my main questions?

-

08-24-2017, 07:52 PM #4Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Wood is probably do-able if it's coated with a nice water resistant polyurethane sealer. Which is also what I used to seal the sides and bottom of my Jnat. So I was thinking glue to backer, coat both with sealer, and hopefully stop the crack in it's tracks.

Glass would probably also work. There are suggestions for glues to glass backers here:

http://straightrazorpalace.com/hones...ros-glass.html

I know it's not a Shapton Pro, but same principle I imagine.Last edited by Marshal; 08-24-2017 at 08:09 PM.

-

08-24-2017, 08:45 PM #5Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Glue it to a base. Stable wood or glass.

-

08-24-2017, 08:58 PM #6Sharp Minded Citizen

- Join Date

- Oct 2013

- Location

- Bucharest

- Posts

- 434

Thanked: 156

That's a strange way for it to crack...leads me t belive it was cut with the laiers running perpendicular to the stone face....

that means that you are looking at the layers when you look at the hone working surface...if this is the case and a layer separation has started it might go all the way trough in time no matter what you do....stone as basicaly any other material expands and contracts in response to temperature and hidratation....this is the way stones have cracked from the begining of time...

Cracks could be one of two...

Stable...cracks that are promoted by shock or handling during manufacturing practices...some mines just blow sp stock and pickup the pieces for cutting...like modern coticule mining

These cracks tend to be in healthy stones and are usualy stable.

Unstable cracks are usualy the result of mineral oxidaton in between the layers ...water and air sip in and the oxides usualy take up more volume then the original mineral and exert a pressure effect between the layers promoting a crack...the crack eventualy gets larger...oxidation accelerates and the stone finaly separates.

As the guys before said...best thing would be to let it dry...seal the crack with ca Glue..sand the excess off then seal this face and the sides and turn it arround and use the other face if it is usable.

Sealing usualy stops the crack progression.

Glueing it to a wood base has its advantages and disadvantages...you will have to find a way to seal the wood so that water does not promote cracks...if not sealed the wood expands and shrinks while it absorbs water and gets dry...this kind of tension and stress transferes to the glued hone in time....so it is important for the wood to be sealed.

Also if gluing it to a wood base is what you decide...do it in such a way as if you want to ever unglue it you can do it without breaking the stone.

If you decide to laquer it you should try a thick hard laquer that dries to a glassy hard finish...like cashew...or bar-top epoxy.

Thin layers of laquer usualy stop the water sipping in but are easier to chip and ware over time and eventualy they stop beeing airtight...a stone is hard and you usualy hit it against other hard stuff.

Thin laquer works well if you lighthandle the stone or for naguras...etc.

That's all you need to know actualy.

-

-

08-24-2017, 09:03 PM #7

That probably would work, once seals really good. Thanks marshal.

-

08-24-2017, 09:15 PM #8

Thank you ovidiucotiga! I'll find where to get my hands on some cashew laquer, and give it a go. But if it does end up cracking all the way it's not that big of a deal, as they are inexpensive. And also I do know more about what I am looking at for this type of hone, so I should be able to pick out another good one instead of just lucking out like when I bought this one.

-

08-24-2017, 09:27 PM #9Sharp Minded Citizen

- Join Date

- Oct 2013

- Location

- Bucharest

- Posts

- 434

Thanked: 156

Cashew you could get o ebay or maybe even find in the States althoug cashew is a good way to go it does require certain condtions to apply and has a long-ish curing time.

Bar top epoxy on the other hand is self leveling...cures a bit faster and i would say it can be aplied in a thicker layer with less of a problem on curing speed.

you decide ... read abouth both first.

-

The Following User Says Thank You to ovidiucotiga For This Useful Post:

Paul76 (08-24-2017)

-

08-24-2017, 09:39 PM #10Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Well, if it's glued to a base even if the crack did finish all the way through the stone it won't effect honing anymore than it does now. With both pieces stable relative to one another and lapped flat to one another you'd just have a miniscule negative space where the blade won't touch the stones. As long as one doesn't rise up above the height of the other it ought to be fine.

If course if you have a Woodcraft (or similar) carrier nearby and they're willing to let you open the boxes and hand select your stone you might be able to pick out one as good as - or better than - the one you've got now. So it's all relative.

Only reason I used polyurethane over anything else is I keep some on hand. I do a little wood work as a side hobby. So if there's ever a problem with the coating I can just sand it down and touch it up. No big deal. And my stones only get jostled about in plastic cases they really don't take hard knocks. I did build it up more than usual finish coating though, I think my Jnat got a good 5 layers and they weren't the usual thin coats. For comparison my hand carved 80 lb long bow got 2 thin coats.

24Likes

24Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote