Results 51 to 60 of 61

-

09-17-2015, 10:05 PM #51Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Circles are for removing metal, not a finish stroke. Stria from circles will be in random directions, leading to chipping. Use either Straight or X strokes to set an even stria pattern.

The 60 lap 1k bevel looks good, if the bevels are meeting.

You will have to do many more laps on the slate to remove all the 1k stria and re-set the bevels. Because we don’t know the grit, you will just have to do as many as it takes to remove, all 1k stria.

Do your final 1k laps heel leading, so you end up with an angular stria pattern, then when you hone on the slate straight, you can easily tell which stria is 1k and which is slate.

Once the 1k stria has been removed and the bevels are meeting, then do laps on the Chrome Oxide strop until all the slate stria has been removed, at least 50 laps and probably 100.

If you see some 1k stria that you missed with the slate, go back to the slate and remove the 1k stria.

Strop on Chrome Oxide until all the slate and 1k stria is removed, the edge is straight and bevels are still meeting fully.

If the edge get chippy from the Chrome Strop, add another layer of tape and do 5 light laps to set a micro bevel on the slate, and then strop on leather.

It may just be that your slate, is not that much finer than the 1K. What you have to remember about Natural Stones is the grit is random and made over millions of years. The stone is only as fine as the coursest grit. If the stone contains 90 percent 6k grit and 10 percent, 2k grit, it is a 2k stone.

When you post edge photos mark a spot on the blade, bevel and the tape so you can index the photos and are compairing the same spot each time.Last edited by Euclid440; 09-17-2015 at 11:38 PM.

-

09-20-2015, 08:20 PM #52Member

- Join Date

- May 2015

- Location

- Australia

- Posts

- 33

Thanked: 1

Thanks again for helpful advice. I had another honing session today, I continued to work on the 1k stria from last time. The welsh slate is said to be 8k-10k and I believe it. I did 100 half strokes and 80 X-strokes on slurry, then 20 half strokes without slurry, 7 laps on green paste (assuming Dovo paste equivalent to 4k hone), then more x-strokes to see how the edge behaves. All in all, I concluded that the 1k stria are very deep to remove with the slate. I need to spend even more time with the slurry and the green paste strop. I tried the microbevel but I might have overdone it.

^^^^Hone to microbevel, stropped and ready for shave test

I felt adventurous and did a shave test after confirming that it still shaves arm hair. One very rough feeling pass but it wasn't pulling or resisting much. Technically I shaved with my own honed razor but it was not acceptable in quality and comfort just yet.

Next time I will try to use the green pasted strop as intermediary hone and spend a looot more time with it before progressing to the slate and slurry. The slate is very hard and it takes lot of effort to make some slurry out of it. I like the process however and started reading about jnats and coticules with the intention to eventually replace the welsh slate.

-

09-20-2015, 08:53 PM #53

-

09-20-2015, 10:38 PM #54Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

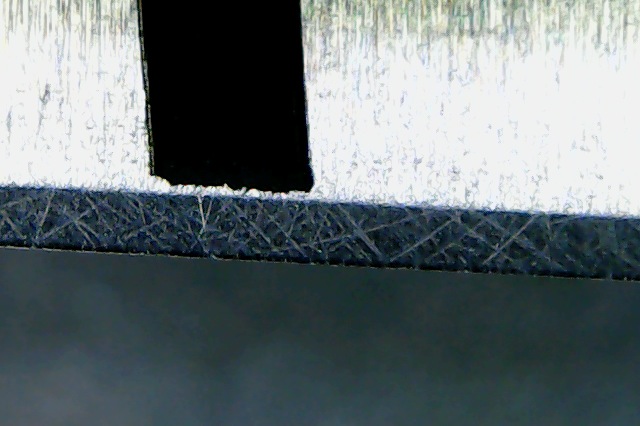

Yes, I know what they claim, but the ones I have tried are nowhere near 10 or 8K, 4-5 k at best with random heavier stria thrown in. The micro bevel photo shows a very rough edge, much of which is from the 1k heavy stria.

Do not use slurry, that also may account for the rough edge, as the slurry beats the edge. You have to remove all the deep 1k stria first, then build a new edge on the slate. The second photo clearly shows heavy 1k stria ending in large chips at the edge.

Here’s something you can try, take a good metal polish and paint 3 in X’s on a 12-14 in piece of cereal box type cardboard, use the unfinished inside.

Put the cardboard on the edge of a table or bench and strop on the metal polish until all the stria is removed from the bevels, may take 1-200 laps. The edge will be rough, but that’s ok, we want to see if the stria from the slate is fine enough to finish on by itself. Now do 10 straight laps on the slate, no slurry.

Look at the bevel and take a photo. It may just be the slate is not fine enough to finish an edge. If the stria is fine and in an even pattern, lightly joint the edge straight on a corner of the slate and re-set the bevel on the slate, and polish on Dovo paste.

Do not use the Dovo paste until after the slate, so you can tell which is the slate stria, and which is the paste stria. Ideally the Dovo paste stria is finer than the Slate, but who knows…They may be about the same…

If you are looking to make a finish stone purchase, a 12k Super Stone will easily produce a fine shaving edge, each and every time for less than the cost of a good Coticule and much less than a good Jnat. A good razor quality Chromium Oxide will refine and smooth the edge even finer.

-

10-16-2015, 07:24 PM #55Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

So, re-reading your post, I think the problem you are having. is the slurry.

As said those EBay “Welch” stone are of mixed grits and performance potential, and even if they slurry, they may not be “slurry stones”, for razor use.

I directed you to the Coticule.Be site as a source for using slurry but, a slurry stone, will only work if the grit is of the proper size and capable of being frangible, (easily breaking down), and friable (continue to break down to much finer grits), as you experienced adding un-friable Kng,1k slurry to the Slate stone. Bottom line, these slate stone are not Coticules, or even close in composition and performance.

A 1k King, is frangible will break down, (slurry to 1k loose grits), a Coticule and some Jnats are both Frangible and Friable, capable of breaking down and continue to break down, to much finer grits and polish the bevel and edge and of uniform grit.

If the grit will not break down, you are beating a fine edge on much larger grit, (think gravel), with each stroke and instead of refining the edge, you are damaging, chipping it.

A good slurry finish stone is of a uniform grit, if it contains larger grits, just a single large grit can leave a deep stria in the bevel that will leave a chip on the edge. You must determine if the stone is fine and uniform enough, to finish a razor on.

This is an interesting thread, I think there are a lot of guys in your shoes, trying to make these stones work and encountering all the issues you have.

Do post your results.

-

10-17-2015, 11:48 AM #56Member

- Join Date

- May 2015

- Location

- Australia

- Posts

- 33

Thanked: 1

-

10-19-2015, 10:51 PM #57Member

- Join Date

- May 2015

- Location

- Australia

- Posts

- 33

Thanked: 1

I forgot to post the above mentioned test I did to see the DT slurry/no slurry and Green paste effect on the scratch pattern. Minus the metal polish. Anyhow, here are the pictures for the interested.

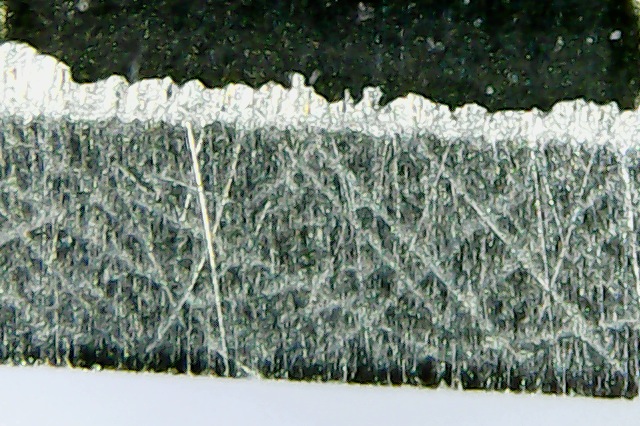

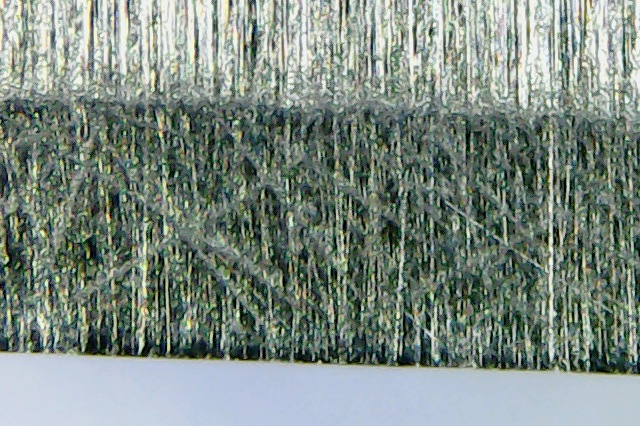

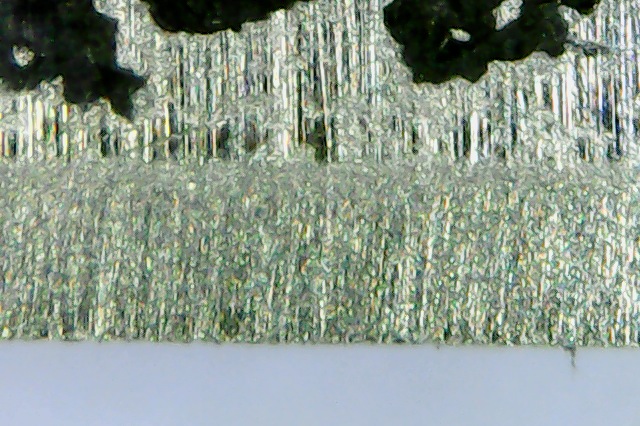

^^^200 toe leading angled laps on DT, no slurry. Vertical stria are from slurry strokes somewhere along the history, I believe.

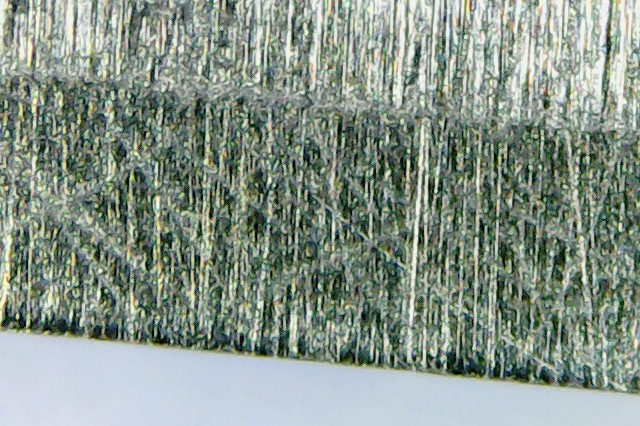

^^^20 laps on Dovo Green Paste

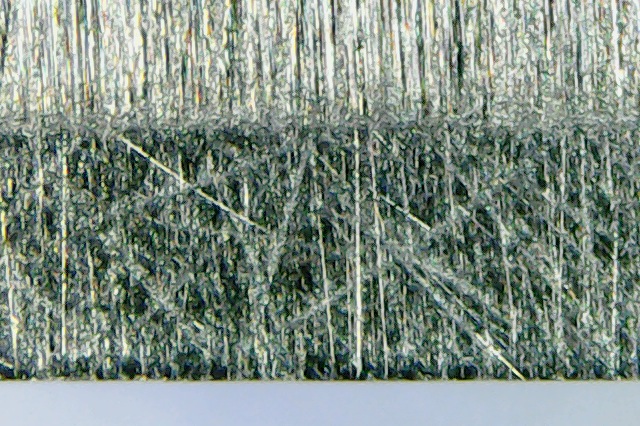

^^^100 laps on Dovo Green Paste

^^^20 toe leading angled laps on DT again, no slurry.

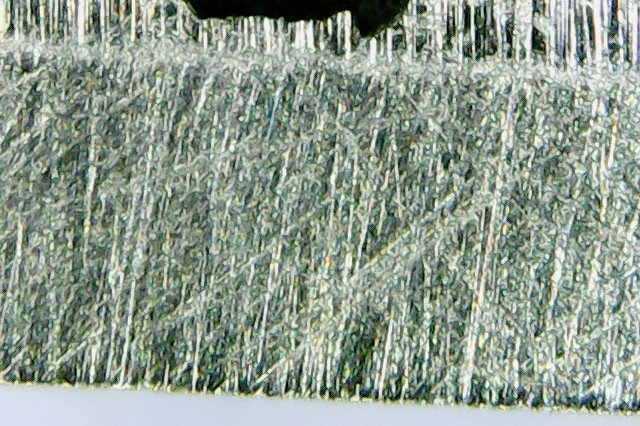

^^^60 toe leading angled laps on DT, with slurry.

I did a sharpie test for the whole bevel length and on about 3/4th of the length the sharpie markings disappeared only after 5-6 strokes, the 1/4th from the point did not.

I can't figure out if it's because

a) razor not held flat on hone b) not enough pressure c) lapping of hones on marble kitchen tabletop with #400 sand paper is not good enough

As I mentioned before, I bought a coticule and the same 3/4th issue is on that too. Haven't yet tried with another razor.

-

10-19-2015, 11:13 PM #58Member

- Join Date

- May 2015

- Location

- Australia

- Posts

- 33

Thanked: 1

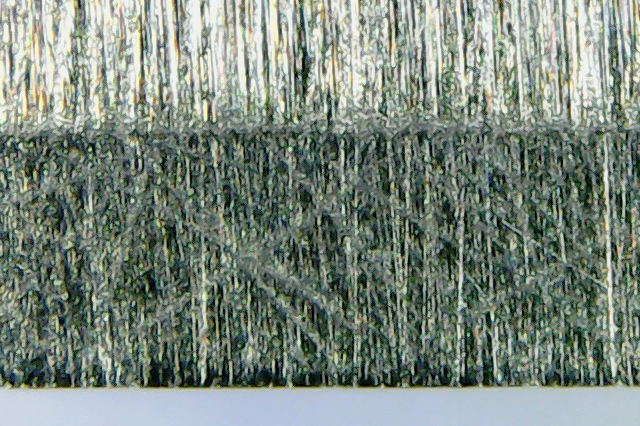

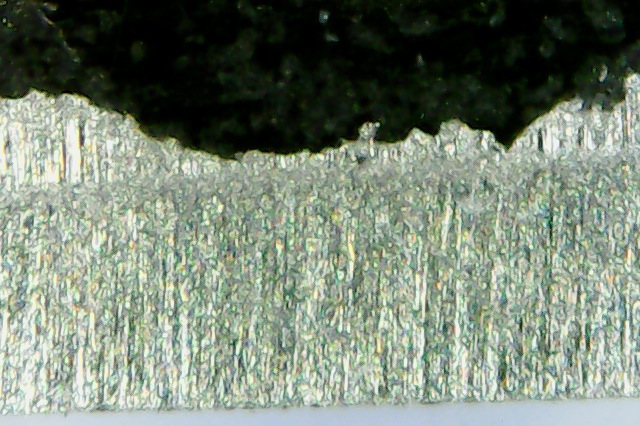

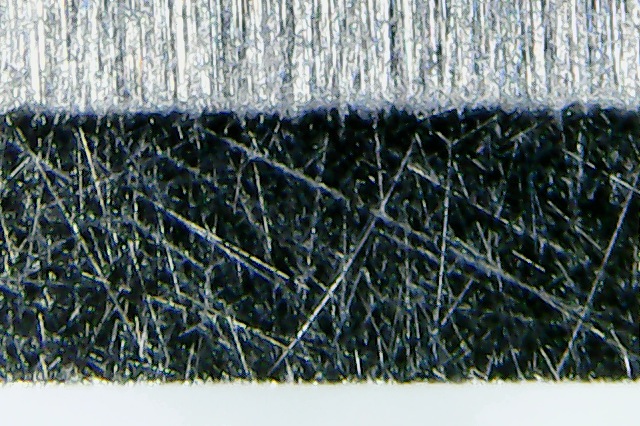

After three sessions on the coticule I made some improvement on the edge. Still not quite shaveable, though. Cuts arm hair, feels little bit sticky to thumb pad, cuts into thumbnail and does not slide. I am now tracking two locations and both sides.

^^^Location 1, roughly the same as my previous posts.

^^^Location 2, closer to the heel.

A whole different kind of beast this coticule but I already like it a lot. I rewatched the Lynn Abrams one-stone-method and he seems to much more pressure than I do. I have taken a second razor to practice with, a czech Mikov, on which I am still setting the bevel on 1k.Last edited by elmoensio; 10-19-2015 at 11:19 PM.

-

10-21-2015, 04:06 AM #59Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Edge looks a lot better, don’t think the DT is a finisher. Notice the uniform, finer stria pattern and all the diagonal stria gone…

Keep doing laps on the coticule with light or no slurry, 100 plus laps not uncommon especially with what you started with.

-

10-21-2015, 04:39 PM #60Member

- Join Date

- May 2015

- Location

- Australia

- Posts

- 33

Thanked: 1

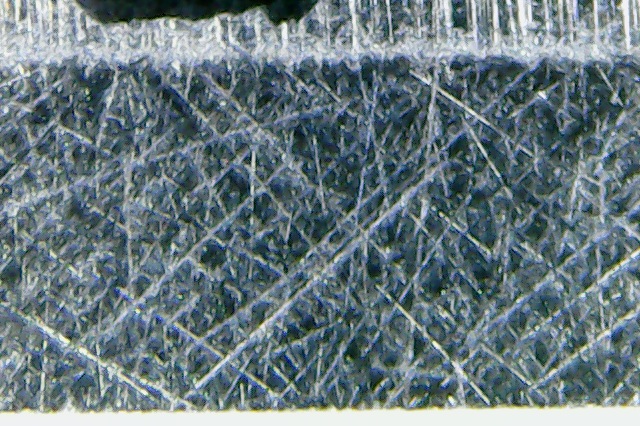

Today I spent some quality time with my TI and coticule. I started with very light slurry and then only on water. It started to show polishing, except on one side near the point. That looks almost untouched and I am not sure what to do with it.

^^^Near the point. One side seems much more polished than the other

^^^Near heel. Boths sides seem equally polished.

39Likes

39Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote