Results 3,351 to 3,360 of 3715

Thread: Hone of the Day

-

06-03-2020, 02:37 AM #3351

-

06-03-2020, 02:52 AM #3352Senior Member

- Join Date

- Jan 2015

- Location

- Apex NC

- Posts

- 535

Thanked: 90

-

06-03-2020, 03:19 AM #3353

-

06-03-2020, 04:02 AM #3354Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829

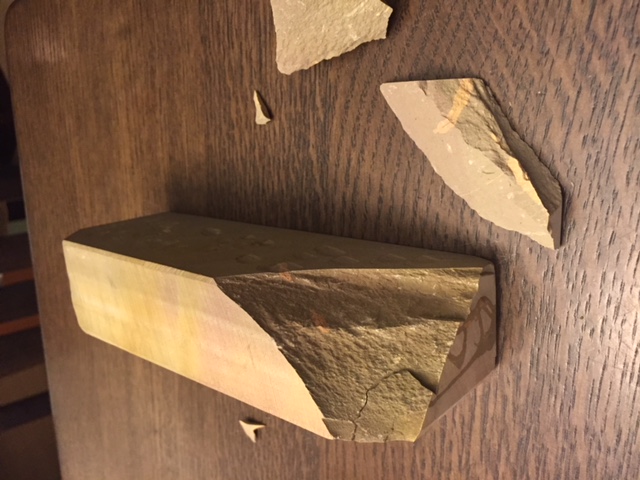

Itís hard to image how rough you have to be with the mail to break rocks, but they manage too. I had cut a very unique hone, and sure enough, they broke it. Ham fisted . . .

It's not what you know, it's who you take fishing!

-

06-03-2020, 04:10 AM #3355Senior Member

- Join Date

- Jan 2015

- Location

- Apex NC

- Posts

- 535

Thanked: 90

Yeah that sucks. Looks like a beautiful Iromono too. Alex said the same thing about those corners. He said on these stones sometimes just a simple bump on the corner can cause a layer to let loose. Although using his simple method of shipping he said he has never had an issue. I follow his method and usually add a little bubble too. Also another reason to seal those sides somethimes just to give some extra reinforcement.

Also looks like that stone had some Namazu running through it by the looks of that chunk. I had one break completely along the Namazu line and clean too. I think those may be a weaker point sometimes.

-

06-03-2020, 08:13 AM #3356

I think it is supposed to be 400 magnification.. Don't let the looks deceive you . The only one that really matters is the bevel set 1k. That's where i spend my time killing the edge and re setting until it pops arm hair and looks good under the scope. If it doesn't look good there are a number of checks to through . Bevel angle is normally what's wrong..Especially using fat tape on older blades restored..

When honing for a customer i take a before and after photo.. Jnat edges look amazing under the scope..

Thanks Mike

-

06-03-2020, 04:51 PM #3357

Damn that does turn your stomach! I would have to go fishing after that!

-

06-03-2020, 06:03 PM #3358

Those glassy lines and namazu lines are mineral filled cracks. They’re naturally weak and if a stone is subjected to stress, a lot of times that’s where they fail.

I’ve also had a Hakka tomo separate in my hand along the layer structure, no crack needed, it stuck to the hone because it wasn’t soaked long enough, and presto, I had two nagura, one in my hand and one stuck to the stone.My doorstop is a Nakayama

-

06-05-2020, 06:09 PM #3359

Today I finished this WH Oates in black horn on the unique, massive primitive black Arkansas stone that I got recently from Dan's Whetstones (which I gave more info. on the mounting process in the "What Are You Working On?" thread). The super-soft British steel on this razor took an easy, killer edge after a quick progression on water stones up to 8k, then using WD-40 on the highly burnished Ark surface. I purposely left out the Nani 12k step, as I'm intrigued to try this minimalist approach to edge retention and longevity that Shaun and others talk about. I look forward to the test-shave.

I also put on a 2nd layer of tape and set a micro-bevel on 4 others that felt like they needed something more-we'll see.There are many roads to sharp.

-

06-06-2020, 12:03 AM #3360

Last night, I set the bevel with the green brick, then took this 7/8 Wade & Butcher up to around 8k, using a Washita, and dark blue, Thurigan.

This evening, I finished it out on the B/G barbers delight.

Only thing left...shave test.!

Mike

Mike

23394Likes

23394Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote